How to Store Aluminium Circles to Avoid Oxidation?

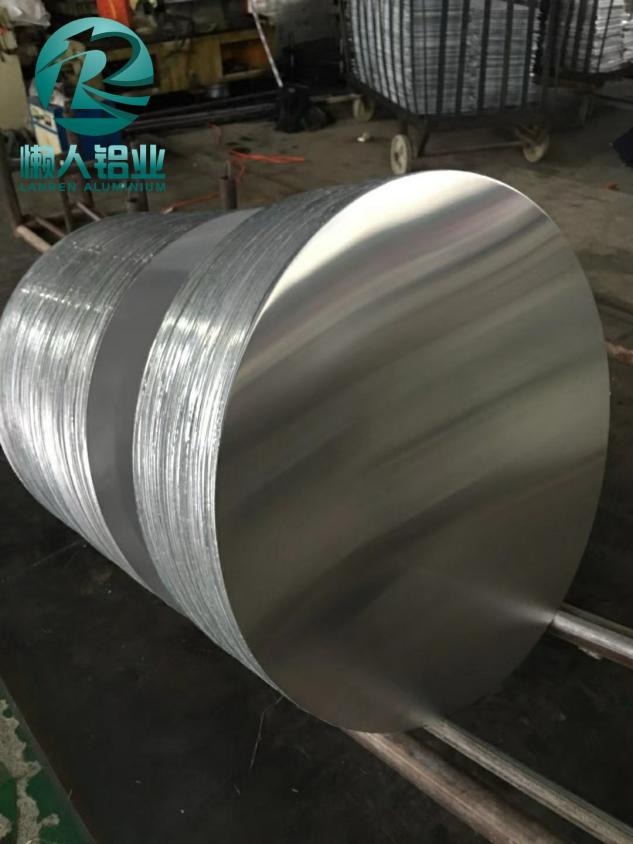

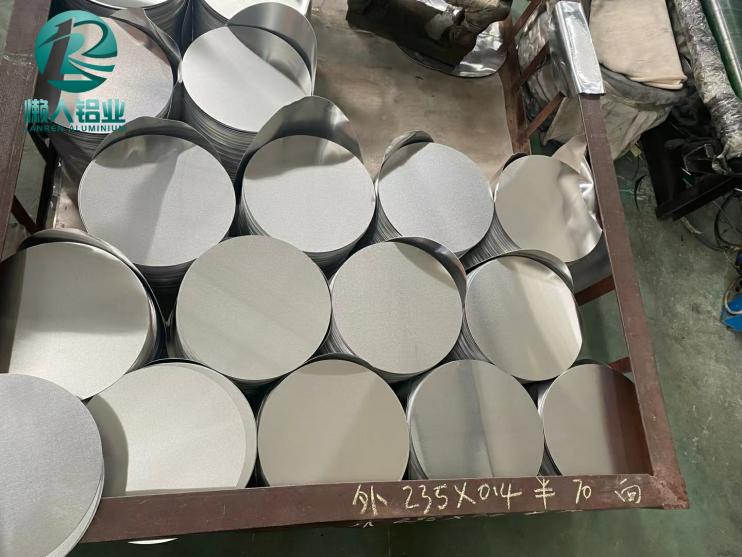

Aluminium circles find usage in a variety of industries like cookware, metal stamping, deep drawing, and spinning, where surface quality is the processing and the final product appearance’s critical factor. Oxidation on aluminium circles can still happen during the storage of even high-quality ones if the conditions are not properly controlled.

Moisture, exposure to air, and incorrect packaging are the most common reasons for the surface to be discolored and have white oxidation marks. Often, these problems show up before the material can be used in production, which in turn causes quality problems and material loss.

This blog offers a comprehensive guide to practical and proven methods of storing aluminium circles in such a way as to not only help minimize oxidation but also keep the surface quality stable.

Why Aluminium Circles Are Prone to Oxidation During Storage?

Aluminium is a metal that reacts easily. The exposure of aluminium circles to air results in the reaction with oxygen and water to form an oxide layer on the surface. The oxide layer is thin, natural, and unavoidable, but too much or uneven oxide during storage may cause problems with the quality of the product.

The acceleration of oxidation is mostly brought about by the following factors:

- Humidity: The most important factor is moisture in the air. High humidity doubles the rate of oxidation.

- Oxygen exposure: The exposure to air for a long time allows the process of oxidation to continue slowly over time.

- Temperature changes: Temperature variations may lead to moisture build-up on the surface of aluminium circles.

- Surface condition: Aluminium circles with a polished or bright finish are more prone to oxidation compared to rough surfaces.

