Aircraft Aluminum Sheets vs. Steel: Why Aluminum Cuts Aircraft Weight?

Weight reduction is a fundamental element of modern aviation advancement. Every kilogram taken off of an aircraft improves the efficiency of its fuel supply which allows airlines to cut operating costs and increase distance. Additionally, it increases capacity of payload, allowing more cargo or passengers to be moved on the same flight. In addition, weight reduction reduces carbon emissions, which is in line with the industry’s drive towards sustainable development.

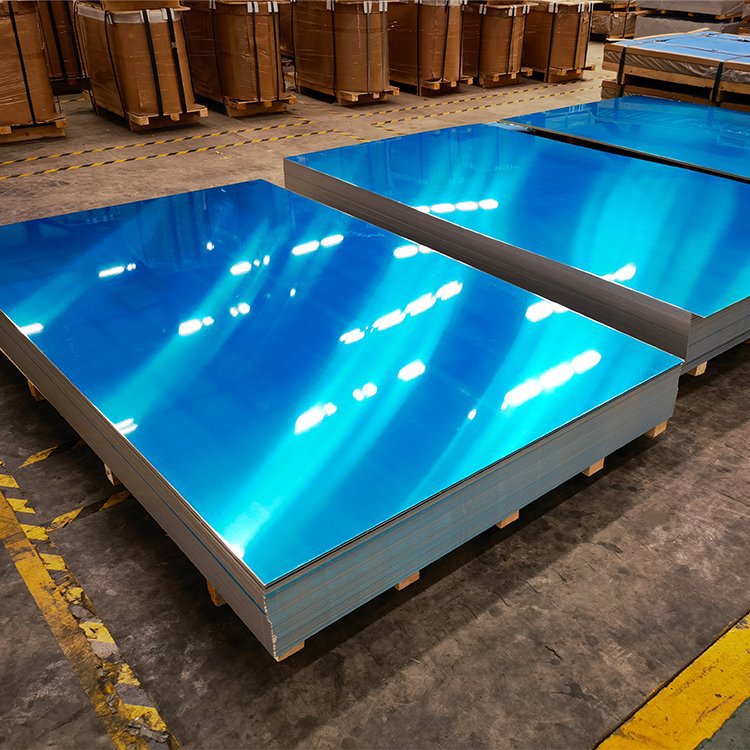

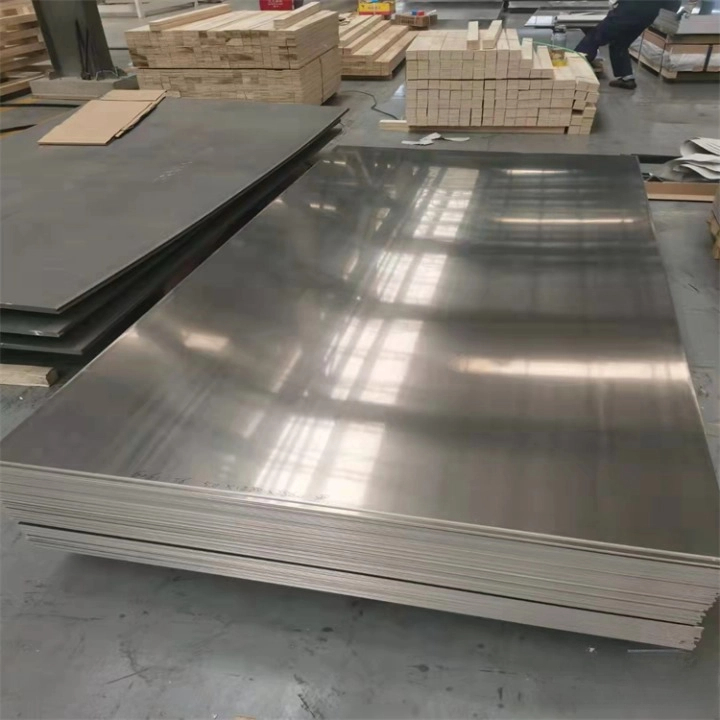

The selection of materials for aviation requires an array of factors to consider. Durability, strength, cost and weight play key parts, resulting in a complicated issue for manufacturers. One of the strategies that are being developed can be Aircraft Aluminum Sheets. These sheets have redefined the options for optimizing weight without sacrificing performance.

The Demand for Lightweight Materials in Aviation

Weight Influences Operational Costs and Sustainability

Aircraft weight has an direct influence on operating costs. The heavier planes use more fuel, which means higher costs and emissions. As time passes, these costs increase which makes weight reduction an important consideration for both environmental and economic reasons. Sustainability goals, specifically are a major reason for the increased demand for materials that can reduce dependence upon fossil fuels.

