Polyester (PE) Coated Aluminum Coil

Lanren Aluminum‘s Polyester Coated Aluminum Coil is engineered for decorative and industrial applications requiring vivid color, moderate weather resistance, and excellent formability. Ideal for interior panels, ceilings, signage, and building facades.

Product Description

- Polyester Coated Aluminum Coil is made from premium aluminum alloy that is extremely durable and corrosion-resistant. Furthermore, the special polyester paint coating has outstanding adhesion, flexibility, UV resistance, and long-term color retention even in harsh weather.

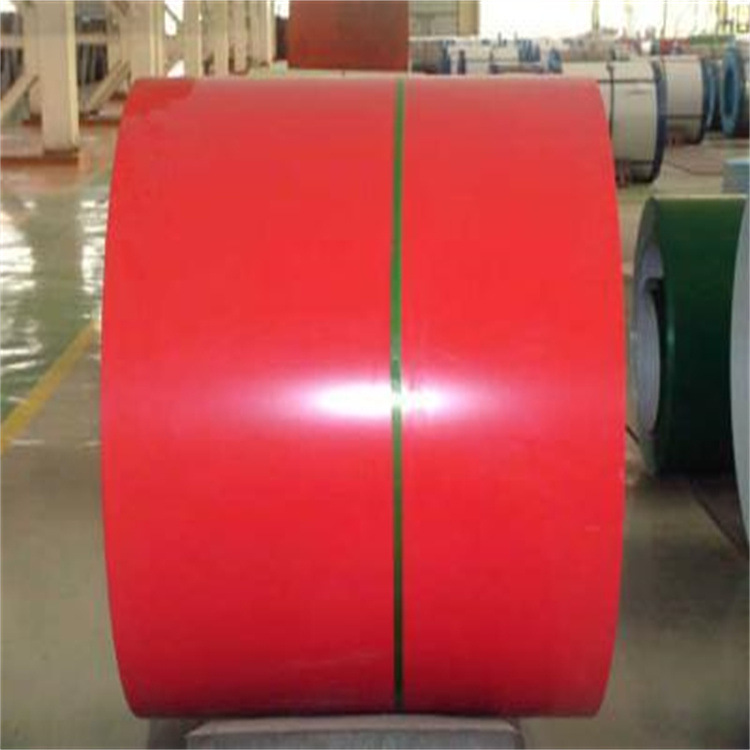

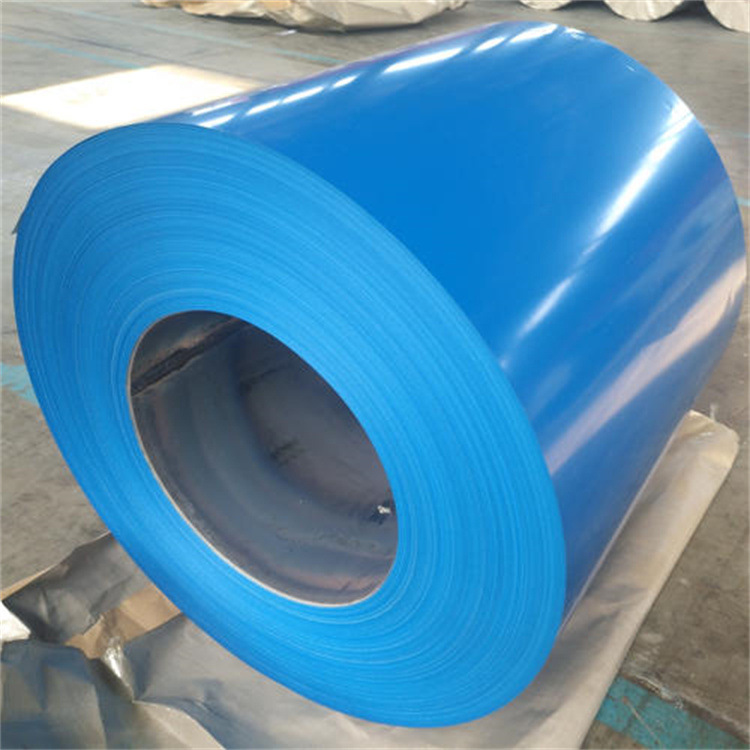

- Our Polyester Coated Aluminum Coils are available in different sizes and thicknesses to suit the specific requirements of your project. They are also available with different surface options like matte, smooth, or high gloss to bring visual appeal to your work.

- With a wide palette of colors, you can easily match your design vision, from classic neutrals to vibrant hues. The polyester coating provides strong resistance to weathering, chalking, and fading, making the aluminum coil ideal for both interior and exterior applications.