- Material purity: Pure aluminium circles, like 1050, 1060, and 1070, are more likely to oxidize than alloyed materials.

Oxidation not only influences the appearance but also the deep drawing, spinning, anodizing, and coating processes as well. This is the main reason why the storage of aluminium circles is regarded as an integral quality control measure.

Ideal Storage Environment for Aluminium Circles

The proper storage conditions are the premises that oxidation is prevented.

Temperature Control

Aluminium circles are to be kept in an environment with stable temperatures, ideally between 15°C and 25°C. The sudden temperature changes are to be avoided because they can lead to condensation of moisture on the metal surface.

Humidity Control

Humidity is the paramount factor. It is advised to keep the aluminium circle storage at a relative humidity of less than 50%. Dehumidifiers or dry storage rooms are to be used in humid areas.

Storage Location

- Place aluminium circles on skids or pallets, not directly on the floor

- Do not position them to the sides of the walls where condensation might happen

- Create a good airflow around the circles, but do not let the air come straight from outside

Environmental Cleanliness

It is not permissible to keep aluminium circles nearby:

- Treatments or cleaning agents

- Acidic or alkaline materials

- Steels that may lead to contamination or rusting

A warehouse that is clean, dry, and stable drastically cuts down on the chances of oxidation.

Proper Packaging Methods to Prevent Oxidation

Proper packaging is a must to safeguard aluminium circles from moisture and air exposure during their storage. Various packing methods give different degrees of oxidation protection and should be chosen according to the storage duration and the environmental conditions.

Common Packaging Options for Aluminium Circles

| Packaging Method | Best For | Oxidation Protection | Notes |

| Moisture-proof paper + PE film | Short to medium-term storage | Medium | Cost-effective and widely used in industry |

| Aluminium foil / barrier bag | Long-term storage | High | Strong moisture and oxygen barrier |

| Barrier bag + desiccant | Export and humid environments | High | Desiccant must be replaced if opened |

| Vacuum packaging | Long-term storage and overseas shipping | Very High | Requires re-packing after opening |

Practical Packaging Tips:

- It is good practice to use the packaging method in accordance with the humidity and storage duration level.

- Packaging must be kept sealed and intact at all times.

- Aluminium discs should be used quickly after opening or re-packaged correctly.

Handling and Storage Best Practices in Industrial Settings

After proper packaging of aluminium circles, surface quality and oxidation prevention depend on careful handling and stacking. The best packaging will be ineffective if circles are dropped, dragged, or not stacked properly during storage or transport.

- Handling instructions

To prevent transferring fingerprints, sweat, or oils to the surface, handlers should always wear clean and dry gloves when moving aluminium circles. Direct contact with the skin can cause very small oxidation spots or discoloration. Do not slide circles over each other since it may lead to scratches or dents, especially in the case of polished or thin circles.

- Stacking Practices

Aluminium circles should be laid in equal layers on the pallets or trays. Therefore, there must be protective layers between each circle. Do not stack them too high, as the excessive weight can either deform the lower layers or cause damage to the edges of the circles. If possible, store the circles vertically in racks or separators to reduce surface contact and allow for better air circulation.

- Inventory and Inspection

To avoid the stocks of older materials being stored for longer periods, the “First In, First Out (FIFO)” method should be used. Packaged circles must be checked regularly for moisture, condensation, or damage to packaging, and any compromised wrapping should be replaced immediately. Manufacturers can, with careful handling, proper stacking, and routine inspection, significantly lower the oxidation risks and, thus, maintain the quality.

Common Storage Mistakes That Lead to Aluminium Circles Oxidation

A lot of oxidation issues can be said to be due to avoidable errors, and among those are:

- Unprotected storage of aluminium circles in high humidity warehouse

- Open the packaging left after quality control

- Directly putting aluminium circles on the ground

- The proximity of aluminium circles to steel products, which can lead to electrochemical corrosion

- A long period of keeping stock without quality control

Usually, these errors remain hidden until the aluminium circles are processed, resulting in production delays and increased waste. Be careful!

Oxidation during storage is a typical challenge for aluminium circles, but with good storage conditions, proper packaging, and careful handling, it can be efficiently prevented.

Being a manufacturer of professional aluminium circles, we realize the importance of storage and surface protection. If you have any inquiries about choosing the proper aluminium circle, the best packaging, or storage options for your production requirements, do not hesitate to get in touch with our team.

We will be able to provide you with customized guidance, deliver high-quality aluminium circles, and assist you in making sure that your materials remain in the best condition possible until it is time to use them!

Related Products