All articles

What Types of Aluminum Alloys can Be Anodized?

If you work with aluminum for any length of time, this is one of the questions that always comes up: Can this alloy be anodized? The short answer is: Yes, most…

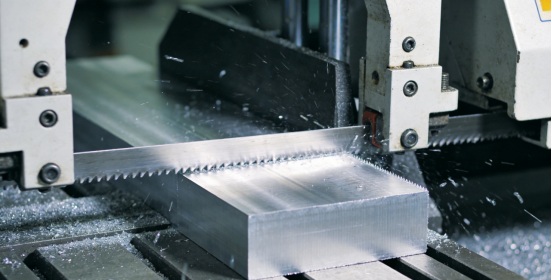

How to Cut Aluminum Sheet Easily & Precisely?

Cutting aluminum sheet may seem straightforward, but getting a nice, pinpoint, and clean cut can be trickier than you think. Many individuals end up with bent edges, ragged edges metal,…

Is it Safe to Use Aluminum Packaging Foil for Food Storage?

The use of aluminium packaging foil in the kitchen has been prevalent for many years. It is a versatile product that is utilised in different ways in the home and…

Understanding Differences Between Standard and Heavy Duty Aluminum Foil

During your shopping trip to the supermarket, you might come across a wall of shiny packages, each claiming to keep your food fresh and your pans clean. But the truth…

How to Store Aluminium Circles to Avoid Oxidation?

Aluminium circles find usage in a variety of industries like cookware, metal stamping, deep drawing, and spinning, where surface quality is the processing and the final product appearance’s critical factor. Oxidation…

Why aluminum coils beat steel for everyday builds? 5 Core Advantages Explained

In the case of aluminum coils and steel, they are the two materials that can enhance or ruin the efficiency, cost, and the long-term performance of everyday construction projects at…

Choosing a Reliable Aluminium Cookware Manufacturer: B2B Buyer Should Know

The failure to source aluminium cookware usually does not originate from the quality of the product, but rather from supplier selection. A lot of B2B purchasers have to deal with…

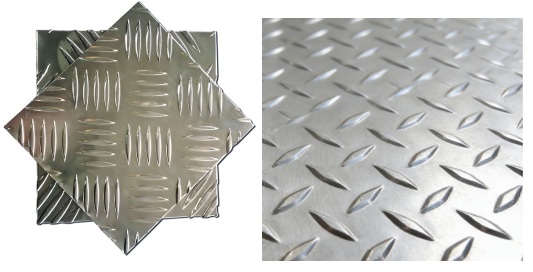

Which to Choose for Anti-Slip Applications? Aluminum Chequered Plate or Aluminum Diamond Plate

When buying metal plates to use on ramps, floors or walkways, as well as on vehicle surfaces, many people have this issue: “I require an aluminum plate with balanced anti-slip…

What are the Types of Aluminium Coating & Their Applications?

Why Coating on Aluminium? With many years of experience in the manufacturing of aluminium products, I can affirm that even though there is natural corrosion resistance from the material, very…

Are Aluminum Pans Safe for Cooking?

Between the outdoor and indoor cooking industry, aluminum pans has dominated the cookware industry for decades and is usually the most popular choice by consumers for their weight, and fast…

5 Key Factors That Affect the Price of Aluminium Circles

As a seasoned manufacturer in the aluminium industry, we have often heard one straightforward question from our clients: “What’s the aluminium circle price?” The simplicity of this question is just skin-deep…

Is Aluminium Foil Good for Food Packaging?

According to the market report, the global aluminum foil packaging market was valued at approximately US$14.54 billion in 2024 and is projected to grow at a compound annual growth rate (CAGR) of about 5.45% through 2032…