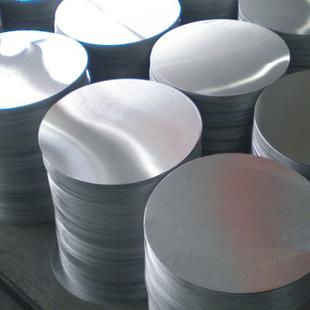

Product Description of Lighting Aluminum Circle

Aluminum circles have excellent deep drawing qualities and find wide applications in the lighting sector. These round aluminium products are used in the manufacture of a variety of lampshades including recessed lighting fixtures, industrial lighting equipment, sports venue lighting, and traffic light reflectors. Lighting aluminium circles are used as bases or frames in the manufacture of lighting fixtures such as ceiling lights, chandeliers and pendants. These discs play a vital role in securing light sources, bulbs or LED components.

Specification of Lighting Aluminum Circle

| Application | utensil, kitchenware, cookware, signboard, lampshade, panel |

| Product Name | Lighting Aluminum Circle |

| Alloy | 1050 1060 1100 3003 5052 |

| Temper | O, H12, H14,H16,H18,H22,H24,H26,H32, etc. |

| Type | DC&CC |

| Thickness | 0.4mm-10mm |

| Diameter | 20mm-1380mm |

| Surface Treatment | Mill finish |

| Processing Service | Bending, Decoiling, Welding, Punching, Cutting |

| Delivery Time | 30 days |

| Sample | Sample freely |

| Packing | Standard Seaworthy Wooden Pallet |

| MOQ | 500kgs per size |

| Certification | ISO9001/SGS/FDA |

Features of Lighting Aluminum Circle

- Excellent elongation and tensile strength, making them ideal for in-depth processing techniques like anodizing, wire brushing, enameling, and other similar treatments.

- High plasticity, electrical conductivity and uniform thermal conductivity.

- Offering outstanding durability and corrosion resistance.

- High manufacturing precision, small thickness and direct tolerance range.

- Smooth surface.

- Beautifully packaged, ensuring products reach you in perfect condition.

Advantages of Lighting Aluminum Circle

Suitable for bare finish application or normal finish application. Bare Finish: Showcases the natural luster of aluminium, ideal for modern designs. Normal Finish: Increases durability and protects against corrosion and wear, ideal for outdoor use.

Quality Control

Lanren Aluminum has established a strict quality control system in the production process of aluminium circles.

Our rigorous quality checks effectively avoid common issues like orange peel, hemming, and lotus leaves occurred during deep drawing or spinning in the later processing of customers. The 1060 aluminum disc from Lanren aluminum meets the highest quality standards, and our product pricing is competitive in the market.

When it comes to quality control, we spare no effort. We have developed a reliable and efficient shipping process. We keep our customers updated throughout the entire process to ensure that orders are delivered on time.

Why Choose Us?(About Company)

- Chongqing Lanren Aluminium Co., Ltd was established in 2008, and is located in the industrial zone of Nanping, Chongqing City, an Aluminium city.

- Our company occupies an area of nearly 50,000 square meters and has more than 300 employees, and Lanren has become a comprehensive aluminium fabrication enterprise for its production scale, advanced equipment, and full-range product varieties in China.

- We are able to supply aluminium coil, aluminium sheet, aluminium circle, aluminium composite, cookware sets, aluminium fry pans, aluminium pie pans, aluminium baking trays, cake molds, and aluminium streamers, and we can also supply different sizes of aluminium deep drawing circles, aluminium induction circles, and aluminium color-coated circles. Main products: aluminium water heater drain pan, aluminium pizza pan, aluminium milk can, aluminium streamer set, aluminium 5 pcs set pot, and aluminium stock pots.

Packing&Delivery

1) Packaging: We use standard seaworthy export packaging, including pallets with plastic protection for coils and plates;

2) Custom Options: The packaging can be customized according to customer requirements, such as facing the sky or the wall.;

3) Shipping:16-20 MT can be packed in 20FCL, which is more cost-effective than 40FCL;

4) Delivery time: 15-35 days after receiving the LC or 30% deposit.