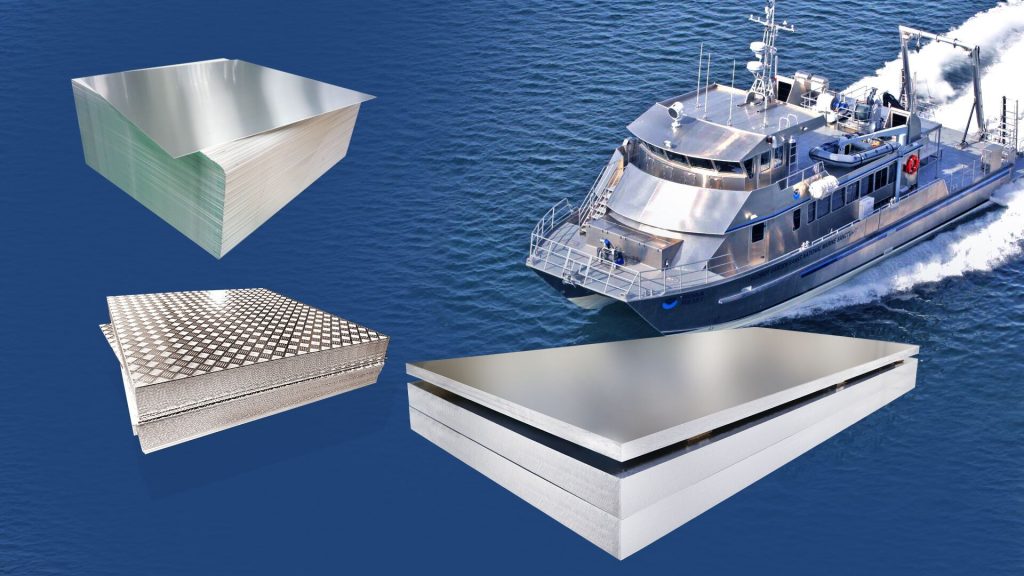

5052 Aluminium Plate

- Length: 500MM – 10000MM or as required

- Standard: ASTM B209, ASTM B947, ASTM B548

- Surface: Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc.

- Lead Time: Within 7-15 days after receiving the deposit

- Payment Terms: TT, 100% LC, Western Union

5052 aluminium plate is an alloy of aluminium and magnesium 5052 which is known for its excellent corrosion resistance and medium-strength, making it ideal for marine environments. The alloy is also known for being ductile which helps it bend, deep draw, and spin easily. Both hot and cold working techniques can be used.

5052 plate can also be easily machined, making it ideal for CNC and precision cutting. If softening is needed, 5052 can be softened with an annealing process of 775°F. 5052 is known for having a good balance of corrosion resistance, formability, and strength.

Specifications of 5052 Aluminium Plate

| Number | 5052 |

| Brand Name | Lanren |

| Temper | H12, H14, H16, H18, H22, h24, h26, H28, H36, H38, etc. |

| Thickness | 0.2MM – 300MM or customer required |

| Width | 500MM – 2500MM, according to customer’s required |

| Standard | ASTM B209, ASTM B947, ASTM B548 |

| Lead Time | Within 7-15 days after receiving deposit |

| MOQ | 1 Ton, please contact us for special needs. |

| Tolerance | ±1% |

| Packaging | Export standard packaging: wooden pallet + cardboard + steel bar fixed |

| OEM service | Perforated, Cutting special size, Doing flatness, Surface treatment,etc |

5052 Aluminium Plate Chemical Properties

| Element | Al | Cr | Cu | Fe | Mg | Mn | Si | Zn |

| 5052(min) | 95.7% | 0.15% | – | – | 2.2% | – | – | – |

| 5052(max) | 97.7% | 0.25% | 0.1% | 0.4% | 2.8% | 0.1% | 0.25% | 0.1% |

5052 Aluminium Plate Mechanical Properties

| Property | Metric |

| Hardness, Brinell | 47 |

| Poisson’s Ratio | 0.33 |

| Melting Point | 607 – 649 °C |

| Electrical Resistivity | 4.99e-006 ohm-cm |

| Modulus of Elasticity | 70.3 GPa |

| Specific Heat | 0.88 J/g-°C |

Advantages of 5052 Aluminium Plate

From the viewpoint of production, our manufacturing offers several valuable features for the 5052 Aluminum Plate:

- Quality Assurance: The production processes of our 5052 Aluminium Plates follow rigorous quality control processes, granting compliance with the standards (for example, ASTM B209), which certifies the trustworthiness and functionality of our products.

- Mechanical Properties: The 5052 plates possess high tensile and fatigue strength, excellent plasticity, and other favorable mechanical properties, which are a versatile asset for many engineering processes and are further improved by cold working.

- Chemical Composition: 5052 plates are manufactured to outperform in resisting corrosion, especially in marine environments, which makes them useful for shipbuilding and marine structures because of the ideal composition of aluminum, magnesium, and chromium.

- Customization Capabilities: Our manufacturing facility accommodates a large variety of customer needs, providing upto alteration of an order’s specific size, thickness, and even surface treatment for different project requirements.

- Global Supply Network: With a strong supply chain for 5052 Aluminum Plates, we are able to supply for seamless order installation for customers situated at any part of the globe.

Reliability, as stated before, is our number one priority. Not only that, but our manufacturing plant is fully optimized to ensure that there is no lack of zeal or enthusiasm. This proves that we do care, and thus enables us to lead in innovations in the Aluminum and manufacturing industry.

Application of 5052 Aluminium Plate

- Marine Applications: Also called “marine grade aluminum,” 5052 aluminum is extensively applied in ship construction and boat hulls because of its high resistance to saltwater corrosion.

- Automotive Industry: Its useful in automotive manufacturing for fuel tanks, hydraulic pipes, and body panels because of the alloys strength and formability.

- Aerospace Industry: Its unique lightweight characteristics, along with its strength, corrosion resistance, and durability make the alloy ideal for aircraft structural components.

- Electronics and Electrical Appliances: Aluminum panels and parts of chassis for electronics that need to be lightweight yet conduct electricity well and be free from corrosion deploy the alloy.

- Pressure Vessels and Chemical Equipment: These plates are perfect for use in pressure vessels and machinery which are prone to chemical reactions because of their strength and durability.

- General Engineering and Manufacturing: The alloy is useful in making parts that need to be moderately strong yet still have good workability.

- Hardware and Fasteners: The alloy is perfect for use in the manufacture of fasteners and rivets made from special automotive grade aluminum alloys due to their strength and ease of machining.

Why Choose Lanren Aluminium as Your Supplier?

Lanren Aluminum is among the direct providers of 5052 aluminum plates, which means that the cost is extremely low and the source is reliable without the intervention of any agents.

Strict quality control and compliance with international standards are the two measures taken by Lanren Aluminum to ensure the most consistent quality. Besides, the factory guarantees the fastest and most secure supply of orders due to its operation on a large scale. Simultaneously, cost efficiency is driven by a narrow gauge of process and a high level of quality at the same time.

We are highly skilled in technical matters, highly experienced with global exports, very open about pricing, while still being able to offer customization support that is highly needed in high-volume production. Our aluminum plate offers are very much in favor of the customer.