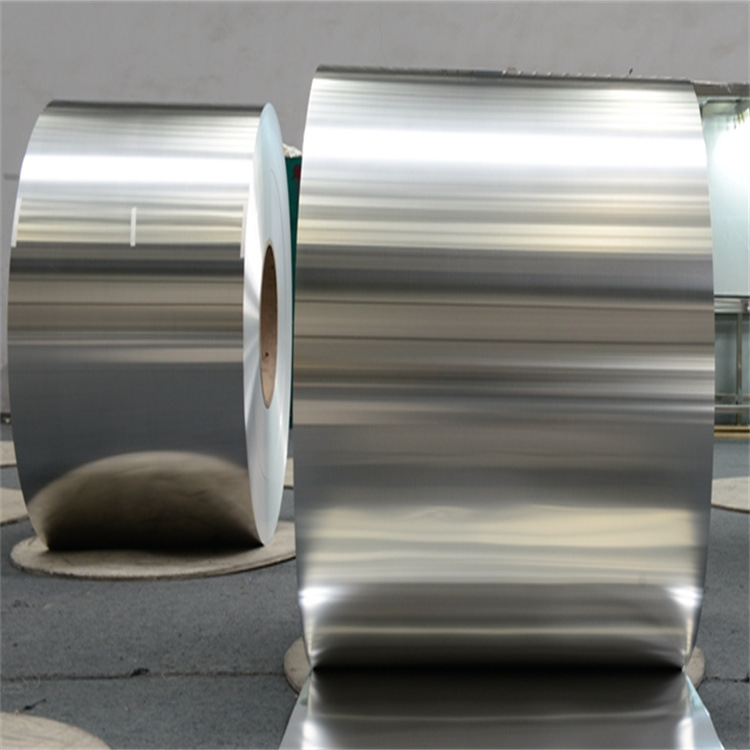

3003 Aluminum Coil

3003 Aluminum Coil is a versatile aluminum alloy. It offers strong corrosion resistance and great form-ability. Manganese is its main alloying element. This element gives 3003 higher strength than pure aluminum.

The 3003 Aluminum Coil suits many uses. You can find it on roofs, exterior walls, cookware, and heat exchangers. It handles tough conditions and keeps its shape.The alloy is easy to cut and form. Offer different thickness and surface treatment options to meet a wide range of industrial needs.

Specifications of 3003 Aluminum Coil

| Specification | Value |

| Temper | O, H12, H14, H16, H18, H19 |

| Thickness | 0.004″ to 1.000″ |

| Width | 16″ to 60″ |

| Length | Up to 10,000 feet |

| Yield Strength | 10,000 to 12,000 psi |

| Tensile Strength | 20,000 to 22,000 psi |

| Elongation | 35-40% |

| Hardness | 50-70 Brinell |

| Applications | Roofing, siding, gutters, cookware, automotive components, and more |

Chemical Composition of 3003 Aluminum Coil

| Element | Aluminum (Al) | Copper (Cu) | Manganese (Mn) | Silicon (Si) | Iron (Fe) | Magnesium (Mg) | Zinc (Zn) | Titanium (Ti) | Other Elements |

| Weight Percent | 97.0-99.0 | 0.10-0.40 | 1.0-1.6 | 0.40-0.80 | 0.7 | 0.2 | 0.1 | 0.15 | 0.1 |

Advantages of 3003 Aluminum Coil

- 3003 aluminum coils are built with corrosion resistance, and therefore work well in moist or chemically contaminated environments. The alloy is enriched with manganese, which improves its strength when compared with pure aluminum. It’s easily bendable or stamp, and then weld, making it a breeze to work with. They are light which means they save fuel while transporting as well as reducing labor and scaffolding costs at the site.

