Aluminum Foil for Transformer

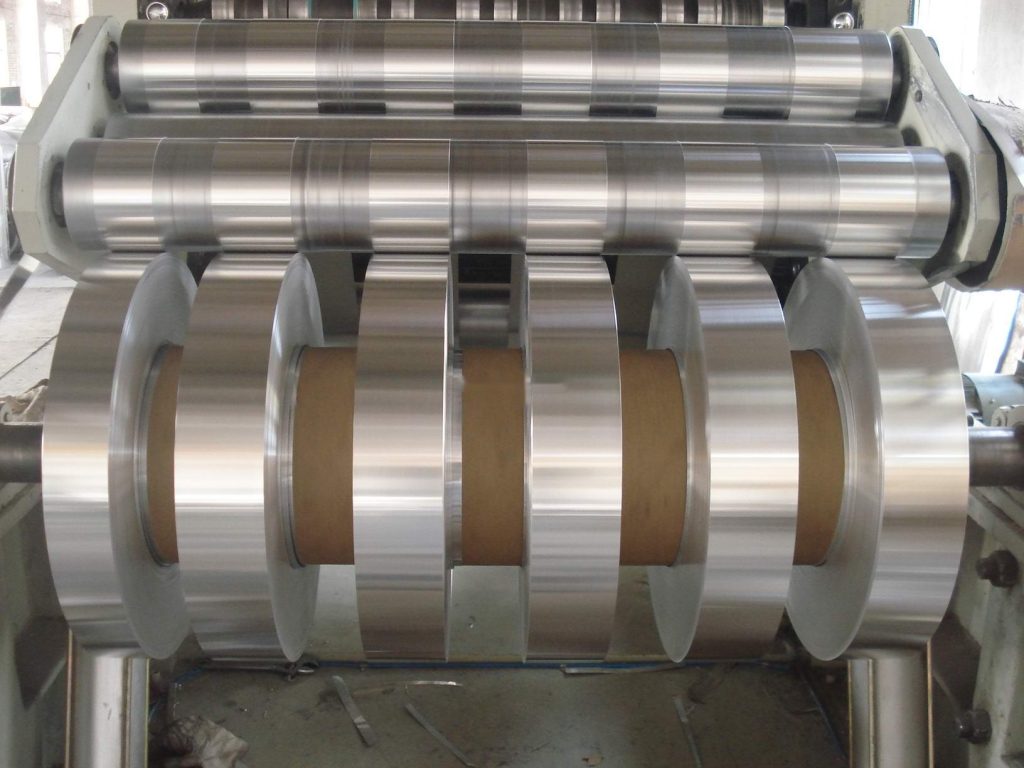

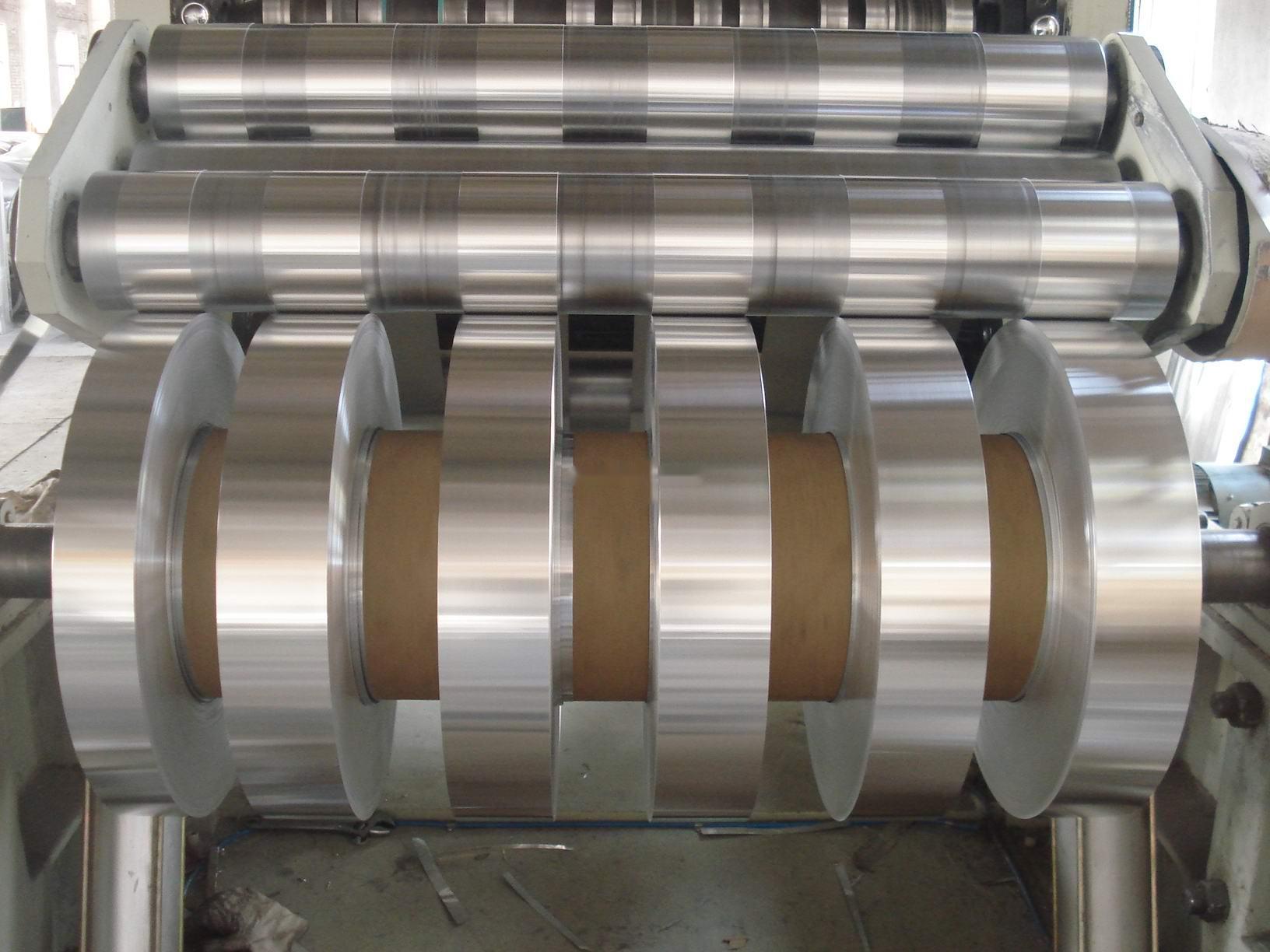

In transformers, aluminum foil is used for windings particularly in dry type transformers. Aluminum foil for transformer winding has excellent conductivity and purity with a soft texture, smooth surface, and no burrs. These can lower the weight and cost while still making sure that the transformer performs as it should.

At Lanren aluminum, the thickness of aluminum foil for transformers is used to make transformers typically ranges from 0.08-3mm and the width can vary from 20mm to 1650 mm. The aluminum foils are typically comprised of 1060 aluminum sheet and strips as raw materials. This sheet of aluminum contains more than 99.6 percent aluminum, and is known as the pure aluminum sheet. Contact us with your specific requirements.

Specification of

| Alloy | Aluminum (Al) MIN | Silicon (Si) MAX | Iron (Fe) MAX | Copper (Cu) MAX | Manganese (Mn) MAX | Magnesium (Mg) MAX | Zinc (Zn) MAX | Titanium (Ti) MAX | Other Elements (Total) MAX |

| 1050 | 99.50% | 0.25% | 0.40% | 0.05% | 0.05% | 0.05% | 0.05% | 0.03% | 0.03% |

| 1350 | 99.50% | 0.10% | 0.40% | 0.05% | 0.01% | 0.01% | 0.05% | 0.01% | 0.03% |

| 1060 | 99.60% | 0.25% | 0.35% | 0.05% | 0.03% | 0.03% | 0.05% | 0.03% | 0.03% |

| 1070 | 99.70% | 0.20% | 0.25% | 0.04% | 0.03% | 0.03% | 0.04% | 0.03% | 0.03% |

| Alloy | 1050, 1350, 1060, 1070 |

| Temper | O |

| Thickness | 0.08mm-3mm or as required |

| Width | 20mm-1650mm or as required |

| Quantity Tolerance | ±10% |

| Surface Treatment | The foil has a smooth surface, free from scratches and impurities. |

| Electrical Conductivity | 1050, >60%ACS |

| 1060, >61.5%ACS | |

| 1070, >62.7%ACS | |

| 1350, >62%ACS | |

| Applications | Transformer winding |

| MOQ | 5 Tons |

| Payment Terms | TT, 100% LC at sight |

| Packaging | Wooden Pallet/Wooden Case |

The main use of aluminum foil windings is the use of them for high-voltage windings and low-voltage windings for transformers.

