Hot Sale Aluminium Coil Products

Features of Aluminum Coil

- Many Uses: Useful in construction, mechanical parts, forging, and welding because of its flexible traits.

- Chemical Composition: Contains high corrosion, heat, and wear resistance, alongside a low melting point.

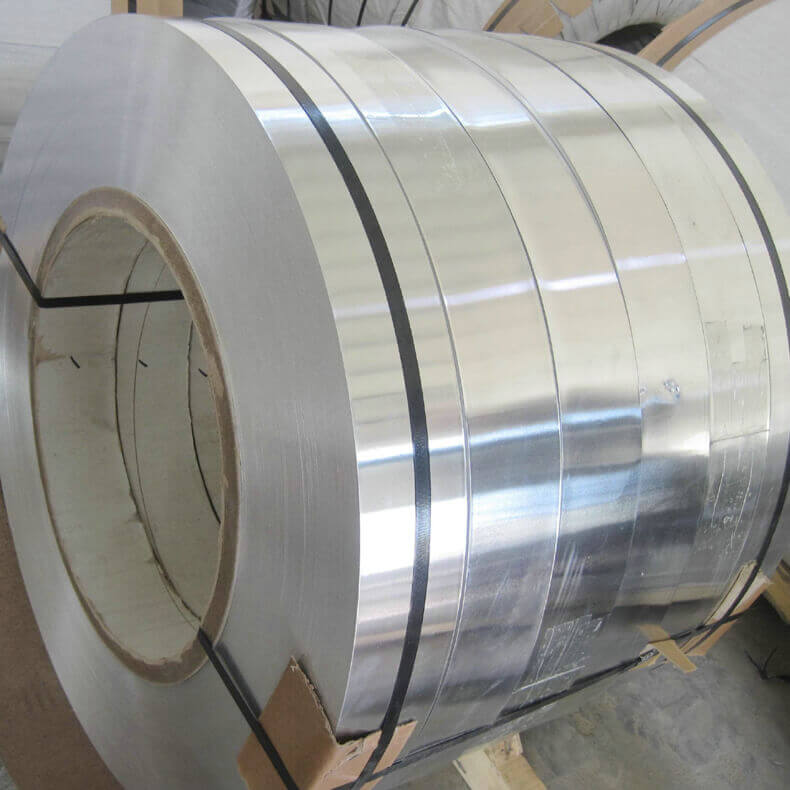

- Durability: Armoured aluminum coils with low density and high tensile strength foster ease in elongation. Strong yet lightweight and easy to process. Capable of slitting, arcing, balancing, drilling, joint-fixing, edge compression molding, and bulk cutting.

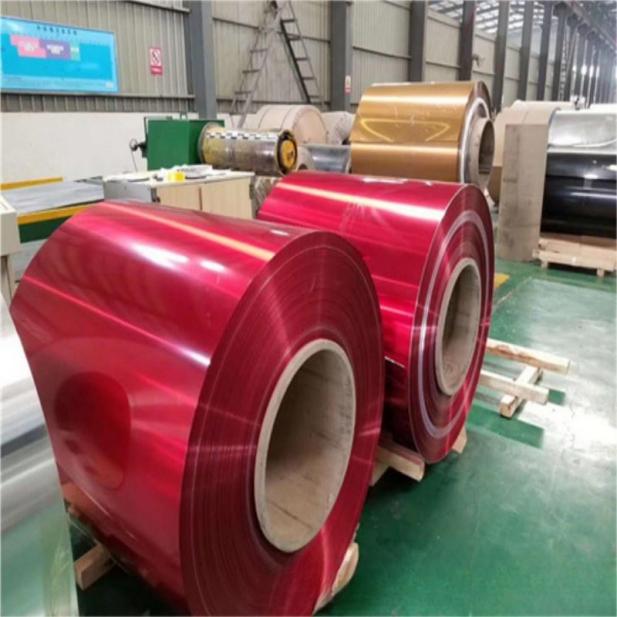

- Surface Treatment: Readily accepts paints, oxidation, and lamination, owing to the lack of oil, micro scratches, corrosion, surface waves, and other stains on the surface.

