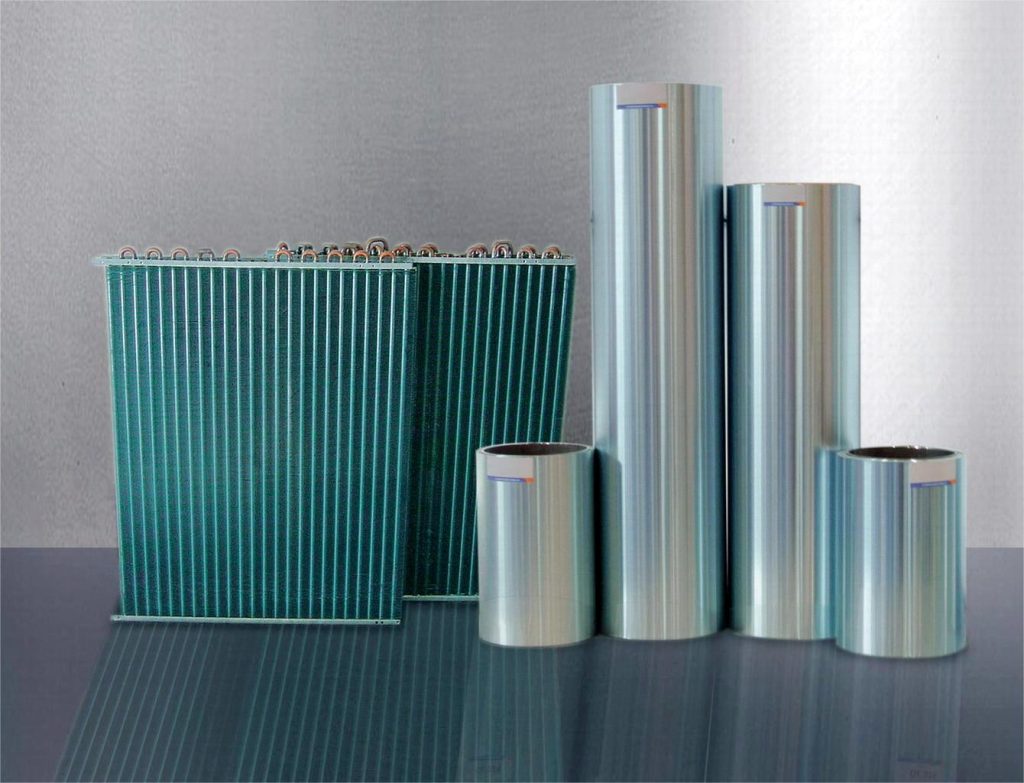

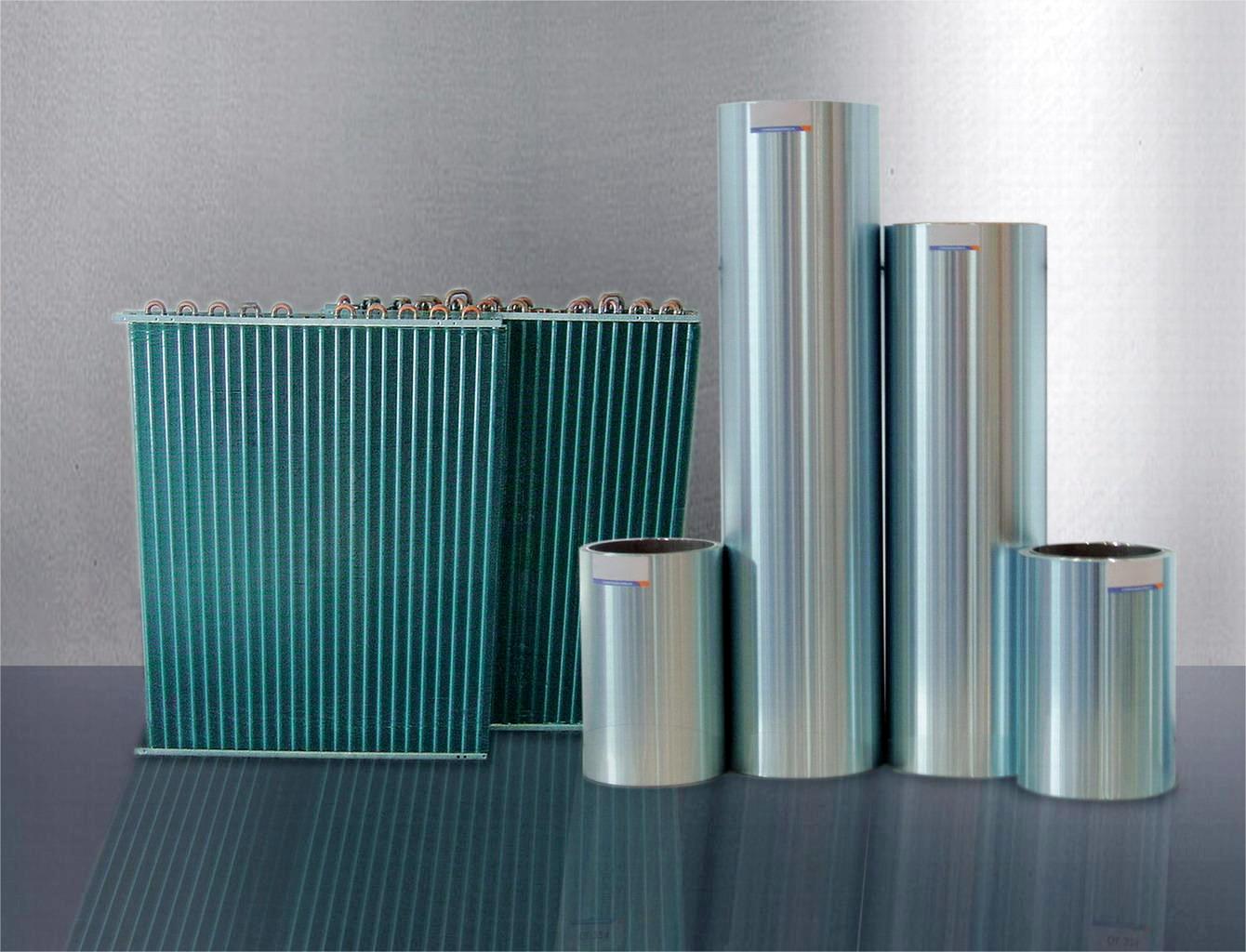

Aluminum Foil for Air Conditioner

Air Conditioner Aluminum Foil works as heat-conducting fins in the heat exchangers of air conditioners. Its superb ability to conduct heat permits the quick transfer of heat and cold, improving energy exchange, minimizing energy usage, and improving the heat/cooling exchange performance of the system.

Lanren, as a professional supplier, provides high-grade air conditioner aluminum foil, and bare and coated varieties. Coated types (hydrophilic for cooling, hydrophobic for heat exchange, anti-corrosion to prevent mold) are hydrophilic and hydrophobic for mold prevention of surface coatings. Reach out for more information.

Specification of Aluminum Foil for Air Conditioner

| Alloy | Temper | Thickness (mm) | Width (mm) |

| 1100, 1200, 3102, 8011 | H22, H24, H26 | 0.07-0.2 | 200-1650 |

Types of Aluminum Foil for Air Conditioner

Bare aluminum foil: This is an aluminum foil that is not treated with a surface, with good thermal conductivity, but a weak corrosion resistance. In certain applications uncoated aluminum foil is still utilized, particularly in situations that are cost-sensitive.

Coated aluminum foil: This aluminum foil has been specially treated on the surface and has better functionality than uncoated, such as enhanced corrosion resistance, hydrophilicity or hydrophobicity. Coated aluminum foil can increase the service life of air conditioners and improve heat exchange efficiency.

- Corrosion-resistant aluminum foil: This foil has an added layer of protection against harsh temperatures which works to improve the does improve the durability and poor air conditioner ventilation of air conditioners.

- Hydrophilic aluminum foil: Aluminum foil that has strong hydrophilicity which means that water which is in condensed form can flow freely and not gather between heat exchangers. This type of foil improves the heat exchange efficiency.

- Hydrophobic aluminum foil: Through increasing the angle of contact between heat exchangers and condensed waters the condensed water creates water droplets that are simple to slip off in order to accomplish the objective of removing condensed water from heat exchangers.

