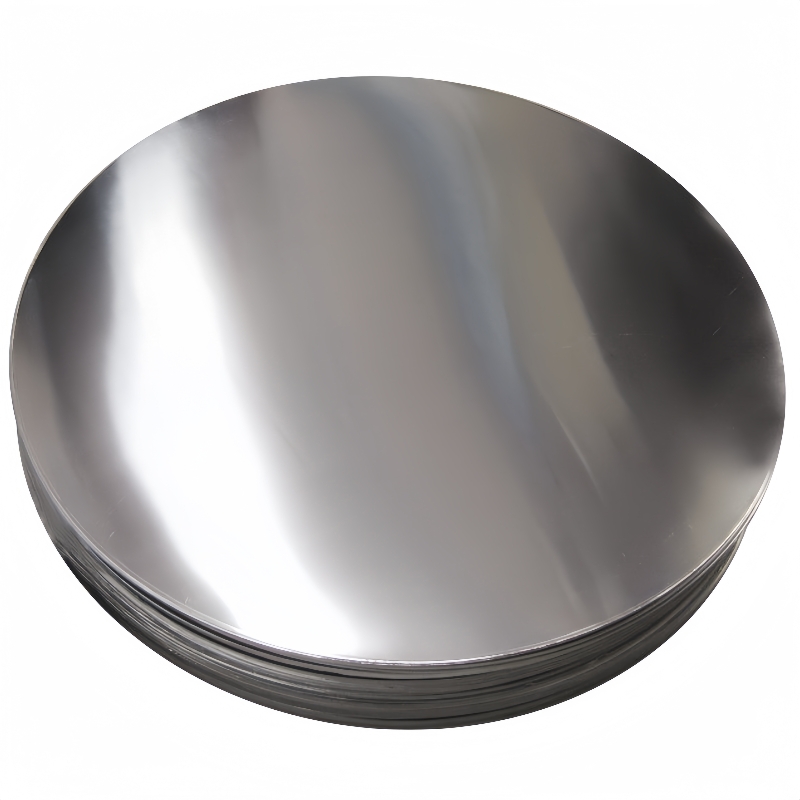

How to Verify Quality When Importing Aluminium Circles from China?

As with any business, when importing aluminium circles from China, getting high-quality products is crucial throughout your company’s operations. Fortunately, there is an abundance of China aluminium circle manufacturers to choose from; however, checking for quality control during production is essential in avoiding expensive damages and slowdowns.

This guide will address the most important steps to evaluate aluminium circle quality, starting with choosing the right manufacturer and finishing with pre-shipping inspections.

Aluminium Circles: Grades and Standards

Knowing the appropriate material grade and applicable industrial standards is necessary when importing aluminium circles from China so that you can make the right selection for your needs. Different grades of alloys have different levels of strength, flexibility, and resistance to oxidation, so it is important to choose the correct grade based on your requirements.

Common Aluminium Circle Grades

- 1xxx series (1050, 1060, 1070) – Pure aluminum with superb thermal conductivity and corrosion resistance. Used in cookware, lighting reflectors, and chemical containers.Backend thermals

- 3xxx series (3003) – Contains manganese, which improves the strength while still being easy to work with. Commonly used in kitchen utensils, signage, and fuel tanks.

- 5xxx series (5052, 5083) – Allied with magnesium for increased strength, making it useful in marine, automotive, and industrial divisions.

Key Industry Standards

Manufacturers must adhere to strict international regulations such as:

- ASTM B209 (USA) – Covers specifications for aluminium sheet and plate.

- EN 573 (Europe) – States the chemical composition along with mechanical properties.

- GB/T 3880 (China) – Chinese national standard for aluminium and aluminium alloys sheets.

Sourcing aluminum circles from China requires specific suppliers, one that conforms to these set parameters as well as provides physical documentation certifying their materials’ compliance, assures long-term serviceability, not just reliability, but performance savings within an organization’s global expenditure.

Choosing a Reliable Aluminium Circle Manufacturer in China

When choosing a Chinese aluminium circle supplier, the factors of product quality, timely delivery, and long-term business relationship are the most important considerations. To spot a reliable supplier, consider the following:

- Check Industry Experience

Choose manufacturers with 5 to 10 years of experience producing aluminum circles. Their extensive experience provides them with a better understanding of alloy selection and surface treatment.

- Verify Certifications

Producers that have ISO 9001 or SGS certification, or products marked as RoHS certified, undergo environmental compliance and adhere to international standards. They also show strict control over production variables.

