Product Description

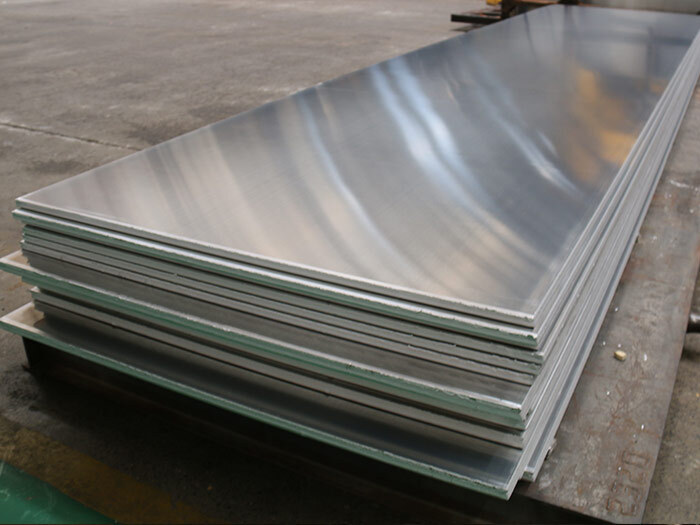

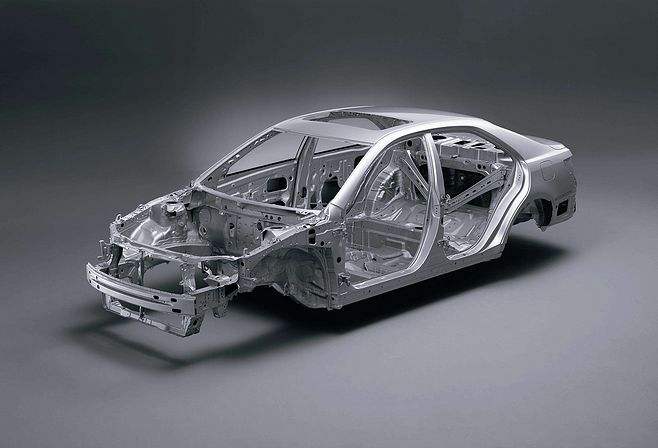

Aluminum sheet has become a popular choice for automobile panels due to its exceptional properties. Its lightweight nature contributes to improved fuel efficiency, making it a crucial component in the pursuit of greener vehicles. Additionally, aluminum’s excellent formability allows for complex shapes and designs, enabling car manufacturers to create aesthetically pleasing and functional vehicles. Furthermore, aluminum is highly resistant to corrosion, ensuring the longevity and durability of the vehicle’s exterior. These combined benefits make aluminum sheet an indispensable material in the automotive industry.

Specifications

- Physical Properties

| Property | Typical Range | Units |

| Thickness | 0.5 – 3.0 mm | mm |

| Width | 1000 – 2000 mm | mm |

| Length | 2000 – 6000 mm | mm |

| Density | 2.7 g/cm³ | g/cm³ |

| Tensile Strength | 150 – 300 MPa | MPa |

| Yield Strength | 100 – 250 MPa | MPa |

| Elongation | 15 – 30% | % |

| Hardness | 50 – 100 HB | HB |

- Chemical Composition

| Element | Aluminum (Al) | Copper (Cu) | Manganese (Mn) | Silicon (Si) | Iron (Fe) | Magnesium (Mg) | Zinc (Zn) | Other elements |

| Typical Range (wt%) | 99.0 – 99.7 | 0.1 – 0.5 | 0.1 – 0.5 | 0.1 – 0.5 | 0.1 – 0.5 | 0.1 – 0.5 | 0.1 – 0.5 | <0.1 |

Features

The characteristics of using aluminum sheets for automobile panels mainly include the following points:

- Lightweight advantages: The density of aluminum plates is about 1/3 of steel. Using aluminum plates can significantly reduce the weight of the car, thereby improving fuel efficiency and vehicle performance.

- Good corrosion resistance: Aluminum materials have a natural protective oxide layer, which can provide good corrosion resistance even in harsh environments and extend the service life of automobile parts.

- High strength and plasticity: Specific series of aluminum alloys (such as 6000 series) have high strength and good formability, and are suitable for the manufacture of automotive panels.

- Recyclability: Aluminum materials are easy to recycle and reuse, helping to reduce environmental pollution and resource consumption, and meet the requirements of sustainable development.

- Good surface treatment performance: Aluminum plates can be subjected to surface treatments such as anodizing and spraying to improve wear resistance and aesthetics and adapt to the needs of automobile appearance design.

- Energy saving and environmental protection: The processing and recycling process of aluminum materials consumes less energy, which helps to reduce energy consumption in the production and use of automobiles.

- Improved safety performance: The high strength and good energy-absorbing capabilities of aluminum materials help improve the car’s occupant protection performance in collision accidents.

- Cost-effectiveness: Although the initial investment may be higher, due to the lightweight and energy-saving properties of aluminum, cost-effectiveness can be achieved in the long term through reduced fuel consumption and maintenance costs.

In summary, the application of aluminum plates in automotive panels provides a series of engineering and environmental advantages and is an important material choice for achieving lightweight vehicles and improving overall performance.