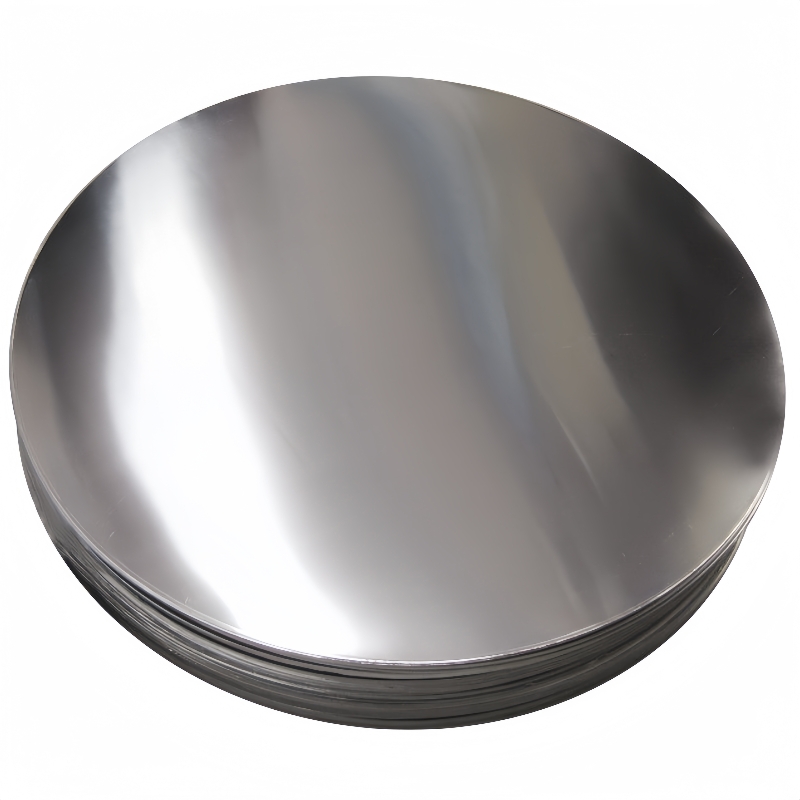

Aluminium Circle for Spinning

- Temper: O、H12、H14、H16、H18、H24、H32、H36

- Width: 60mm-1200mm, Customized

- Thickness: 0.4mm-10mm

- Surface Treatment: Mill finish, coating

- Alloy: 1000, 3000, 5000, 6000 series, etc

- Applications: Suitable for making pots, pans, pizza pans, pie plates, cake pans, lids, kettles, basins, fryers, and reflectors.

The aluminum circle used for spinning forming depends on the feed motion of tools like rotating wheels, which apply pressure to the aluminum circle blank. This blank, rotating along with the machine spindle, undergoes continuous localized plastic deformation, ultimately transforming into the desired hollow rotary components. The process involves few types and does not require cutting techniques.

Chongqing Lanren Aluminium Co., Ltd is a professional manufacturer of Aluminium circles for spinning, with advanced manufacturing equipment, capable of producing high-quality aluminum circles.

Features of Aluminium Circle for Spinning

- Our aluminum disc is specially designed for the spinning process, with excellent ductility and plasticity, and can easily achieve the required shape and thickness during the spinning process. Whether you’re working on intricate designs or simple forms, this disc ensures a smooth and efficient spinning experience.

- The thickness and composition of the aluminum disc are uniform. This means the final spinning product always has stable, reliable quality.

- The surface is specially treated with high finish, suitable for further processing and decoration, such as polishing, spraying, etc.

- While ensuring good processability, the aluminum disc also has high strength and toughness, meeting the performance requirements of various spinning products.

Advantages of Aluminium Circle for Spinning

- Improve production efficiency: Our aluminum wafers are a spinning pro’s dream. Because our aluminum wafers have good spinning adaptability, the efficiency of spinning production can be significantly improved and the scrap rate can be reduced.

- Reduce production costs: Say goodbye to wasted materials. Uniform thickness and composition help reduce material waste during spinning, thereby reducing production costs.

- Improve product aesthetics: High surface finish and processability make spinning finished products more beautiful, meeting the market’s demand for high-quality products.

- Enhance product competitiveness: With excellent performance and stable quality, spun aluminum wafer products are more competitive in the market.

Specification of Aluminium Circle for Spinning

| Product | Aluminium Circle for Spinning |

| temper | O、H12、H14、H16、H18、H24、H32、H36 |

| Thickness | 0.4mm-10mm |

| Diameter | 60mm-1200mm |

| Surface | The surface is bright and smooth, without defects such as white rust, oil spots, edge damage, etc. |

| Delivery Time | Within 30-45 days after receiving deposit |

| Packaging | Export standard packaging: wooden pallet + cardboard + steel bar fixed |

| Material | Using high-tech machinery and high-quality aluminum coils. |

| Size | Sizes can be produced according to customers’ colors/patterns. |

QC(Quality Control)

- Finished product inspection reports: We conduct thorough checks on every finished aluminum circles. After the detailed inspections, we issue a comprehensive report that gives you a clear picture of your product’s quality.

- Defective product handling records: When a product does not meet the mark, we do not just set it aside. We record the handling of defective products, including the reasons for non-conformity, handling methods and handling results, etc., to ensure that defective products are effectively controlled.

- Quality improvement records: According to the inspection results and customer feedback, record the situation and effect of quality improvement to continuously improve product quality and production efficiency.

Why Choose Us?

Choosing Chongqing Lanren Aluminium Co., Ltd is due to our unremitting pursuit of quality and innovation. As a leader in the industry, we have advanced production equipment and technical teams to ensure excellent product quality. Our company focuses on research and development. We’re constantly cooking up new products that hit the mark with what the market wants. That way, we can cater to all sorts of customer needs. At the same time, Honesty is our mantra in business. We offer high-quality services before, during, and after the sale. Our goal? To make sure you’re completely satisfied. Choosing us is to choose the double guarantee of quality and service, and create a better future together.

Packing&Delivery

1. We use customized wooden boxes and shockproof materials to ensure the safety of aluminum discs.

2. According to customer requirements, we can flexibly adjust the packaging direction.

3. We select the best logistics channels, and 20-foot containers are economical and efficient.

FAQ

Q1: Are you a trading company or a manufacturer?

A: We are a factory established in 2008, located in Nanping Industrial Park, Nanchuan District, Chongqing City, and are the leading aluminum cookware manufacturer in western China.

Q2: Can you send samples?

A: Absolutely! We can provide free samples, but freight is required.

Q3: What product information do I need to provide?

A: You need to provide the brand, width, thickness, coating, and tonnage you need to purchase.

Q4: How long does your delivery take?

A: Typically, our delivery time is 30-45 days. If the demand is extremely large or there are special circumstances, it may be delayed.

Q5: How long does your freight usually take?

Different countries have different times. Generally, it is 30-45 days.