- Assess Production Capabilities

There should be:

- Sophisticated cold rolling and blanking machines for precise measurements.

- Suitable annealing furnaces to enhance the material flexibility.

- In-house testing laboratories to test quality before shipping.

- Assess Customer Reviews

For Applause all-audio customer review comments, take note of websites like Alibaba and Global Sources. Good vendors sing praises of product, shipping promptness, and post-sales support with lengthy positive reviews.

- Request samples & factory visit

These sample requests usually involve products, e.g., thick tolerance putting surfaces to test, and performance when formed. Where possible, buy escorts online who guide you through visiting factories, inspecting conduct accepted standards, carrying out inspections, third-party independent, rational, tested procedures, criteria, output mark acceptance, general loyal witness reliability, and protested conditions.

Key Quality Checks of Aluminium Circles Before Ordering

Quality checks in advance are important when planning to place aluminum circle orders. Defects can make the products unreliable. Here is a detailed description of how to confirm quality.

Certification of Measuring Tools

The manufacturer must be requested for an MTC Mill Test Certificate because the correct grade was used, such as 1050, 3003, or 5052, but received a lesser grade.

Mechanical properties include tensile strength, elongation, and hardness, so they should pass with flying colors.

Surface quality needs to maintain smoothness and imperfection absence to measure perfection.

Milling provides no certification guarantees; substandard material will be milling waste that fails during prototyping.

Evaluation Of Check Samples

Make sure sample circles have the following criteria:

- Dimensional accuracy, inclusive of diameter measurement, edge straightening, and thickness verification.

- Checking for oxidation, surface scratches pits ensures performance appraisal.

- Formability, including deep drawing or spinning tests, depicts workability.

Do these sample evaluations fail? Make a claim and re-evaluate your supplier and designs based on worst-case assumptions.

Inspection Of Factory

Validation questions for modern cutting machines come under:

- Monitoring assignments, current regulations encompass external factories, labs, and self-regulated zones, down to rest like having locations for on-site assessment alongside sequential information acquisition practices

- Storage environments – Lack of proper handling methods eliminates the chance of destruction by moisture and contamination.

- Visiting the facility determines the genuineness and production capacity of the factory.

Adhering to these steps helps minimize risks and ensure the supplier meets quality expectations prior to placing an order. Investing time in pre-order verification reduces costs and prevents delays within your supply chain.

Quality Inspection During Production

Defect prevention and adherence to industry standards must be in place when keeping production of aluminum circles. The following is how to maintain quality control:

- In-Process Checks – Monitor key checkpoints like blanking, annealing, and finishing, tracking smoothness of the surface as well as dimensional checks. The layers monitored of every circle should not go beyond the stated tolerances.

- Third Party Inspections – Agencies of quality inspections integrated with SGS, BV, or Intertek can independently test for prejudiced analysis. They check sample metallographic cross-sections of material composition, mechanical characteristics, and surface texture.

- Batch Testing – Check tested samples against given standards such as hardness levels, tensile strength readings, and corrosion resistance of various batches of produced aluminum circles.

- Pre-Shipment Audit – Verification against requirements of contract, approved alloy grade, size, and finish, for oxidation, dents, or scratches, to ensure the product is circle matching alloy.

Stringent checks at all stages of manufacturing assist higher conformity with international standards and lower risk to deliver supreme grade performance aluminum circles that are engineered to your applications.

Why Verify Aluminium Circles Quality Important

Quality checks on aluminium circles before importation from China are key to the reliability of the product as well as the satisfaction of the customers.

- Defective circles can cause problems in manufacturing, lead to wastage, and even present safety risks with products such as cookware and automobile parts. Well-implemented quality control helps you avoid getting materials that are of such low quality that they cause delays in production and damage your reputation as a brand.

- Quality inspection is also key to cost control. Low-quality aluminium will incur additional processing costs and an increased likelihood of a failed fabrication. High-quality inspections save you from costly returns, replacements, and litigation due to non-conformance to acceptable industry practices.

- Moreover, great quality ensures lasting relationships with your suppliers. Manufacturers will have confidence in you as a customer and will constantly meet the production standards that you require.

- Trusted quality inspections will also improve your defense against all the weaknesses in your operation, finances, and supply chain, as well as your products. Investing in quality now will result in less trouble and a higher likelihood of success in the future.

Final Thought

It requires rigorous supplier screening and quality checking to source good-quality aluminium circles from China. Through material certification checking, sampling test, and factory inspection, you can get durable and reliable products for your business.

Get a certified China aluminium circle manufacturer today and enjoy a hassle-free import experience!

Related Products