Pure Aluminum Coil

Lanren’s Pure Aluminum Coils are made of pure aluminum that is processed through a variety of precision roll-making processes. Naturally formed and thick oxide film that is affixed to the exterior of the product offers excellent weather protection and resists corrosion. However, the low density of the material and quick heat conduction make it the ideal option to reduce the burden and elimination requirements. This aluminum coil is made to last and is pliable. It’s a vital product for all industries, from automotive and construction to packaging, electrical, and packaging providing solutions that are affordable and sustainable.

Description of Pure Aluminum Coil

- Lanren’s Pure Aluminum Coil is made of high-quality aluminum, and the purity ranges from 99.0 percent and 99.9 percent. The coil is then rolled through precisely controlled passing through the furnace and rolling to ensure that every inch has the same temperature and strength. The Aluminum surfaces are polished. This gives a seamless, smooth, and even appearance, which is crucial for any applications that require an elegant and sophisticated appearance.

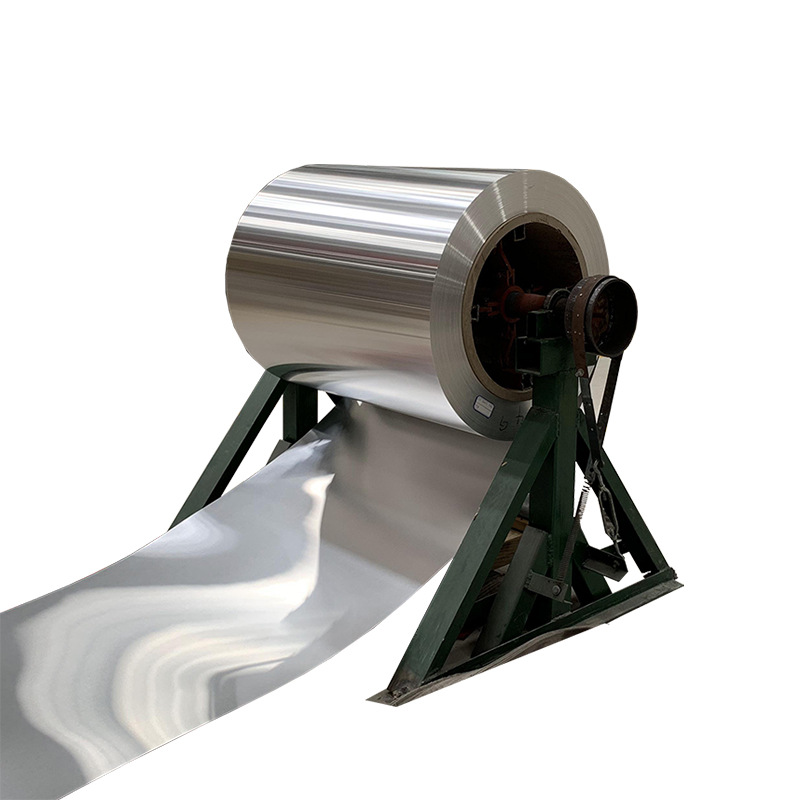

- The product is offered in various thicknesses, from thin sheets to sturdy gauges. This makes it flexible enough to be used in a variety of different ways. Length of coils can be adjusted depending on the requirements and offers a wide range of possibilities for use to. Available in various temper grades: H14 and H22. H14 in addition to H18 full-anneal, H22, as well as H24–the coil can be used to modify the strength-to-flex ratio your work demands.

- At Lanren, every coil is put through the wringer—tensile, bend, surface, the works—before the coil is sent, and we make sure to match every checkbox against ASTM, EN, and JIS checklists. This rigorousness is why our aluminum coils are placed in an area where it is unlikely to fail.

Specification of Pure Aluminum Coil

- Material Composition: 99.0% – 99.9% Pure Aluminum

- Temper Options: H14 (Half-Hard), H18 (Full-Hard), H22 (Quarter-Hard), H24 (Half-Hard), O (Annealed)

- Thickness Range: From 0.2mm to 6.0mm, accommodating various industrial requirements.

- Width Range: Available in widths ranging from 100mm to 2000mm, suitable for both narrow and wide applications.