- Recycling: Of all metals, aluminum is the easiest to recycle as it retains its properties with repeated recycling. Can be used numerous times, making it a green material.

Specifications of Aluminum Coil

| Product Name | Aluminum coil |

| Alloy Number | 1050,1060,1070,1100,1200,1350, 3003,3004,3105,5052,5754,5083,8011 |

| Temper | O, H12, H14, H16, H18, H24 |

| Thickness | 0.2mm – 8mm |

| Width | 300mm-2600mm |

| Inner Diameter | 505mm, 508mm, 305mm, 76mm; Maximum OD: 2000MM |

| Standard width | 1000mm, 1200mm, 1220mm, 1250mm, 1500mm |

| Thickness tolerance | +/-0.02mm, Width tolerance: -0 / +2mm |

| Maximum weight per coil | 7 Tons |

| Standard | GB/T, ASTM, EN |

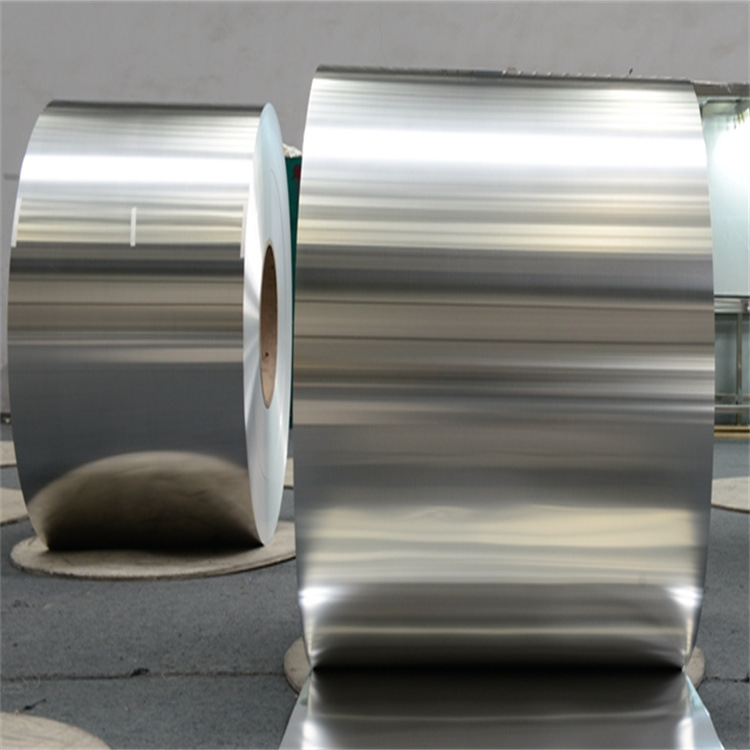

| Surface | Mill Finish, Anodized, Color coated PE Film Available |

| Packaging | Wooden Pallet for Strip & Coil |

| MOQ | 5T for customized, 2T for stock |

Aluminum Alloy Grade of Aluminum Coil

| Alloy Series | Introduction | Applications |

| 1000 Series | Industrial Pure Aluminum. Of all series, the 1000 series belongs to the series with the largest aluminum content. The purity can reach over 99.00%. | Chemical equipment, food and beverage packaging, architectural panels, heat exchangers, lighting reflectors |

| 2000 Series | Aluminum-copper Alloys. 2000 series is characterized by high hardness, in which the content of copper is the highest, about 3-5%. | Aircraft fittings, bus bars, electrical conductors, truck wheels, building components, marine fittings |

| 3000 Series | Aluminum-manganese Alloys. 3000 series aluminum sheet is mainly composed of manganese. The manganese content ranges from 1.0% to 1.5%. It is a series with a better rust-proof function. | Sheet metal forming, building products, kitchen utensils, electrical enclosures, chemical tanks, filing cabinets |

