How the Thickness of Aircraft Aluminum Sheets Affects Their Performance?

Each of its parts conditions the performance of an airplane, and the aluminum sheets that form its structure are no exception. The seemingly straightforward characteristic of sheet thickness is, however, a very sophisticated parameter that conditions everything from the aircraft’s structural stability to its operational efficiency.

This paper, based on my own experience in the manufacture of aircraft aluminum sheets, will examine the complex relationship between sheet thickness and aircraft performance. We will examine how thickness variations influence such important characteristics as strength, weight, fatigue life, and manufacturing and cost feasibility.

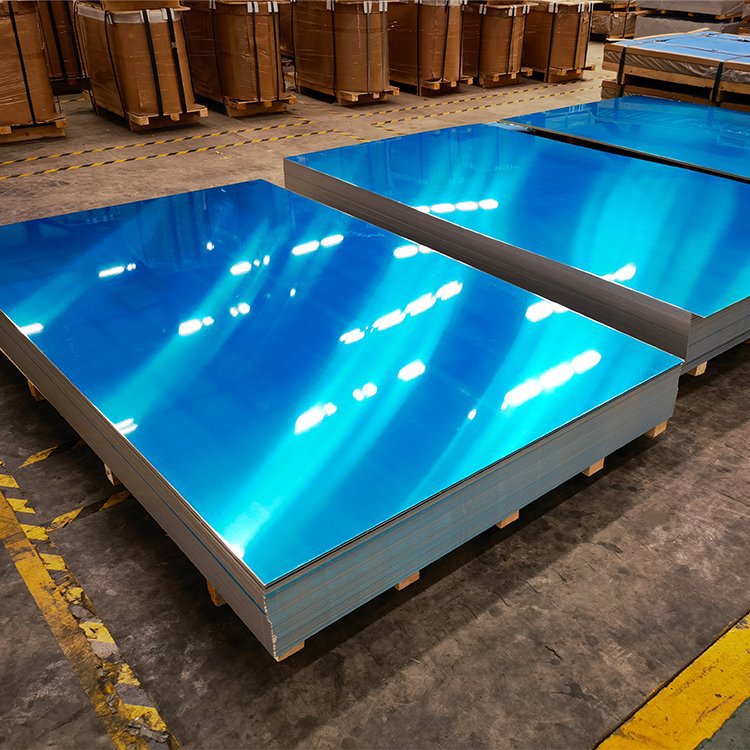

Properties of Aircraft Aluminum Sheets

Before examining thickness, it’s crucial to understand the fundamental material characteristics of aircraft aluminum sheets. These are not just any aluminum, but highly engineered alloys designed for specific aerospace applications. The choice of alloy significantly influences the base properties that thickness then modulates.

Material Characteristics among different alloys

Aircraft aluminum is typically categorized into series based on their primary alloying elements, each offering a unique balance of properties:

| Alloy Series | Primary Alloying Element(s) | Key Characteristics | Typical Applications (Examples) | Representative Alloy (Temper) | Typical Tensile Strength | Typical Yield Strength |

| 2xxx | Copper (Cu) | High strength, excellent fatigue resistance, good toughness. Lower corrosion resistance without cladding. | Fuselage skins, wing tension members, structural frames. | 2024-T3 | 469 MPa (68 ksi) | 324 MPa (47 ksi) |

| 7xxx | Zinc (Zn), Magnesium (Mg), Copper (Cu) | Highest strength-to-weight ratio among aluminum alloys. Good fracture toughness. Lower ductility and sometimes lower corrosion resistance than other series. | Wing spars, landing gear components, bulkheads, highly stressed structural parts. | 7075-T6 | 572 MPa (83 ksi) | 503 MPa (73 ksi) |

| 6xxx | Magnesium (Mg), Silicon (Si) | Good strength, excellent corrosion resistance, highly weldable, good formability. | Less critical structural components, support structures, general fabrication, tubing. | 6061-T6 | 276 MPa (40 ksi) | 241 MPa (35 ksi) |

| 5xxx | Magnesium (Mg) | Excellent corrosion resistance (especially in marine environments), good formability, moderate strength. | Fuel tanks, hydraulic lines, non-structural components, pressure vessels. | 5052-H32 | 228 MPa (33 ksi) | 159 MPa (23 ksi) |

How Thickness Affects Performance?

The chosen alloy determines the general characteristics of the aluminum sheet. But it is the thickness the sheet is which translates these characteristics into actual performance in an aircraft component. The smallest variation can bring enormous differences in how material performs under load, over the years, and in the economics of aircraft manufacturing and operation.

Strength and Stiffness

The most direct relationship of thickness to function is with strength and stiffness. The thicker the sheet, the larger the cross-sectional area that exists and thus the larger the loads the sheet can support before yielding or fracture failure.

