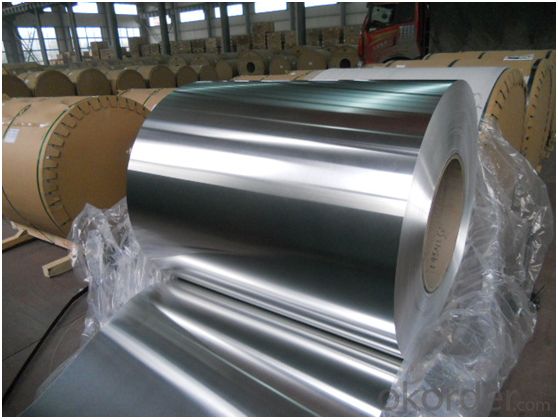

Why aluminum coils beat steel for everyday builds? 5 Core Advantages Explained

In the case of aluminum coils and steel, they are the two materials that can enhance or ruin the efficiency, cost, and the long-term performance of everyday construction projects at the very beginning of the selection process. Although steel has been the usual go-to material, aluminum coils have become the superior choice for most daily constructions due to their outstanding combination of performance, sustainability, and usability. After the jump, we will elaborate on the five main benefits that make aluminum coils the preferred option for modern daily construction.

Advantage 1: Lightweight Design

One of the most important advantages of aluminum coils is their remarkable strength-to-weight ratio. Despite aluminum coils being composed of only 2.7g/cm³, which is just one-third of the density of 7.8g/cm³ for steel, they provide considerable strength without increasing the volume of the material. For instance, aluminum coils from 5052 alloy can still support the loading of 38 N/mm² even at a thickness of only 0.2mm; thus, they are perfect for applications that require strong and at the same time, thin materials such as smiling rain gutters and lightweight curtain wall panels.

The lightness of the material results in physical advantages that are noticeable in the construction of buildings: no necessity for heavy lifting machines; it is possible for a single person to install the materials; and there is a decrease in the stress that is put on the structure of the building as a whole. The costs associated with transportation are also reduced significantly: the shipping of an aluminum-coil gutter of the same size is more than 30% cheaper than that of a steel gutter because it requires fewer trips or smaller vehicles.

The following table lists the comparison of the weight and logistical advantages of aluminum and steel coils for a normal 100m gutter project:

| Aspect | Aluminum Coil Gutter | Steel Coil Gutter |

| Material Density | 2.7g/cm³ | 7.8g/cm³ |

| Total Weight (100m) | ~120kg | ~350kg |

| Installation Requirement | 1-2 workers | 3-4 workers + crane |

| Transportation Cost | $50-$80 | $150-$200 |

Advantage 2: Superior Corrosion Resistance

Moisture, salt spray, and acid rain are some of the harsh conditions that everyday outdoor constructions—like exterior cladding or gutters in coastal areas—are constantly subjected to. Without galvanization, steel usually hasty succumb to rust in a short period of 3-5 years and then it requires constant maintenance (re-coating or even replacement) which adds both time and cost. On the other hand, the natural property of aluminum to resist corrosion saves it the trouble of being maintained at all.The interaction with the air gives aluminum a dense oxide film which measures from 5 to 10 micrometers and functions as a built-in protective layer. Moreover, the resistance is further intensified when the alloy is coated with PE or PVDF (widely used in construction)—the lifetime of aluminum coil components outdoors is over 15 years even in the most severe conditions.

The long-term cost savings are quite impressive: steel has to be maintained every year at a cost of about $1.10/㎡ for galvanization or repainting, while aluminum coils are virtually maintenance-free. Thus, over a 10-year period, total maintenance costs are brought down by more than 60%.

Advantage 3: Exceptional Workability

Almost every construction project requires that the so-called “small-batch, multi-specification” components—curved gutters, and custom-shaped curtain walls panels among them—and the application of aluminum coils is great at these varying needs. Their high ductility (particularly in alloys like 3003 and 5052) enables them to be easily processed by cold rolling, stamping, and bending without cracking, even for very complex shapes.

Moreover, aluminum coils provide the highest possible specification flexibility; widths can be ordered in 20mm up to 2650mm increments and 0.2mm to 6.0mm thick—ideal for everything from thin decorative trims to thicker structural supports. Steel, on the other hand, has to go through more complicated processes because of its high hardness; thus, forming a complex curved gutter from steel costs 40% more than from aluminum.

Surface treatment is another area where aluminum coils prevail: spraying, brushing, and anodizing are all possible with aluminum coils, thus allowing for the creation of aesthetic requirements (e.g., wood grain or stone textures), which in turn leads to durability. However, with steel, one has to apply additional layers to produce similar visual effects, which ultimately raises both the cost and the time spent on processing.

Advantage 4: Sustainability

The consideration of the environment has become a major factor in the construction of the modern coils of aluminum which have been classified as an eco-friendly option. While steel can be recycled, aluminum is 100% recyclable and the recycling of the alumina coils needs only 5% of the energy to produce the primary aluminum (which is 2-3 times for steel recycling and thus more energy consuming).

Such sustainability is seen as a real-world positive impact: the use of recycled aluminum coils on a residential rain gutter project can result in a decrease in carbon emissions of about 80 tons, when compared with the use of new steel coils. The fact that aluminum is light also helps to save energy indirectly. Transporting lighter components means fewer trips with fuel consumption, and in the case of buildings, the decreased structural load results in less demand for heating and cooling which is the long-term energy use.

Advantage 5: Better Cost-Effectiveness

Aluminum coils, although having a unit price 15-20% higher than ordinary steel coils, still possess a total cost of ownership (TCO) that is considerably lower for anybody’s daily builds. Initially, after including transportation and installation as shown in the above table, the cost is less than 5%.

During a 10-year period, TCO of aluminum coil parts (for example, gutters or curtain wall panels) is 25-30% less than that of steel. This is due to three reasons namely not having any maintenance costs, longer service life (15+ years vs. 5-10 years for steel), and higher resale/recycling value. For buildings with a lifespan over 5 years, which is the case for most daily constructions, aluminum coils are the more cost-effective option.

Conclusion

Gutters, curtain walls or small structural parts whatever you are making, reliable and efficient aluminum coils will allow you to complete your projects on time and within the financial limit. When it comes to cutting-edge, eco-friendly construction, aluminum coils are no longer a second-best option to steel but rather a better one.

For best quality, customized specifications, and reliable support that will enhance the quality of your normal construction work, turn to Lanren Aluminum’s aluminum coils—cooperate with us in realizing your construction objectives with materials that are trustworthy.

luminium cookware needs, see if a long-term manufacturing partnership is a viable option.

Related Products