- Self-lubricating aluminum foil: There is no additional lubricating oil is required for punching. The surface film that has been treated prior to punching could serve as a lubricating element which makes production easier and reducing the cost.

- Anti-mildew aluminum foil: Mainly used in the air conditioners in order to avoid the formation of from forming mold on the exterior of heat exchangers, and keep the air quality good.

Advantages of Aluminum Foil for Air Conditioner

Compared with ordinary aluminum foil, special aluminum foil for air conditioners has the following unique performance advantages:

- Enhanced anti-corrosion and anti-mildew function: Special aluminum foil for air conditioners is generally treated with a hydrophilic treatment that enhances the anti-corrosion and anti-mildew capabilities of the material. This helps to prolong the performance and cleanliness of heat exchangers for air conditioners.

- Improved heat exchange efficiency: The hydrophilic treatment lets condensed water disperse quickly on the surface the aluminum foil, without forming droplets of water. This can lessen the blockage between heat exchanger plates and increase the efficiency of heat exchange generally by 5%.

- Reduced noise: Since the condensed liquid reduces the formation of droplets of water, the noise created by vibrations is decreased accordingly.

- Environmental protection characteristics: Special aluminum foil to protect air conditioners could stop the oxidation powder of an air conditioner from blowing into rooms to meet environmental protection standards and create better living conditions.

- Excellent formability and wear resistance: Special aluminum foil for air conditioners has good formability throughout the production process and is less prone to damage to the mould which makes it easier to create parts for heat exchangers with intricate forms.

- Resistance to stamping oil, solvents and heat: The improved properties of these materials make aluminum foil more durable in production and usage, and is able to withstand greater physical and thermal stress.

- Reduced airflow resistance: Due to its uniform distribution in condensed water resistance to airflow is decreased which further enhances efficiency of heat exchange.

These advantages make aluminum foil for air conditioners a more ideal material for air conditioner heat exchangers, helping to improve the overall performance and reliability of air conditioners.