Induction Aluminum Circle

- Alloy: 1050,1060,1070, 1100,1200, 3003, 3004,5052, 8011 etc

- Temper: O, H12, H14,H16,H18,H22,H24,H26,H32 etc

- Thickness: 0.4mm-10mm

- Diamters: 20mm-1380mm

- Application: kitchen utensils, stock pot, frying pan, rice cookers, lighting lamp, traffic sign. etc.

- MOQ:500kgs per size

- Certification: ISO9001/SGS/FDA

Product Description of Induction Aluminum Circle

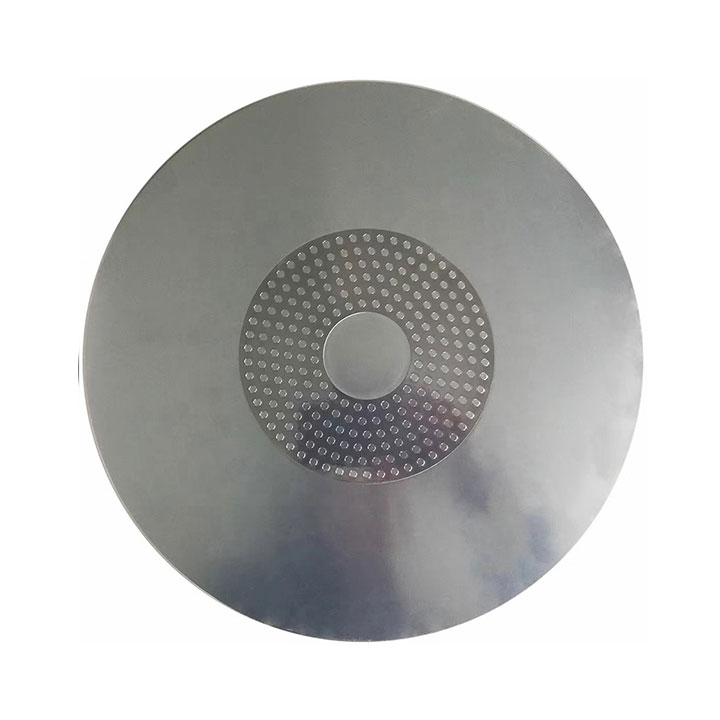

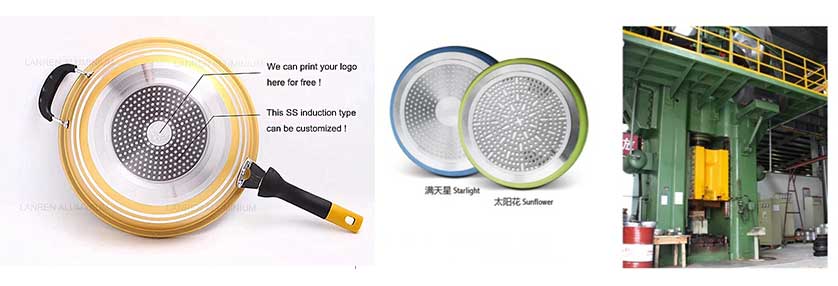

Our Induction Aluminum Circle stands out due to the latest bottom-coating technology and high-quality stainless steel bottom-coating. We use 410 grand steel for the bottom coating, a material renowned for its exceptional properties. It has high hardness, toughness, good corrosion resistance, and most importantly, excellent heat resistance.is very suit for cookware.

