Marine Aluminum Sheet

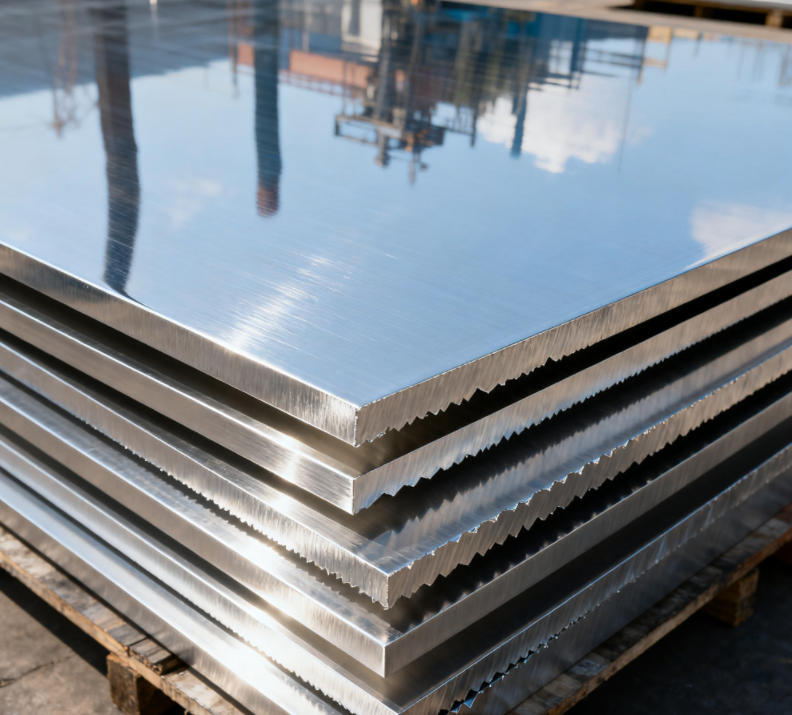

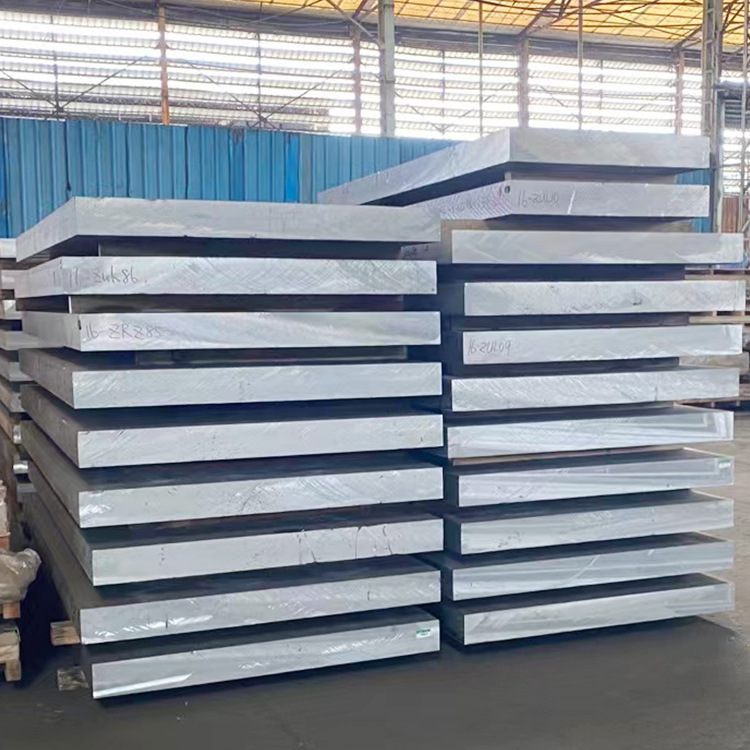

Marine aluminum sheet is a high-performance material designed for the marine environment. Marine aluminum sheet has anti-corrosion properties; you can use it in a water environment to build the side and bottom of the ship. Lanren supplies a variety of marine-grade aluminum sheets, suitable for different parts of the ship. These aluminum alloy sheets have different properties; you can choose according to your requirements.

Specification

| Specification | Typical Values |

| Alloy | 5083, 5052, 6061 |

| Temper | Soft HO, H12, H13, H14, H15, H16, H18, H19, H20, H111, H112, H114, H116, etc |

| Thickness | 1.6mm – 25mm |

| Width | 1000mm – 2000mm |

| Length | Custom |

| Surface Finish | Mill finish, anodized, painted |

Mechanical Properties

| Property | Units | Alloy 5083-H112 | Alloy 5052-H321 | Alloy 6061-T6 |

| Tensile Strength | MPa | 275-345 | 240-290 | 310-345 |

| Yield Strength | MPa | 205-265 | 180-220 | 275-310 |

| Elongation | % | 12-18 | 15-20 | 12-17 |

| Hardness | HB | 70-85 | 65-75 | 90-95 |

| Modulus of Elasticity | GPa | 70 | 70 | 70 |

| Shear Strength | MPa | 190-230 | 170-210 | 210-240 |

Features of Marine Aluminum Sheet

The outstanding corrosion resistance: corrosion from seawater and some industrial chemicals is suitable for long-lasting use in a very rough and tough industrial marine environment.

- Positive physical properties: Each series of aluminum is different from the other, having its own specialized field. The 7075 series has immense strength and resistance to wear, while the 6061 series has superb capability to be machined and welded.

- Benefit of being very light: Marine aluminum has a low density, thus reducing the aluminum hull of the ship, allowing it to use less fuel and carry more weight.

- Controlled material states: Temps like 5083-H116, which are controlled, have better armor for corrosion resistance and weldability to capture marine applications.

- Wide open use: All of these sheets are used to make hulls, decks, and the engine’s foundations, used in side and bottom plating.

- Dependable allux performance at low temperatures: All 5083 series alloys have propellable mechanical properties and are very suitable for ships in the icy polar regions.

- Anodized aluminum has a better added surface: Anodizing aluminum improves appeal and corrosion resistance.

These properties make marine sheets outstanding for use in high-performance marine frameworks. It is best to choose the material depending on the application to use the correct alloy and temper.

Main Application Areas of Marine Aluminum Sheet

- Shipbuilding & Hull Construction: Marine-grade aluminum sheets are extensively used for building hulls and superstructures of boats, ships, and ferries. Their high strength-to-weight ratio reduces the vessel’s overall weight, leading to greater fuel efficiency, higher speeds, and increased stability. This is crucial for high-performance crafts like crew transfer vessels and military ships.

- Decking & Superstructures: Aluminum sheets are fabricated into decks, walls, and roofs for ship superstructures. The material’s lightness helps lower the vessel’s center of gravity, improving seaworthiness and preventing top-heaviness. Its non-sparking property is also a critical safety feature on decks where flammable materials may be present.

- Offshore Platforms & Structures: In the oil and gas industry, aluminum sheets are used for constructing living quarters, helidecks, and modular sections on offshore platforms. Their corrosion resistance in the harsh marine environment, combined with their light weight, simplifies logistics and installation while ensuring long-term durability and reduced maintenance.

- Marine Transportation & Containers: Aluminum is a key material for building containers and cargo holds. Its resistance to saltwater corrosion protects goods from contamination, while its strength ensures structural integrity. The lightweight nature also allows for greater payload capacity, making transportation more economical.