In high-voltage windings, aluminium foil is wrapped using premium insulating foils and bonded with resin via vacuum casting to ensure the lowest discharge percentage and efficient thermal stress management for the transformer. Windings for low voltage are made with one sheet of copper foil or aluminum foil. The middle is insulated using glass fiber cloth coated with resin to give the transformer additional structural and electrical strength.

Advantages of

The major benefits of using aluminum foil for transformers are:

- Good thermal and electrical conductivity: Aluminium foil boasts excellent electrical conductivity. It effectively transfers current and also has a high thermal conductivity, helping to eliminate heat and help keep temperatures of transformers steady.

- Lightweight: compared with other conductors, like copper aluminum has less density, which means that Aluminum Foil for Transformer is lightweight, which can help lower the overall weight. It also makes it easier to transport and install.

- Corrosion resistance: The aluminum foil is resistant to corrosion and will work well inside the transformer for long periods of time.

- Cost-effectiveness: The cost of aluminum is usually less than copper and using aluminum foil as winding material for transformers will reduce the cost of production.

- Resource sustainability: The abundance of aluminum on the surface of Earth than copper, and is more accessible and therefore the use of aluminum foil improves to ensure sustainability of the resources.

FAQ

Q1: Are you a trading company or a manufacturer?

A: We are a factory established in 2008, located in Nanping Industrial Park, Nanchuan District, Chongqing, and we are a leading manufacturer of aluminum cookware in western China .

Q2: Can you send samples?

A: Yes, we can provide free samples, but we need to charge shipping fee.

Q3: what can you buy from us?

A: Aluminum Sheets, Aluminum Coils, Aluminum Strips, Aluminum Products

Q4: How long does your delivery time take?

A: Generally our delivery time is 30-45 days, if the demand is very large or there are special circumstances, it may be delayed.

Q5: Can I visit your factory?

A: Of course, we welcome customers from all over the world to visit our factory. However, some factories are not open to the public.