- Coil ID (Inner Diameter): Options include 150mm, 200mm, 300mm, 400mm, and 500mm to fit various machinery and equipment setups.

- Surface Treatments:

- Mill Finish: For a smooth and reflective surface perfect for general use.

- Anodized: Enhances durability against corrosion as well as surface hardness, which is ideal for decorative as well as protective uses.

- Coated: Available with a variety of coatings to enhance specific properties like UV resistance, color, and durability.

Features of Pure Aluminum Coil

- Extraordinarily corrosion resistant: The nature that aluminum uses is an oxide coating that is extremely thin. The layer protects against corrosion and also corrosion. The coil is strong even in the most salubrious environments in the atmosphere, or in chemical facilities.

- Lightweight with High Strength: Aluminum’s low density means it’s a lot lighter than steel, and doesn’t compromise on durability. This makes it an ideal choice for areas where weight is an essential component, like aerospace and automotive manufacturing.

- Superior Thermal Conductivity: Aluminum is renowned for its ability to efficiently transfer heat and efficiently, making our pure aluminum coil a great choice for heat exchangers, radiators and a variety of other applications that require the management of thermal energy.

- Outstanding Electrical Conductivity: Pure aluminum coil is a superb conductor of electric current. This is the reason it is used extensively within the electric industry in order to create components like cables, transformers and conductors.

- Excellent Workability and Formability: The elastic nature of the material permits it to be bent and shaped into intricate configurations, without compromising the strength of the structure. This allows it to be employed in various fabrication methods.

- Eco-friendly and high recycling: Aluminum is 100% recyclable, and the recycling process requires less energy than creating new aluminum from ore that was mined. This improves sustainability by aligning it with green initiatives, while in turn, reducing the environmental footprint.

Applications of Pure Aluminum Coil

- HVAC Systems: The excellent thermal conductivity, as well as resistance to corrosion of pure aluminum makes it an indispensable component in condensers, heat exchangers, and evaporators, which are vital to the durability and effectiveness of HVAC systems.

- Electrical Industry:The electric conductivity in coils is extremely effective. Cable factories transform it into wire connectors and busbars. Transformer cables and windings depend on their capacity, weight, and very light as well as the resistance.

- Automotive Industry: In the automotive industry, the aluminum-free coil is used in body parts, heat shields, and other components that require a balance of light weight and strength. It is mainly responsible for improving performance in terms of emissions and fuel efficiency by decreasing the car’s weight.

- Architecture and Construction: Aluminum’s durability, corrosion resistance, and pliability make it suitable as a roofing material, for cladding as well as curtain wall construction. It’s also utilized for structural purposes where long-lasting and pleasing materials are needed.

- Packaging Industry: The non-toxic, lightweight, and corrosion-resistant nature of aluminum makes it an excellent choice for packaging, especially in the food and beverage industry where it is used for foil wraps, containers, and cans.

- Aerospace Industry: The aerospace industry greatly benefited from the lightweight and robust properties of pure aluminum coil that are used in the manufacturing of aircraft skins, fuselages, wings, and other parts of structural which require performance as well as durability.

- Marine Industry: Aluminum’s resistance to saltwater corrosion makes it ideal for marine applications, including shipbuilding, offshore platforms, and marine fittings.

Why Choose Us?

- Use high-quality alloys to ensure that our products are super durable.

- Offer custom sizes, colours, and surface finishes to meet whatever design you need.

- Resistant to to fading, rust and weather damage providing a long life of service.

- Surface finishes look fantastic and can be matched to any style exterior adding value to your property.

FQA

Q1: Are you a trading company or manufacturer?

A: We are a leading aluminum cookware manufacturer in western China.

Q2: How can we guarantee quality?

A: Always a pre-production sample before mass production; Always final Inspection before shipment.

Q3: What can you buy from us?

A: Aluminum Sheets, Aluminum Coils, Aluminum Strips, Aluminum Products.

Q4:Can I go to your factory to visit?

A: Of course, we welcome customers from all over the world to visit our factory. However, some of the plants are not open to the public.

Q5:How long does your delivery time take?

A: In general, our delivery time is within 30-45 days and may be delayed if the demand is extremely large or special circumstances occur.