- Our versatility makes our PE-coated aluminium coils a top option for building facades, ceilings, roofing system,s interior panels, signs, and the automobile industry. They’re committed to sustainability and are recyclable and produced using environmentally friendly processes to provide a safe product that is safe for both humans and the environment.

Specifications of PE-Coated Aluminum Coil

| Aluminum Alloy | AA1100; AA3003; AA5005 |

| Coil thickness | 0.18mm,0.21mm,0.25mm,0.30mm,0.40mm,0.45mm,0.50mm |

| Coil width | 1240mm, 1270mm, 1520mm, |

| Coating thickness | Over 16 micro |

| Diameter | 405mm, 505mm |

| Coil weight | 2.5 to 3.0 tons per coil |

| Color | White series, metallic series, Dark series, Gold series( accept color customs) |

PE Coated Aluminum Coil Color Choice

Polyester-coated aluminum coils are offered in an incredible array of colors-from deep solids to bright pastels matched to complement specific architectural styles. The PE coating offers superior gloss retention and color stability, keeping the finish bright and consistent. Whether you have a classic neutral, a modern metallic tone, or even a custom-matched shade, your PE-coated coil will provide long-lasting aesthetic reliability.

Advantages of PE Coated Aluminum Coil

The polyester-coated aluminum coils offer a variety of advantages that make them an attractive choice in a variety of industries, including construction as well as automotive, and home appliances. Here are some of their benefits:

- PE coatings offer outstanding protection against the elements. This makes the coil impervious to UV radiation, water intrusion, as well as temperature fluctuations, making it more durable and durable even under harsh outdoor conditions.

- PE coatings are able to provide an array of finishes and colors, which creates aesthetic versatility. The high gloss finish adds aesthetic appeal, making PE an ideal choice for decorative and architectural applications.

- The PE coating forms a protective barrier that prevents the aluminum from oxidizing and corroding. This is crucial for applications where the material is exposed to moisture or chemicals.

- PE-coated aluminum coils are generally more affordable compared to other coating materials like PVDF (polyvinylidene fluoride). This makes them a cost-effective solution for large projects and applications where budget constraints are a consideration.

- The smooth surface of PE-coated aluminum is easy to clean and maintain. It resists dirt and stains, requiring minimal upkeep to retain its appearance and performance over time.

- PE coatings are firmly adhered to aluminum substrates, assisting in keeping their coating intact throughout processing, handling, and the installation process. This adhesion strength contributes to the longevity and durability of coated materials.

Where Can PE Coated Aluminum Coil Be Used

The applications of PE-coated aluminum coils span many different areas, from interior decoration to exterior construction, and even beyond.

- For indoor use

In buildings, PE-coated aluminum coils shine as a wall option for covering. Its smooth surface and diverse colors are ideal for modern interior design. In addition, it’s an extremely well-liked choice for ceilings, that’s where it creates an elegant, contemporary look. Due to its resistance against water and staining, it’s a fantastic material for areas with high traffic, such as kitchens and bathrooms.

- For outdoor use

For external facades, PE-coated aluminum coil is the most popular material to clad buildings. It offers a sturdy and attractive exterior while also protecting from the elements. Its weather-resistant qualities make it suitable for roofs and canopies. In architecture, it can be used as an ideal material to build stunning columns and pillars.

- For other use

Beyond the building sector, the PE-coated aluminum coil is found to have applications in a variety of industries. It is a crucial component of aluminium composite panels (ACPs), which are large-format panels that are used for signage, construction, as well as interior designs. The coil’s light but sturdy design makes it a great option for signs advertising that are durable even for outdoor settings. In addition, it’s used in the production of household appliances, ensuring an attractive and durable surface for components and panels.

The potential applications of PE-coated aluminium coils are extensive. Any job that requires a combination of durability, strength, resistance to corrosion, as well as aesthetic appeal, could be a use for this type of material.

Lanren PE-Coated Aluminum Coil Quality Control

To ensure high quality, we need to rigorously monitor every phase in the production process.

- Raw Material: We produce PE-coated aluminum coil in-house and test each batch to ensure purity and absence of impurities. Chemical composition is tested to ensure that it meets the requirements of our customers.

- Quality Assurance: Our PE-coated aluminum coil is produced and controlled in accordance with international standards. Every product is subject to stringent quality tests prior to shipment.

- Material Testing: Our facility can conduct a variety of tests, including PMI testing, Ultrasonic testing, mechanical tests, flaring tests, spectrochemical analysis, and IGC. We are open to stage-wise inspections by your representative or from independent inspection agencies.