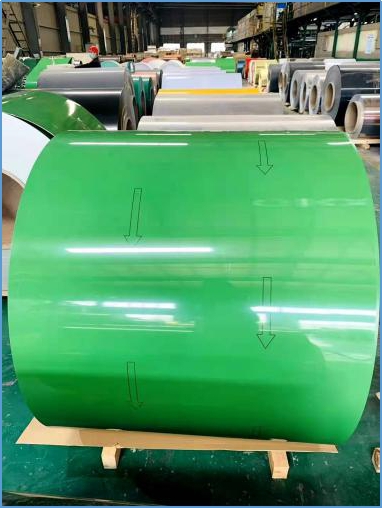

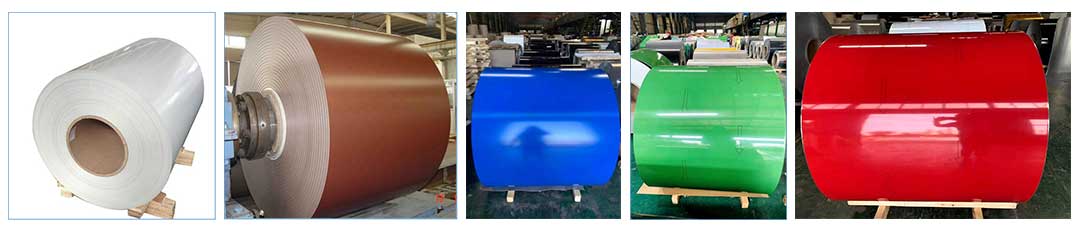

Color Coated Aluminium Coil

- Material: Alloy aluminium

- Property: Anti-corrosion, heat resistant, fireproof

- Surface: Polished, mirror finish

- Process: PE&PVDF

- Thickness: 0.04mm-3.0mm

- Width: 1200mm-2600mm

- ID: 6mm-505mm

- Standard: GBT3880-2012,AMS-QQA-250/12,AMS-4027,BS1470, ASTMB209, EN485 and JIS H4000

Product Description

Color coated aluminium coil (color coated aluminium), surface coating coloring treatment for aluminium plates or (aluminum coils). Commonly used are fluorocarbon color-coated aluminium (color-coated aluminum coils), polyester color-coated aluminium (color-coated aluminium coils), which are widely used in aluminium-plastic panels and aluminium sheets. Board, aluminium honeycomb panel, aluminum ceiling, roof surface, leftover material, cans, electronic products. Its performance is very stable and it is not easy to be corroded. The surface layer can be guaranteed for 30 years after special treatment. The weight per unit volume is the lightest among metal materials. Color-coated aluminium(pre-painted aluminium coil) is currently the most popular new type of material.

Features of Coated Aluminium Coil

| Product Name | Color coated aluminium coil |

| Material | Alloy aluminium |

| Property | Anti-corrosion, heat resistant, fireproof |

| Surface | Polished, mirror finish |

| Process | PE&PVDF |

| Thickness | 0.04mm-3.0mm |

| Width | 1200mm-2600mm |

| ID | 76mm-505mm |

| Standard | GBT3880-2012,AMS-QQA-250/12,AMS-4027,BS1470, ASTMB209, EN485 and JIS H4000 |

| Package | Export wooden pallets, craft paper, anti-blushing agent. |

| Application | Widely used in construction, building, exterior decoration, chemical equipment, cookware, billboard, household wares, welding parts, reflective devices, sheet metal processing parts, shutter system, container etc. |

| Delivery Time | 20-30 days |

| Payment Term | 30% TT down payment, 70% TT against BL copy or 100% LC at sight |

Advantages of the Coated Aluminium Coil

- Fluorocarboncolor coated aluminum coil (PVDF): The fluorocarbon coating is a coating of PVDF resin mainly referring to a vinylidene fluoride homopolymer or a copolymer of vinylidene fluoride and another small amount of fluorine-containing vinyl monomer. The chemical structure of the fluoric acid-base is combined by a fluorine/carbon bond. This chemical structural stability and firmness make the physical properties of fluorocarbon coatings different from conventional coatings. In addition to the abrasion resistance in terms of mechanical properties, impact resistance has excellent performance, especially in harsh weather and environment, showing long-lasting resistance to fading and UV. After the high-temperature barbecue is formed into a film, the molecular structure in the coating is tight and has excellent weather resistance. It is especially suitable for the decoration and display of indoor, outdoor decoration, commercial chain, exhibition advertisements, etc. in public places.

- Polyester coated aluminium coil(PE): The polyester coating formed by multiple baking of the surface of the aluminium plate can form a solid film adhered to have a protective decorative property. It is an anti-UV ultraviolet coating. The polyester resin uses a polymer containing an ester bond in the main chain as a monomer, and an alkyd resin is added. The ultraviolet absorber can be divided into a matt and a high-gloss series according to the gloss. It can give rich color to color aluminum products, and has good gloss and smoothness, as well as superior texture and hand feeling, and can also add layering and three-dimensionality. It can protect objects from ultraviolet radiation, wind, rain, frost and snow; the coating can protect due to temperature difference, freeze-thaw cycles, corrosive gases and microorganisms. Especially suitable for interior decoration and advertising panels.

Specification of the Coated Aluminum Coil

1.Alloy: 1100,1050,1060,1070,1200, 3003, 3004, 3005,3105, 5005,5052, 6061, 6082 etc

2.Temper : HO,H12,H16,H18,H24,H32,H36,T651,T4,T6

3.Thickness: 0.2mm-200mm

4.Diameters: 915mm-3000mm

5.Application: building, boat, truck, tanker, machine, etc.

Remarks: Specific requirements of alloy, temper or specification can be discussed at your request.

1.PE color coated aluminium coil:

Mainly used building decoration, such as ACP, aluminium, ceilings, aluminum sheets, honeycomb panels and aluminium roofing, lighting decoration, household electrical appliances, furniture, etc.

Thickness:0.04mm-3.0mm

Coating thickness:16-18Mic

Characteristic:

-High gloss

-Multi-choice colors

-Impact resistance

-Easy for processing

2.PVDF color coated aluminium coil:

Widely used for the decoration of the airport, exhibition halls, commercial buildings, star hotels and the curtain wall of high-class building

Thickness:0.18mm-3.0mm

Coating thickness:26-28Mic

Characteristic:

-Excellent weather-proof durability

-Anti-ultraviolet

-High erosion resistance

-Stable color and gloss

-Good mechanical processing performance

-Abrasion resistance

-Anti-impact

-High flexibility