- Tensile Strength and Yield Strength: Thicker sections generally result in higher ultimate tensile strength and yield strength of the component for a given alloy. The explanation for this is the increased volume of material available to carry the load. For example, a sheet of 7075-T6 alloy measuring 3.18mm (0.125 inch) in thickness would be of higher total load-carrying capacity than a similar sheet measuring 1.27mm (0.050 inch) in thickness. In major structural members like wing spars that undergo gigantic bending loads while in flight, insufficient thickness would lead to immediate failure of the structure.

- Stiffness and Rigidity: Besides breaking strength, thickness plays an important role in determining stiffness. A thicker sheet is more resistant to bending, buckling, and deformation by loads. This is necessary to obtain aerodynamic shapes and realize steady flight. Consider a wing skin, for instance: it may too easily flex during aerodynamic loading if too thin, deforming the wing shape and negatively impacting lift and drag. This would be a phenomenon known as “flutter,” an undesirable aeroelastic instability. The cross-sectional moment of inertia is proportional to the cube of thickness, so that a slight increase in thickness produces a large increase in stiffness.

While greater thickness always provides more strength and stiffness, there are diminishing returns. Eventually, other factors like buckling instability in thin-walled structures or the fundamental strength limits of the alloy itself become the limiting factors rather than pure tensile strength.

Performance vs. Efficiency

The quest for aircraft performance is always exchanged for the need for efficiency, and sheet thickness is right in the middle of this bargain. Any gram added to an aircraft’s structure immediately translates into either reduced payload capacity or increased fuel burn.

- Weight Penalty: Additional material, thus a thicker sheet, straightaway contributes to the empty weight of the aircraft. For commercial airliners, every kilogram saved can translate into thousands of dollars in fuel savings over the aircraft’s lifetime, or allow for an additional passenger or cargo. For military aircraft, reduced weight can mean increased range, speed, or weapons. For instance, if a designer called for a 2.0 mm thickness sheet instead of a 1.0 mm thickness sheet on a non-critical panel, the weight would double, an unwanted penalty.

- Fuel Efficiency and Operating Costs: The relationship is straightforward: heavier aircraft require more thrust to achieve and maintain flight, which means more fuel burn. This has a direct impact on airline operating costs and the environmental impact. Manufacturers thoroughly analyze load paths and stress distributions using advanced simulation tools to establish the absolute minimum thickness of each part, minimizing weight without compromising safety. Optimization is a continuing challenge, pushing the creation of new manufacturing techniques that can create desired properties with less material.

Fatigue and Durability Considerations

Air structures are subjected to millions of load cycles within their operational lifetime—take-offs, landings, gusts, pressurization cycles. Cyclic loading causes material fatigue wherein cracks begin and propagate even at stresses way below the material yield strength. Thickness plays a multi-dimensional role in managing fatigue and long-term endurance.

- Fatigue Life: In some cases, thicker sections can be more fatigue-resistant by virtue of spreading stresses over a larger volume and eliminating local concentrations of stress. It is not always inversely related. Thicker sections can be more prone to initiation of cracks in some cases due to residual stresses from processing, or simply having a larger volume where defects could exist. The key point of interest is most often the range of stress the material sees. A heavier section, being rigid, might endure less strains and thus a lower stress range for the same load application and thus enhance fatigue life.

- Damage Tolerance: Modern aircraft design incorporates “damage tolerance” concepts, i.e., even after crack initiation, the structure must have the ability to withstand it safely until detection and repair. Thick sheets tend to have more reserve strength and a longer “crack growth path,” so there is more time for detection before catastrophic failure. This is especially valuable in areas like the fuselage skin, where pressurization cycles are repeated again and again. A small crack can form here, but a thick enough skin will allow it to grow slowly enough to be found during routine inspections. For example, a fuselage skin clad aluminum sheet of 2024-T3 typically has a specific thickness (e.g., 0.040 to 0.080 inches) to balance fatigue resistance and damage tolerance against weight.

- Corrosion Resistance: Thickness has no direct bearing on corrosion resistance (alloy content and surface treatment do), but an over-thick sheet provides more sacrificial material before corrosion makes a meaningful contribution to weakening structural integrity. In saltwater applications such as coastal operations or humid climates, a higher gauge might offer more of a cushion against material loss in the long term.

