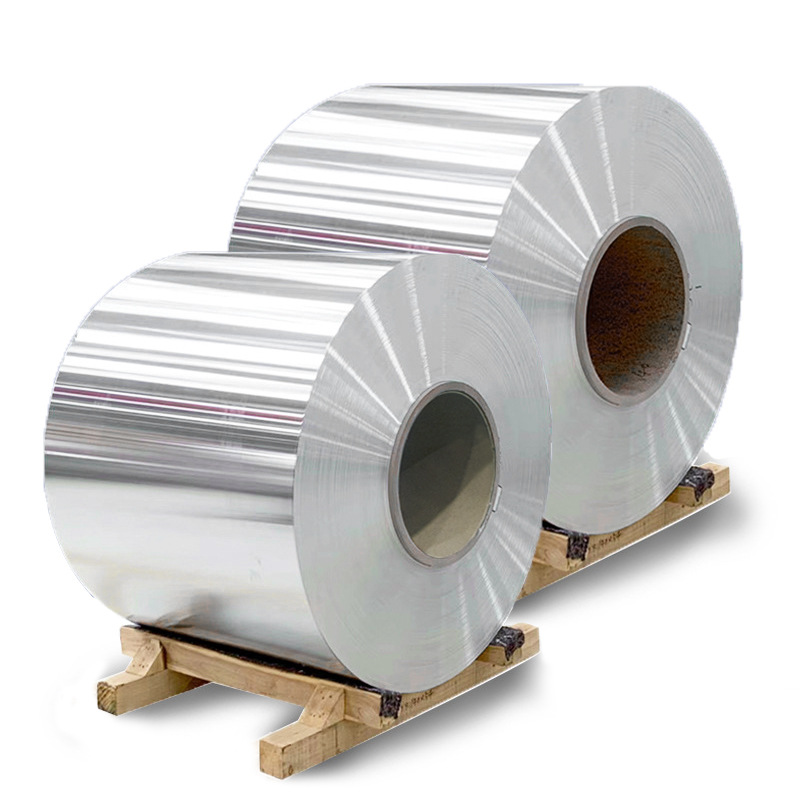

5052 Aluminum Coil

5052 aluminum coil are preferred in a wide range of applications due to their superior durability, strength, corrosion resistance, and formability. The alloy is particularly suitable for use in marine environments due to its superior resistance to seawater corrosion.

Its moderate strength and excellent performance make it ideal to fabricate components that need durability as well as ease to manufacture. It can be used for construction transport, consumer products, Lanren 5052 aluminum coil is a durable and flexible solution.

Specifications of 5052 Aluminum Coil

| Specification | Value |

| Temper | O, H32, H34, H36, H38, H39 |

| Thickness | 0.004″ to 1.000″ |

| Width | 16″ to 60″ |

| Length | Up to 10,000 feet |

| Yield Strength | 16,000 to 18,000 psi |

| Tensile Strength | 25,000 to 27,000 psi |

| Elongation | 30-35% |

| Hardness | 70-90 Brinell |

Chemical Composition of 5052 Aluminum Coil

| Element | Aluminum (Al) | Magnesium (Mg) | Manganese (Mn) | Chromium (Cr) | Silicon (Si) | Copper (Cu) | Zinc (Zn) | Iron (Fe) | Other Elements |

| Weight Percentage | 97.6-99.0 | 2.5-4.5 | 0.10-0.25 | 0.10-0.25 | 0.10 max | 0.10 max | 0.10 max | 0.10 max | 0.10 max |

Advantages of 5052 Aluminum Coil

5052 Aluminum coil an extremely sought-after alloy across a variety of industries due to its remarkable properties. Here are a few of its important advantages:

- Excellent Corrosion Resistance

- Natural Oxide Layer:5052 aluminum creates an oxide-protective layer on its surface when it is exposed to oxygen. The oxide layer acts as a barrier against corrosion, and it is highly resistant to elements.

- Marine Environments: This format is specifically appropriate for marine environments in which exposure to saltwater and extreme conditions are frequent.

- Chemical Resistance: The alloy is able to resist a wide spectrum of chemicals. This allows it to be used in industries such as chemical manufacturing and Food processing.

- High Strength-to-Weight Ratio

- Lightweight: 5052 aluminum is relatively lightweight compared to other metals, which is advantageous in applications where weight reduction is crucial.

- Structural Strength: Despite its light weight, HTML0 is extremely strong structurally and is the ideal choice for components that require durability as well as lightness.

- Good Formability

- Easy to Shape: 5052 aluminum is highly formable, allowing it to be easily shaped into various complex components through processes like bending, stamping, and deep drawing.

- Versatility: This versatility makes it suitable for a wide range of applications, from automotive parts to consumer goods.

- Excellent Weldability

- Strong Joints: 5052 aluminum is a great material to weld using various methods, resulting in solid and durable joints.

- Consistent Properties: The welded joints preserve the original properties of the alloy as well as ensuring the structural quality of the constructed structure.

- Moderate Conductivity

- Electrical Conductivity: Although it isn’t as strong than pure aluminium, the 5052 still has some electrical conduction. This makes it ideal for applications which require electrical conduction for example, electrical enclosures and heat sinks.

- Thermal Conductivity: Show moderate thermal conductivity which makes it a great option for a component that disperses heat.