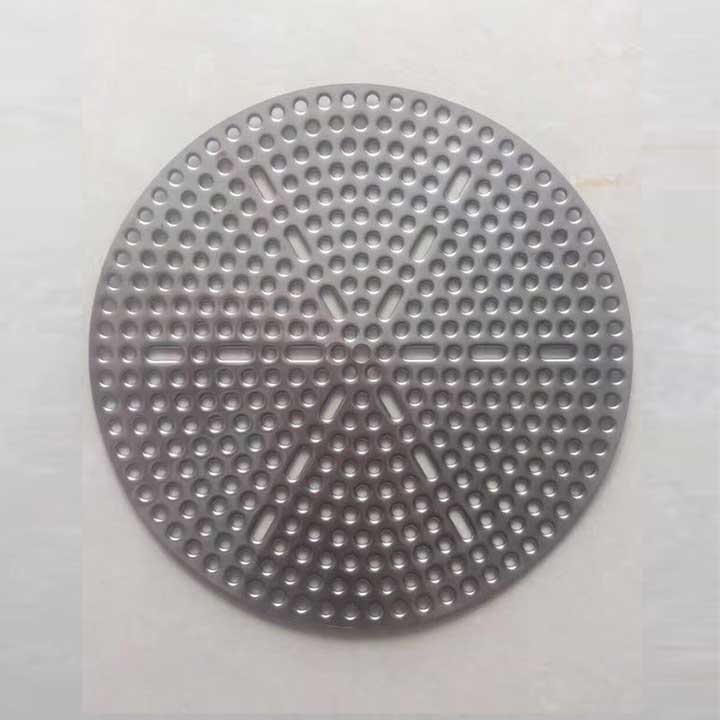

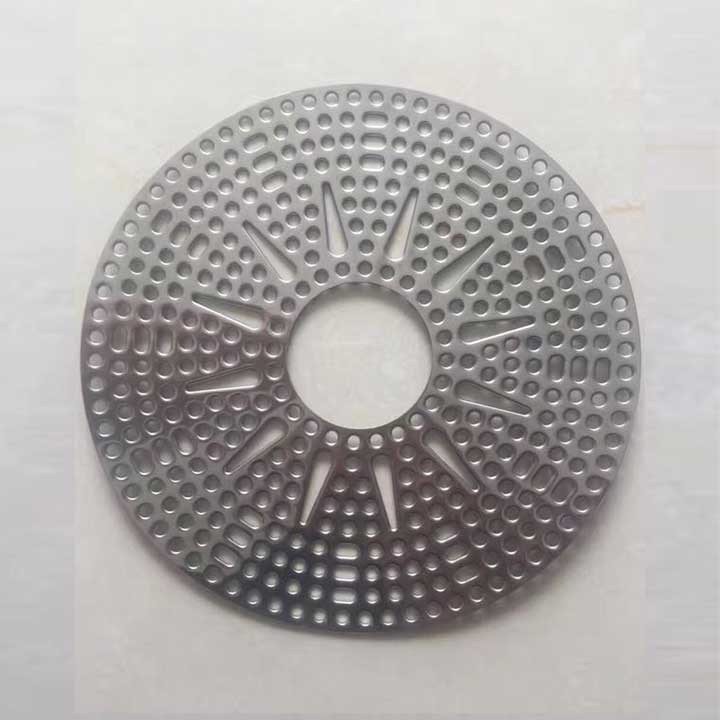

The thickness of our company’s induction aluminum circle will be 0.4mm, and the most widely used diameter we can provide is 85/101/114/131/144/147/161/178/191mm. We also have different types of shapes for Stainless steel parts such as sunflower, starlight, etc., adding a stylish touch to your products. In our factory, we’re equipped with two advanced circle blanking presses, combined with open shear processing.This setup gives us the flexibility to produce a diverse range of aluminum circles, allowing us to serve different markets worldwide.

Specification of Induction Aluminum Circle

(1)Induction Aluminum Circle detail

| Product | Induction Aluminum Circle |

| Circle Alloy | 1050 1060 1070 11002014 3003 4047 5005 5052 5454 6061 7075 8011 |

| Induction Alloy | 410 |

| Temper | O, H12, H14, H16,H18,H24,H32,H36 |

| Thickness | 1.0mm-4.0mm |

| Circle Diameter | 200mm-600mm |

| Induction Diameter | 85,101,114,131,144,147,161,178,191mm |

| Type | Bright & smooth surface, free from defects like white rust, oil patch, and edge damage. |

| Lead Time | Within 30-45 days after receiving deposit |

| Packing | Export standard packaging: wooden pallet + cardboard + steel bar fixed |

| Material | Using high-tech machinery utilizing premium grade aluminium Coil. |

| Surface | Bright & smooth surface, free from defects like white rust, oil patch, edge damage. |

(2)Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | V | Others | Al |

| 1100 | Si+Fe:0.95 | 0.05-0.2 | 0.05 | / | / | 0.1 | / | / | 0.15 | 99 | |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | / | 0.05 | 0.03 | 0.05 | 0.03 | 99.5 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | / | 0.05 | 0.03 | 0.05 | 0.03 | 99.6 |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | / | 0.04 | 0.03 | / | 0.03 | 99.7 |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | / | 0.15 | Others |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | / | / | 0.1 | / | / | 0.15 | Others |

| 4047 | 11-13 | 0.8 | 0.3 | 0.15 | 0.1 | / | 0.2 | / | / | 0.15 | Others |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | / | / | 1.15 | Others |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | / | 0.15 | Others |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.2 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | / | 0.15 | Others |

| 8011 | 0.5-0.9 | 0.6-1.0 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | 0.08 | / | 2.15 | Others |

(3)Different alloy applications

| Alloy Series | Alloy | Typical Application |

| 1XXX | 1050 | Industrial device and storage vessel, tank, etc. |

| 1100 | ||

| 2XXX | 2014 | Aerospace structural parts, cabinet Shelley building and transportation vehicle, mechanical parts |

| 2024 | ||

| 3XXX | 3002 | Handling and storage device for chemicals, liquid transportation, curtain wall and radiator, pressure vessel and tubing, |

| 3004 | Production and storage device for chemicals, building panel, cable and tubing, etc | |

| 5052 | Metal sheet for marine and transportation vehicles, inner and outer siding, the board of railway carriage, the storage device of oil and chemical industry, equipment panel and medical machinery, etc. | |

| 5A02 | ||

| 5754 | Inner and out siding, bedplate and board of railway carriage, transportation, etc. | |