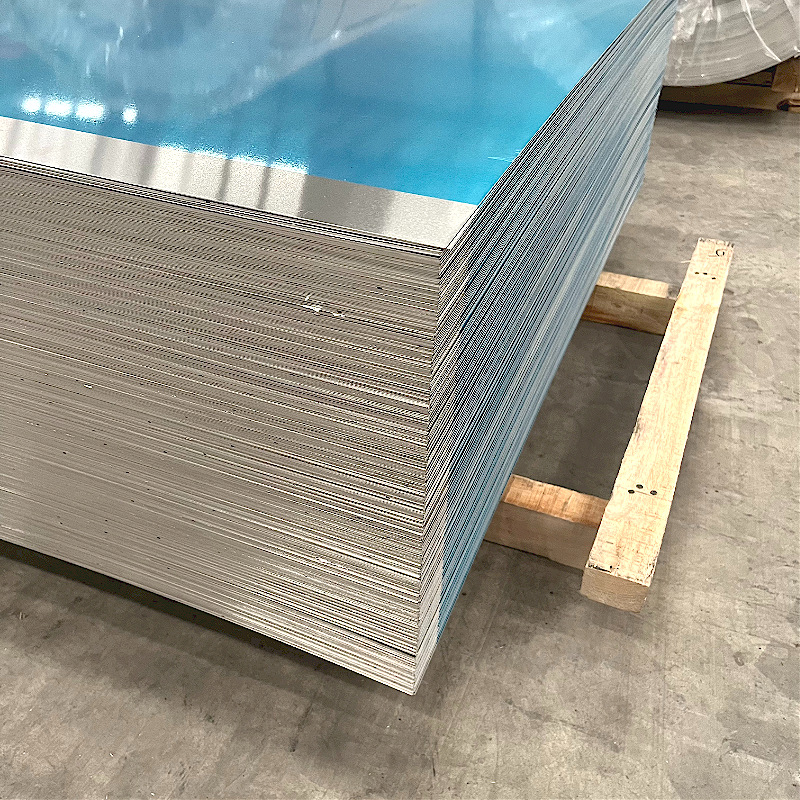

Manufacturing and Cost Implications

The thickness of the aluminum sheets for aircraft has significant practical implications on the cost and manufacturing process. Such factors are taken seriously into consideration while designing and procuring.

- Manufacturing Processes:

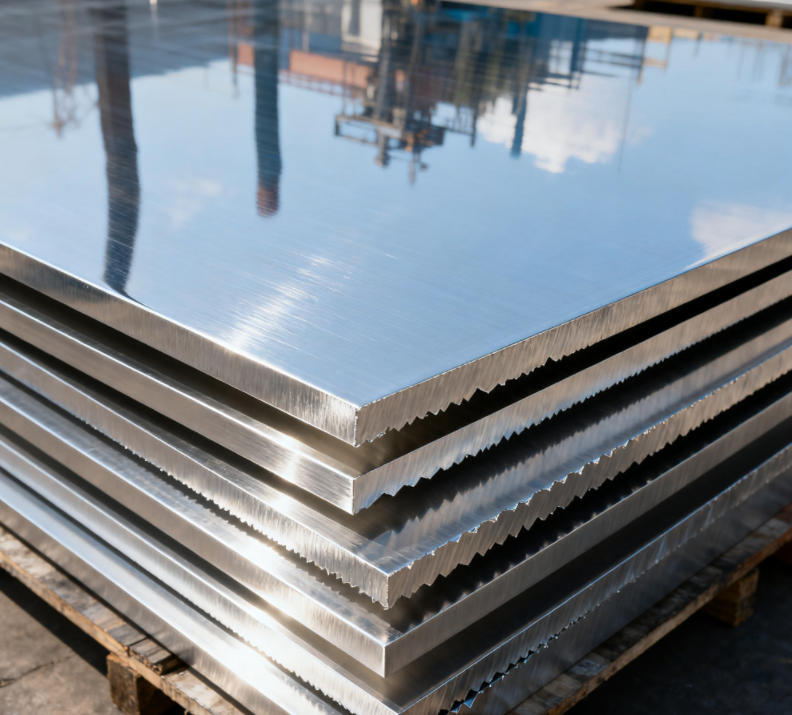

- Forming and Shaping: Thicker sheets are harder to form and shape into the complex aerodynamic curves. They require more powerful presses, greater bend radii to prevent cracking, and perhaps more sophisticated techniques like stretch forming. This increases tooling cost and processing time. For example, forming a tight radius on a 6.35 mm (0.25 inch) thick plate of 7075-T6 requires significantly more force and specialized tooling compared to forming an equivalent radius on a 1.0 mm (0.040 inch) sheet.

- Machining and Fastening: Drilling fastener or rivet holes and machining cutouts in thicker sheets takes time and wears out the tools faster. This influences production efficiency as well as tooling expense. Thicker plates, up to 200mm for parts like the C919 wing box, are typically directly milled from solid blocks and require massive machining capacity.

2. Material Cost: Simply put, the thicker sheets contain more material, which directly translates to a higher raw material cost per unit area. Given the vast quantities of aluminum used in an aircraft, even small increments in thickness in multiple components can significantly contribute to the cost of materials.

3. Handling and Logistics: Thicker, heavier sheets are harder to ship, store, and handle in the factory. This influences material handling equipment, safety protocols, and overall logistics costs.