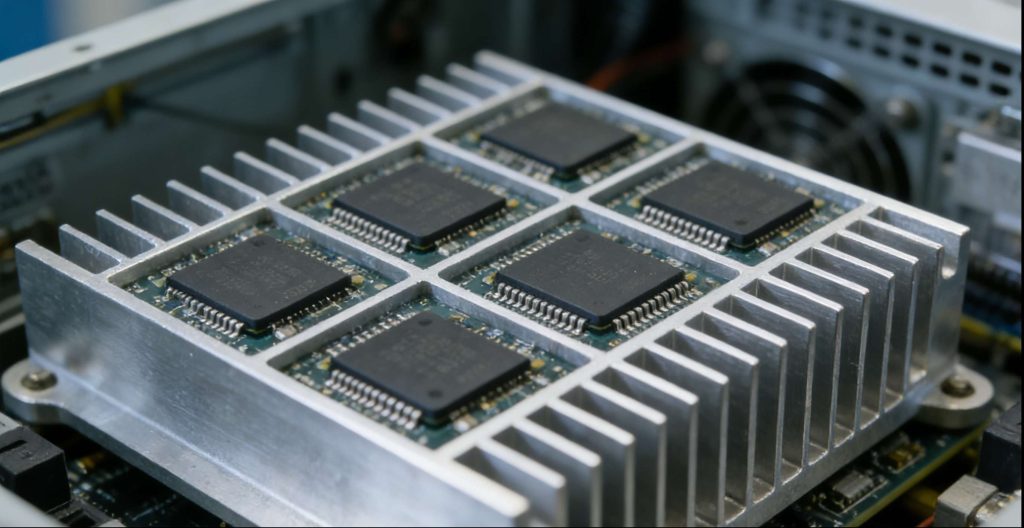

- Additionally, 3003 aluminum has excellent conductivity to electrical and thermal energy which makes it a preferred option for heat exchangers and electrical components. The surface is able to be odised or coated to preserve its appearance for many years.

- Furthermore, 3003 aluminum coils are practical as well as affordable in the HVAC, automotive and food packaging sectors, so its lifespan the entire coil could be reused which reduces waste and improves sustainability in the environment.

Applications of 3003 Aluminum Coil

As an alloy of aluminum, 3003 aluminum coil can be widely used in various industries because of its superior property in terms of chemical and physical properties. We will then look at the applications specific to 3003 aluminum coil across various sectors.

- Aerospace field: In the aerospace field, 3003 aluminum coil is commonly used in the production of frames for aircraft, skins for aircraft frames for fuselages beams, rotors, beams propellers, and other important components because of its lightweight weight, high durability and resistance to corrosion. Additionally it is also utilized to make rocket shells and spacecraft sidings.

- Automobile manufacturing field: In the automobile manufacturing field, 3003 aluminum coils are employed to manufacture thin plates that are placed on the exterior of the vehicle including doors, hoods, and other components. It is believed that using 3003 aluminum coil could significantly lower the overall weight of a vehicle, boost the efficiency of fuel and decrease carbon emissions.

- Electronic equipment manufacturing field: 3003 aluminum coil is also used in the production of electronic equipment specifically for electronic device housings, heat-sinks and other components. Its high conductivity and excellent heat dissipation make it ideal for the long-term operation of electronic equipment.

- Construction industry: In the construction industry, 3003 aluminum coils can be utilized in building materials, for exterior wall panels as well as roof panels. Their light weight properties aid in reducing the weight of the construction, enhance the resistance to earthquakes, and cut down on the costs of transportation and installation.

- New energy field: With the rapid development of the market for new energy vehicles 3003 aluminum coils play a significant role in the power battery shell materials. Its strength and excellent processing capabilities makes it the most preferred material for the production of Power battery shells.

- Chemical and other industries: In addition, 3003 aluminum coils are utilized in the petroleum, chemical pharmaceutical, and other industries to make various pipes and containers. The corrosion resistance of 3003 ensures its the long-term viability of these industries.

Packaging and Delivery of 3003 Aluminum Coil

- Standard airworthy export packaging. Wooden pallets with plastic protection for coils and plates;

- According to customer requirements, the packaging can face the sky or the wall;

- 16-20 MT can be put into 20FCL, the shipping price is much cheaper than 40FCL;

- Delivery time: 15-35 days after receiving the LC or 30% deposit.

FAQ

Q1: Are you a trading company or manufacturer?

A: We are a leading aluminum cookware manufacturer in western China.

Q2: What product information do I need to provide?

A: You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q3: How long does your delivery time take?

A: In general, our delivery time is within 30-45 days, and may be delayed if the demand is extremely large or special circumstances occur.

Q4: Can I go to your factory to visit?

A: Of course, we welcome customers from all over the world to visit our factory. However, some of the plants are not open to the public.

Q5: What is your working time?

A: In general, our online service time is Beijing time: 8:00 AM-22:00 PM, after 22:00 PM, we will reply to your inquiry during the next working day.

Q6: What’s the MOQ?

A: Typically, the trial order will be accepted. The minimum order quantity (MOQ) can be determined based on the specific products.