| 5XXXX | 5086 | Board, siding and deck of ship side and bottom, etc |

| 5083 | Board, siding and deck of ship side and bottom, bedplate and board or railway carriage, welded parts of the ship, automotive and aircraft panel, cooling device, tower body of oxygen generator, structural parts of pressure vessel, tanker, oil storage tank and material storage tank of oil and chemical industries, mold for automotive tyre, etc. | |

| 5A05 | Ship structure, marine facilities, transportation tanker, pressure vessel and flange wiring board, etc | |

| 5A06 | ||

| 6XXX | 6061 | Inner and out siding, bedplate and board of railway carriage, industrial molding, automation mechanical parts, testing instrument, supporting plate of electronics jig and tool, equipment parts of semi-conductor, etc. |

| 6082 | ||

| 6063 | Bed plate of a commercial vehicle, roof framework, transporter and transship | |

| 7XXX | 7050 | Radar structural parts, manufacturing structure of aircraft, other high-stress structural elements wiki demand high strength and strong corrosion-resistance, etc. |

| 7075 | Aviation, aerospace, molding, mechanical equipment, tooling and fixture, etc | |

| 8XXX | 8011 | Bottlecap/capsule, aluminum pilfer proof cap, lug cap, rip cap, screw cap, etc. |

Features of Induction Aluminum Circle

- Crafted from high-grade stainless steel, our induction aluminum circle can heat up quickly and distribute heat evenly across the surface;

- The other side of the induction aluminum circle can be coated with non-stick cookware, which is wear-resistant, not easy to rust, and will not produce compounds harmful to human health.

- Choose from a range of attractive patterns for the stainless steel cover, such as sunflowers, Star Light, rice-shaped and other exquisite shapes, fashion trends;

- Manufactured to strict German process standard production technology, our induction aluminum circle prioritize safety and reliability, and user convenience;

- We offer a wide range of sizes to fit various needs:Disc diameter:200-600mm, induction diameter:85/101/114/131/144/147/161/178/191mm, the thickness 1.0-4.0mm and other sizes to meet your various needs;

- Our Products are packaged to withstand domestic sales and international export standards;

- The good control of grain size and elongation in the early stage ensures that the induction aluminium circle of the deep drawing and spinning performance effectively avoids the late processing that may occur when the drawing, lotus leaf, and the ear rate of the high bad phenomenon. and can be used in the manufacture of cookware products, such as frying pans, sets of pans, high pans, non-stick pans, and so on.

Advantages of Induction Aluminum Circle

- We exclusively use brand-new aluminium ingots to ensure that all production lines in the factory are clean and that the products are free of impurities, so that the aluminium circles are of high purity.

- Need specific dimensions or unique features? We welcome custom orders, and the best part? There’s no mold fee!

- Our aluminium induction circles feature an excellent surface quality. We make sure they’re free from visible scratches, oil stains, oxidation marks, and dark spots.

- With a thickness of > 1.0 mm, our aluminium induction circles are robust and durable.

- We carefully monitor and control the alloy composition, state, and performance of our coils, to ensure the accuracy and diversity of aluminium circle provided.

- Equipped with the latest production machinery, we’ve significantly boosted our efficiency. Our advanced equipment not only increases the production speed of aluminium circle sheets but also improves material utilization.

- We’ve categorized our aluminium circle sheets based on various uses and requirements.This makes it simple for you to find the exact type you need, saving you time and effort in the selection process.

- Our products adhere to strict environmental standards, including ROHS and REACH.

Packing&Delivery

1) Standard airworthy export packaging. Wooden pallets with plastic protection for coils and plates;

2) According to customer requirements, the packaging can face the sky or the wall;

3) 16-20 MT can be put into 20FCL, the shipping price is much cheaper than 40FCL;

4) Delivery time: 15-35 days after receiving the LC or 30% deposit.

Why Choose Us?(About Company)

When it comes to induction round aluminum discs, Lanren Aluminum stands out as a trusted partner for cookware, appliances, and lighting projects. Here’s why customers keep coming back: we use pure aluminum and 410 grade stainless steel for the bottom—ensuring durability, heat resistance, and compliance with ROHS and REACH standards. Need specific sizes? We offer thickness 1.0-4.0mm, diameters 200-600mm. Enjoy free logo printing on your discs and free mold fees. Whether you’re making cookware, lighting reflectors, or appliances, we’re here to deliver discs that perform—on time, every time.

FAQ

Q1: Are you a trading company or manufacturer?

A: We are a factory established in 2008 and it is located in Nanping Industrial Park, Nanchuan District, Chongqing. We are the leading Aluminum cookware manufacturer in the west of China.

Q2: Can you send samples?

A: Yes, we could offer the free samples but freight collection.

Q3: What product information do I need to provide?

A: You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q4: How long does your delivery time take?

A: In general, our delivery time is within 30-45 days, and may be delayed if the demand is extremely large or special circumstances occur.

Q5: Can I go to your factory to visit?

A:Absolutely! We welcome global customers to tour our facilities. Note that some areas of the factory may be restricted.

Q6:What is your working time?

A: In general, our online service time is Beijing time: 8:00 AM-22:00 PM, after 22:00 PM, we will reply to your inquiry during the next working day.