The choice of thickness is thus a careful dance between engineering necessity and economic viability, ensuring that the aircraft is safe and performs optimally while remaining commercially competitive.

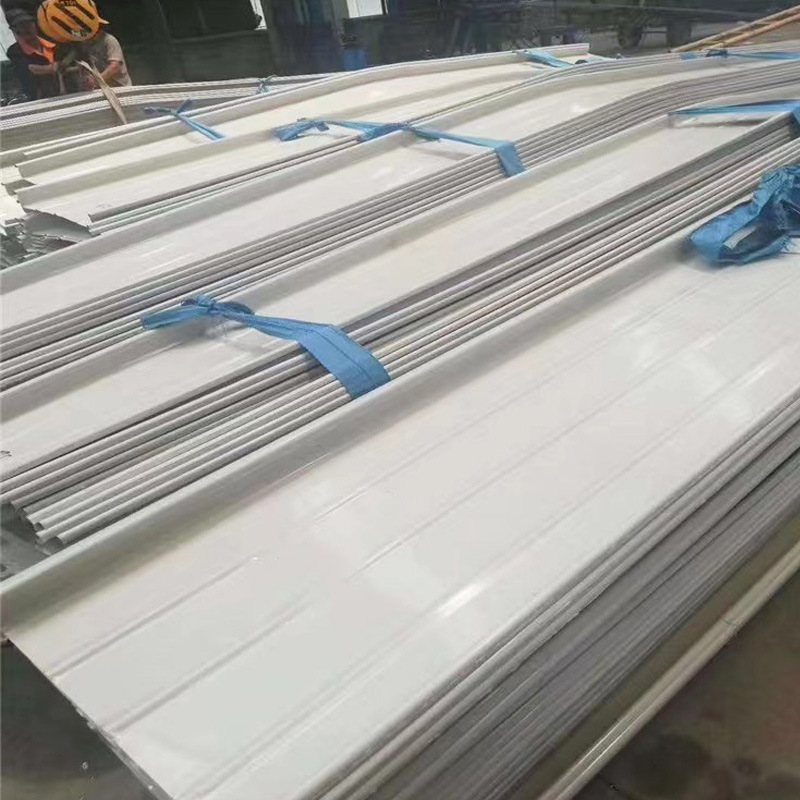

Thickness Selection for Different Aircraft Parts

The uniformity of an aircraft’s external appearance belies the significant variations in aluminum sheet thickness used throughout its structure. Each component faces unique stresses and operational demands, dictating a tailored approach to material selection and thickness.

Application-Specific Thickness Requirements

Engineers use sophisticated tools like Finite Element Analysis (FEA) to simulate aerodynamic loads, internal pressures, and structural vibrations, enabling them to optimize thickness for every square inch of the aircraft. This meticulous process ensures that each part is “just strong enough” – no more, no less – to meet performance and safety criteria. Please consider the following examples:

| Aircraft Part / Component | Typical Thickness Range (Metric) | Typical Thickness Range (Imperial) | Common Aluminum Alloys | Key Performance Drivers for Thickness Selection |

| Fuselage Skin | 1.0 mm – 2.5 mm | 0.040 in – 0.100 in | 2024-T3 (clad) | Cyclic pressurization, fatigue resistance, damage tolerance, bending/torsional loads. Thicker around windows and doors. |

| Wing Skins | 1.5 mm – 25 mm+ | 0.060 in – 1.0 in+ | 7075-T6, 7050-T7451, 2024-T3 | High bending moments (thicker at root), lift and drag forces, stiffness to prevent flutter, fatigue. |

| Ribs & Spars | 1.5 mm – 200 mm | 0.060 in – ~8 in | 7075-T6, 7050-T7451 | Resisting buckling, transferring loads, structural integrity of wing/fuselage framework. (Spars often machined from very thick plate). |

| Empennage (Tail Section) Skins & Structures | 1.0 mm – 4.0 mm | 0.040 in – 0.160 in | 2024-T3, 7075-T6 | Aerodynamic loads, vibrations, balancing stiffness and weight. |

| Access Panels & Fairings | 0.5 mm – 1.0 mm | 0.020 in – 0.040 in | 6061-T6, 5052-H32 | Lightweight, aerodynamic smoothness, ease of fabrication, minimal structural loads. |

Aircraft design requires precise thickness tailoring to achieve the desired performance for each component. For example, thin fuselage panels ensure a lightweight structure, while thick aluminum plates are critical for areas subjected to intense forces.

Final Thoughts

By understanding the nuanced relationship between thickness and performance, manufacturers and engineers can create designs that meet the stringent demands of the aerospace industry. As technology advances, innovations in materials and manufacturing are likely to further refine the role of thickness in aircraft design.

Related Products