Cable Aluminium Foil

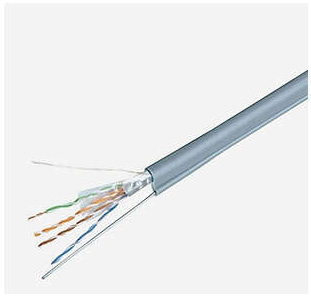

- Except for the outer jacket that protects against physical damage, a cable also has a shielding for protection against external signal interferences. These interferences may corrupt data transfer or create unwanted noise in an audio signal. Different types of shielding are used, as they differ in their specific advantage in protecting signal frequencies.

- Lanren Aluminum foil shielding is ideal for reflecting electromagnetic interference (EMI) and is often used in combination with a braided wire to absorb EMI.

Cable aluminium foil is a thin, high-performance aluminum material specifically designed for communication and electrical cables. As a key component of cable construction, it performs two functions that include electromagnetic interference (EMI) and radio frequency interference (RFI) shielding, as well as insulation to safeguard the transmission of signals. It is made of pure aluminum or alloys such as 1060 and 8011. Lanren’s cable aluminium foil is flexible, has durability against corrosion, and uniform thickness, ensuring long-lasting performance in tough environments (high temperatures, humidity, or mechanical stress).

Mechanical Properties of Cable Aluminium Foil

| Alloy | Temper | Gauge(mm) | Tensile testing | |

| Tensile Strength(Mpa) | ElongationA/% (more than) | |||

| 8011 | O | 0.0065-0.050 | 40-80 | ≥2.0 |

| 1235 | ||||

| 1145 | ||||

| 8079 | ||||

Typical gauge (T)

| Gauge range | 0.0065-0.050mm |

Product Tolerance on Size

| Dimension | Gauge(%) | Width(mm) |

| Tolerance | +/-5 | +1, -0 |

Pin Requirement

| Category | Pin Counts(pcs/㎡)less than |

| Gauge(mm) | Aluminum Foil for Cigarette Packing |

| 0.0065 | 400 |

| 0.007 | 300 |

| 0.0075 | 50 |

| 0.009 | 30 |

| >0.009-0.011 | 20 |

| >0.011-0.015 | 10 |

| >0.015-0.020 | 5 |

| >0.020-0.050 | 0 |

Why Choose Lanren’s Cable Aluminium Foil?

High-Performance Shielding: It has an efficiency of shielding that is greater than 90dB (at 100MHz-1GHz). It stops EMI/RFI interference from external devices (e.g., transmitters, motors) and stops signal leakage within sensitive cables (fiber optics or cable for data). This guarantees the stable transmission of signals in 5G communication systems as well as the power distribution system.

Excellent insulation properties: The smooth surface of the foil and its consistent size minimize the electrical conductivity between cables, which prevents short circuits. It is compatible with insulation materials such as PVC and PE and improves the overall security of the cable.

High Flexibility and processing capability: The annealed (O Tai ) or semi-hard (H24) temper permits easy wrapping, slitting, or laminating with film (PET, LDPE). Even at the thinnest gauges, it can resist tears during cable extrusion.

Corrosion and Temperature Resistance: Alloy 8011 is a combination of manganese and iron, enhancing resistance to chemicals, moisture, and temperature -ideal to use for cables used outdoors (power cables) or automotive electrical wiring.