How to Cut Aluminum Sheet Easily & Precisely?

Cutting aluminum sheet may seem straightforward, but getting a nice, pinpoint, and clean cut can be trickier than you think. Many individuals end up with bent edges, ragged edges metal, or uneven lines — not due to the fact that aluminum is difficult to cut, but because they’re using incorrect techniques or tools. The art of smooth precise cutting can reduce time, reduce the amount of waste and elevate your work to “meh” to “professional.”

We go over the most efficient cutting techniques and help you choose the best method to meet your needs-No guesswork is required.

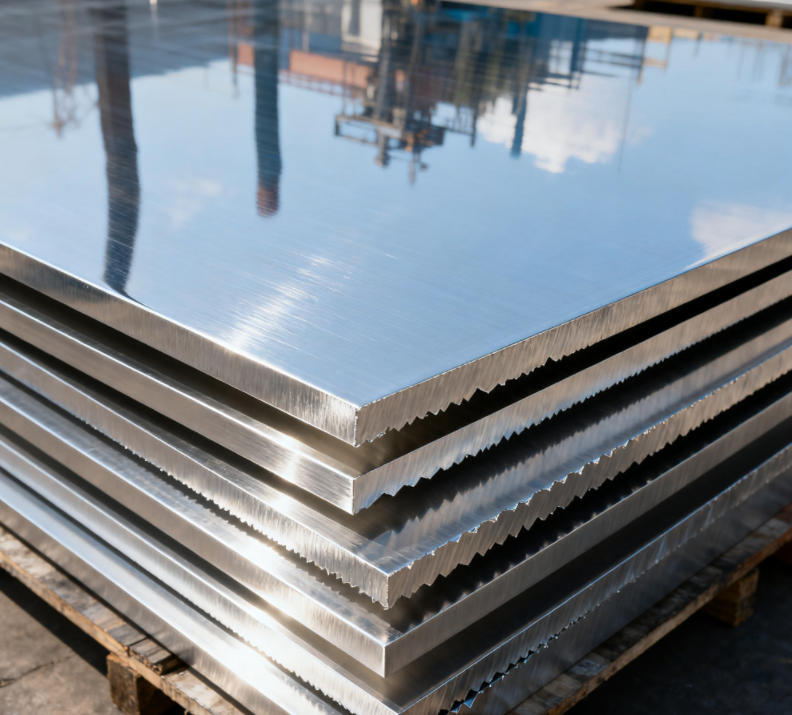

Understanding Aluminum Sheet and Why It’s Easy to Cut

Aluminum sheet is extensively used across various industries like construction and marine, automotive packaging, manufacturing, and construction. One of the main reasons for its widespread use is its superior combination of strength and usability.

As compared with steel, aluminium:

- Lightweight

- More flexible and soft

- Resistant to corrosion

- It is easy to machine and cut

But, size, thickness, and the treatment of the surface all affect the way that aluminum performs when cutting. Aluminum sheets that are thin can usually be cut with hand tools, but the thicker sheets require powered equipment or cutting techniques used in industrial manufacturing. The wrong tool can result in cutting edges that are deformed as well as excessive burrs and the waste of materials.

Knowing the characteristics of materials is the basis for precise cutting.

Preparation Matters More Than You Think

The process of precision cutting begins its initial steps before any blade makes contact with the metal surface. A proper preparation will ensure the smoothest cuts and minimizes errors.

A precise measuring and precise marking is essential. A steel ruler as well as a scribe or marker with a fine tip can help define a clear cutting line. For more extensive cuts, an edge straight or guide rail increases the precision.

Also important is the stability. Aluminum sheets need to be securely clamped on a flat work surface. Any slight movement in cutting may make the cutter move creating unbalanced edges or inaccurate measurements.

In the end, simple safety measures such as eye protection and gloves–do not only safeguard the user but also enable more secure, controlled cutting.

Best Methods to Cut Aluminum Sheet Easily & Precisely

Different cutting tools are used for different functions. Here are the most efficient techniques, separated by the thickness of the material, its precision level, as well as project size.

Tin Snips: Ideal for Thin Aluminum Sheets

Tin snips are among the most efficient tools to cut thin aluminum sheets. They’re ideal for sheets that are less than 1.6 millimeters in thickness.

This method can be described as:

- Simple and inexpensive

- Perfect for straight or curving cuts

- Typically, it is used for HVAC, roofing and light fabrication

Tin snips, however, require manual effort and can cause distortion to the sheet if utilized with care. They’re best suited for smaller projects, not large critical work that requires precision.