Application

- Transportation:

- Automotive: It’s utilized in car body panels as well as exteriors. 5052 aluminum alloy may be used to create structural components such as suspension parts and chassis engine blocks frames, and chassis engine blocks. Its weight-to-weight and light weight ratio could help enhance the efficiency of energy usage and improve the performance of vehicles.

- Aerospace: Aerospace Industry is a highly strict requirements for the material it uses. 5052 aluminum alloy is capable of meeting the requirements of these industries. It’s used in aircraft wings, fuselage sections, landing gear, and other critical components. Its combination of strength, corrosion resistance, and formability makes it an ideal choice for applications where safety and reliability are paramount.

- Marine: The ocean is known for the extreme conditions it has to endure including exposure to seawater, humidity, ultraviolet radiation as well as the humidity. The outstanding resistance to corrosion of the alloy 5052 aluminium makes it a great choice for decks of ships, as well as the hulls of marine structure. The alloy’s lightweight properties help in enhancing fuel efficiency and reshapeability.

2. Construction:

- Architectural cladding:5052 Aluminum alloy is a variety of metals which can be utilized for the construction of outdoor paneling. It features an elegant and contemporary design with a long-lasting, durable quality and low maintenance costs. It is ideal for building curtains and wall panels and roofs, and other elements that are designed for use outside.

- Building materials: Other than building exterior walls the alloy 5052 is utilized in a variety of construction materials, including windows, doors frame, frames, and structural elements. Its malleability allows it to be moulded to create intricate patterns. The strength and durability of the alloy can last for an extended period of time.

3. Consumer Goods:

- Electronics:Electronics industry relies heavily on 5052 aluminum for the production of heat sinks, casings and additional elements. Its exceptional thermal conductivity permits efficient heat dissipation, which aids in preventing overheating as well as providing maximum performance.

- Appliances: 5052 aluminum alloy can be extensively used in household appliances such as air conditioning, refrigeration equipment, as well as kitchenware. Its strength and resistance to corrosion make it the perfect option for components subject to humid and harsh conditions.

- Packaging: 5052 alloy of Aluminium is also used for packaging, including aluminium foils, containers, and even aluminum bottles. Its lightweight characteristics as well as its barriers make it the perfect material to package drinks and food items.

4. Industrial Applications:

- Chemical processing:Chemical industry requires materials that are able to withstand the extreme conditions. The resistance to corrosion in 5052 aluminum alloy makes it an ideal choice for pipes, tanks and other machinery.

- Food processing:In the industry of food processing sanitation and safety are of paramount importance. The non-toxic features and smooth and clean surface of the alloy 5052 make it the preferred material for machines, equipment, and containers.

- These are just a few examples of the many applications of 5052 aluminum coil. Its versatility, durability, and excellent properties make it a valuable material in a wide range of industries.

FAQ

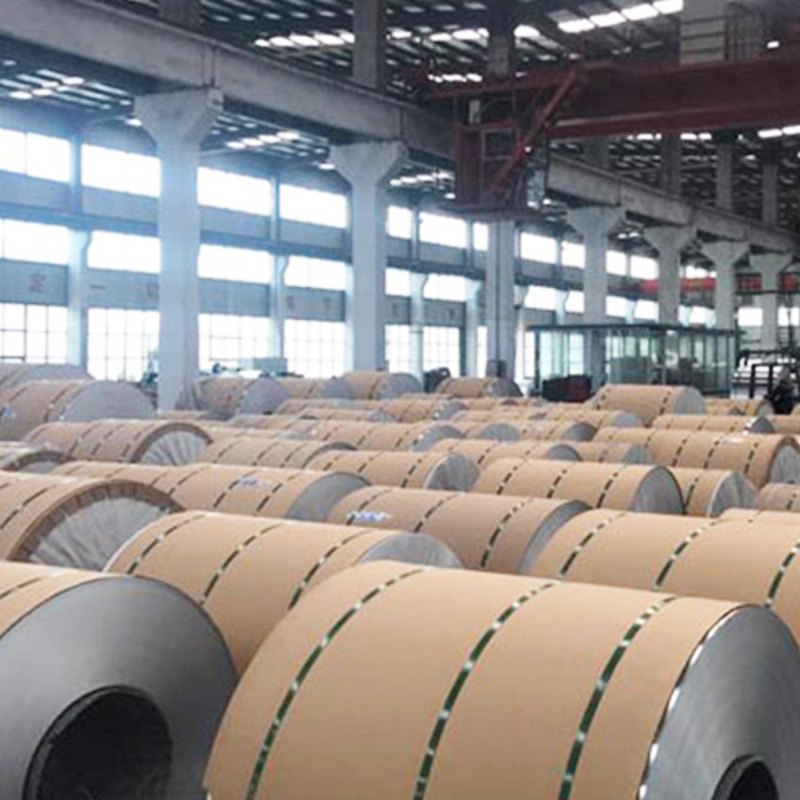

Q1: Are you a trading company or manufacturer?

A: We are a leading aluminum cookware manufacturer in western China.

Q2: What product information do I need to provide?

A: You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q3: How long does your delivery time take?

A: In general, our delivery time is within 30-45 days, and may be delayed if the demand is extremely large or special circumstances occur.

Q4: Can I go to your factory to visit?

A: Of course, we welcome customers from all over the world to visit our factory. However, some of the plants are not open to the public.

Q5: What is your working time?

A: In general, our online service time is Beijing time: 8:00 AM-22:00 PM, after 22:00 PM, we will reply to your inquiry during the next working day.