| 4000 Series | Al-Si Alloys. Usually, the silicon content is between 4.5 and 6.0%. It belongs to building materials, mechanical parts, forging materials, welding materials, low melting points, and good corrosion resistance. | Welding wire, filler metals, brazing sheet, building panels, food containers, chemical equipment |

| 5000 Series | Al-Mg Alloys. 5000 series aluminum alloy belongs to the more commonly used alloy aluminum series, the main element is magnesium, and the magnesium content is between 3-5%. The main characteristics are low density, high tensile strength, and high elongation. | Building materials, marine applications, storage tanks, pressure vessels, foil containers, sidings |

| 6000 Series | Aluminum Magnesium Silicon Alloys. The representative 6061 mainly contains magnesium and silicon, so it concentrates on the advantages of the 4000 series and 5000 Series. 6061 is a cold-treated aluminum forging product, which is suitable for applications requiring high corrosion resistance and oxidation resistance. | Aircraft components, building and construction materials, transportation applications, electrical enclosures, irrigation systems, consumer durables |

| 7000 Series | Aluminum, Zinc, Magnesium, and Copper Alloys. The representative 7075 mainly contains zinc. It is a heat-treatable alloy, belongs to super-hard aluminum alloy, and has good wear resistance. 7075 aluminum plate is stress-relieved and will not deform or warp after processing. | Aircraft structures, high-speed trains, truck wheels, sporting goods, aerospace components |

Factory Product Display Videos

Application of Aluminum Coil

Aluminum coils are widely used in auto parts, truck bodies, PS boards, building decorations, distribution cabinets, curtain walls, etc., due to their excellent plasticity and conductivity.

- Electronics and Packaging: They are integral in the electronics industry and various packaging applications.

- Construction and Machinery: Aluminum coils are essential in construction projects and mechanical applications, including machinery parts.

- Aerospace and Automotive: In aerospace, they are used for their lightweight yet strong characteristics. They are also employed in automotive heat dissipation systems and cable manufacturing.

- Consumer Goods and Household Items: Aluminum coils find applications in consumer products such as cookware, household wares, and kitchen utensils. They are also used in cosmetics packaging.

- Industrial and Infrastructure: Their use extends to industrial and infrastructure projects, including chemical equipment, billboards, and reflective devices. They are crucial in manufacturing shutter systems, containers, and transformer strips.

- Building and Decoration: They are prominent in building materials, exterior decoration, and construction, serving purposes in aluminium curtain walls, ceilings, honeycomb panels, and roofing. They are also used in lighting decoration, furniture, and ACP (Aluminum Composite Panel).

About Lanren Aluminium

Lanren Aluminium is engaged in the production of aluminium materials and aluminium cookware. Our aluminium production range includes aluminum coils and circles for various cookware.

Our products and services comprise of aluminum coils, sheets, composite materials, cookware sets, fry pans, pie pans, baking trays, cake molds, streamers, and aluminum circles which are customized as per the client’s requirements which include deep drawing circles, induction circles, and color coated circles.

We supply high-quality products which are competitively priced with great after-sales services. This has allowed us to build strong and loyal partnerships with over 80 countries, which include the USA, Canada, Australia, Mexico, Spain, France, India and South Africa. We also do OEM orders to provide tailored order solutions for our clients. We invite you to visit us and build strong and fruitful partnerships.

Why Choose Us

Sample Services

We offer free samples for testing, with the customer covering the delivery charge.

Customized Services

We welcome customized samples and boast a professional design team to meet your requirements.

Processing Service

Our processing services include bending, decoiling, welding, punching, and cutting.

After-sales Service

We have professional after-sales service personnel who will receive your suggestions 24 hours a day.

Aluminum Coil Packing and Transportation

- Standard airworthy export packaging. Wooden pallets with plastic protection for coils and plates;

- According to customer requirements, the packaging can face the sky or the wall.

- 16-20 MT can be put into 20FCL, the shipping price is much cheaper than 40FCL;

- Delivery time: 15-35 days after receiving the LC or 30% deposit.

Order Process of Aluminium Coil