Hacksaw and Manual Blades: Controlled and Reliable

Hacksaws are a good alternative for thin aluminum sheets when power tools aren’t available. With a sharp blade it provides precision control and precise cutting lines.

This method works best for situations such as:

- Speed is more important than precision.

- Straight lines are cut or smaller sections

- Working in small spaces

Although they are slower when compared to powered devices, hacksaws offer superior accuracy when used in a patient manner.

Circular Saw and Jigsaw: Fast and Versatile

For thicker sheets or longer cutting, circular saws as well as Jigsaws that have aluminum-specific blades are very efficient. They significantly boost cutting speed, while preserving accuracy.

Circular saws are ideal for straight, long cuts Jigsaws are flexible to cut curves and intricate forms. The right blade selection and a moderate cutting speeds are crucial to prevent overheating and rough edges.

This technique is extensively used in workshops and for light industrial applications.

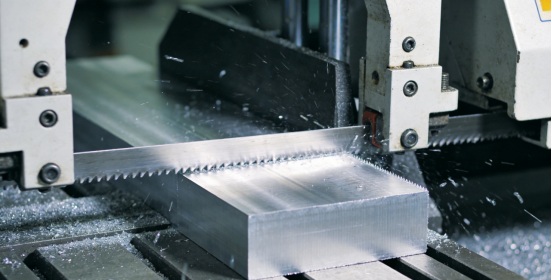

Band Saw: Precision for Complex Shapes

Band saws are a great tool for controlling and effortless cutting performance. They are especially useful for:

- Complex or curvy designs

- Consistent repeat cuts

- Sheets of aluminum that are medium to thick

Due to their durability and constant cut motion, bands saws create straight edges, with little or no need for finishing. This makes them suitable for fabrication in professional environments.

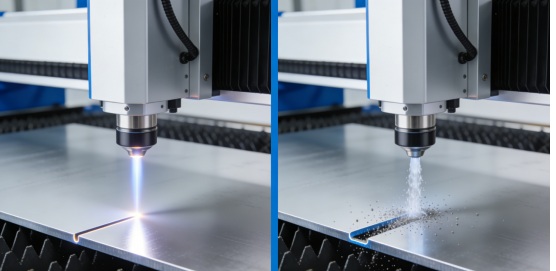

Laser and Waterjet Cutting: Industrial-Level Accuracy

If absolute precision is needed laser cutting and waterjet cutting are the best. These methods deliver:

- Extremely strict tolerances

- Soft, smooth edges with no burrs

- High consistency for complex designs

They are usually employed for industrial manufacturing, custom fabrication as well as high-value work. Although they are not suitable for workshops at home They are the benchmark for cutting aluminum with precision.

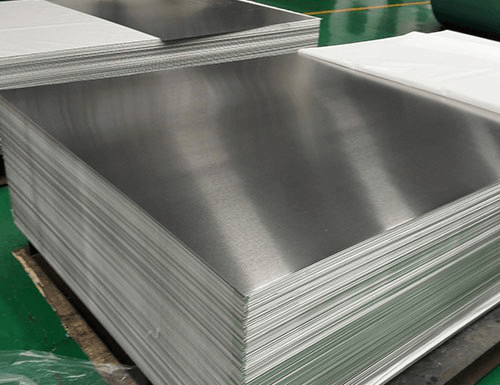

Choosing the Right Aluminum Sheet Makes Cutting Easier

Its Even the best cutting method cannot compensate for poor material quality; flatness, surface finish and alloy consistency all can have an effect on accuracy when it comes to cutting aluminum sheets.

High-grade aluminum sheets are easier to cut, produce fewer burrs, and produce cleaner edges – something especially crucial when working on projects requiring tight tolerances or visible finishes.

Lanren Aluminium offers an extensive range of aluminum sheet products suitable for cutting or fabricating applications, from thin and thick sheets suitable for cutting to industrial applications. Their sheets have proven themselves reliable throughout manufacturing, construction and export projects alike, offering precision and consistency every time.

Cutting aluminum sheet accurately and quickly doesn’t depend on purchasing the most expensive tool – rather it requires proper preparation, suitable tools, and high-quality aluminum sheets that enable clean cuts more often than ever before.

Aluminum offers unmatched versatility when combined with reliable material sourcing and careful technique for sheet cutting, which results in efficient processes that deliver professional results every time.

Related Products