Steel’s Limitations in Modern Aviation

The use of steel has been a part of the tradition in aviation and is valued for its durability. However, its density makes it difficult for it to help reduce weight. As design for aircrafts improves to meet the strictest efficiency standards, the limitations of steel are becoming increasingly apparent.

The Rise of Aircraft Aluminum Sheets in Aerospace

Aircraft Aluminum Sheets have become an innovative technological breakthrough in aerospace material science. The unique properties they possess address demands of the industry’s greatest needs. Strong, durable and flexibility make them affixed to a variety of aviation applications. This makes them able to stand up to the rigors of flight while reducing the weight to the minimal.

Performance Comparison: Aircraft Aluminum Sheets vs. Steel

The table below highlights the most important performance metrics that demonstrate the reason why Aircraft Aluminum Sheets are superior over steel for weight reduction:

| Performance Metric | Aircraft Aluminum Sheets | Steel | Advantage for Aviation Weight Reduction |

| Density (g/cm³) | 2.7 | 7.8 | Aluminum is about 65% lighter than steel, which is directly impacting the weight of air-frames. |

| Strength-to-Weight Ratio | High | High strength but lower ratio due to higher density | Aluminum has enough strength for just a fraction of the weight. |

| Corrosion Resistance | Excellent | Prone to rust without protective coatings | Lowers maintenance requirements and helps avoid weight gain due to anti-corrosion treatments. |

| Fatigue Resistance | Superior for cyclic stress | Good but less adaptable to repeated stress | Provides long-term durability in stressful aerospace environments. |

| Cost-Effectiveness | Balanced | Lower material cost but higher operational costs | Aluminum can reduce life-cycle costs by efficiency in fuel. |

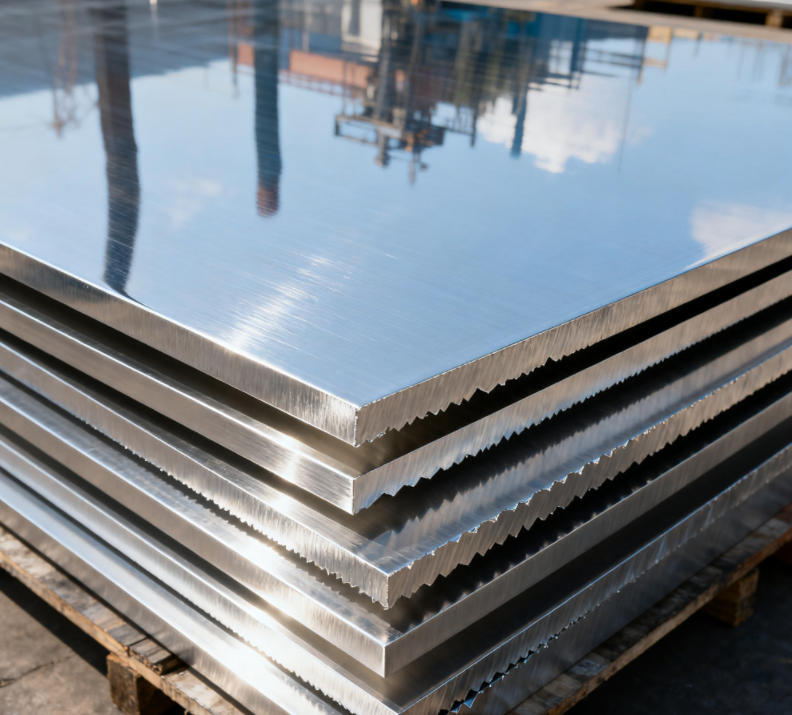

Density is the most important factor. With 2.7 g/cm³, aluminum is considerably more light that steel (7.8 g/cm3) and reduces airframe weight by 65 %. This decrease directly leads to greater fuel efficiency.

The strength-to-weight ratio also favors aluminum. Alloys such as 7075 offer 150 MPa of force at less than a quarter of the weight of steel and guarantee structural integrity without the excess weight. Steel, though robust, can’t compete with this level of strength.

Resistance to corrosion is another major benefit. The natural oxide layer in aluminum reduces rust, thus reducing the requirement for protective coatings with heavy weights that can add weight. Steel, on the other hand needs such coatings to protect against degradation, which can undermine efforts to reduce weight.

The resistance to fatigue is crucial to long-term performance. Aircraft Aluminum Sheets excel at withstanding the stress that comes with landings, takeoffs, and turbulence, providing durability across hundreds of flight hours. Steel, although durable is not as flexible to repeated stress.

The cost-effectiveness of aluminum is higher in the long run. Although steel could be cheaper upfront but aluminum’s energy savings and lower maintenance requirements reduce costs over the life of the investment which makes it a better long-term investment.

Advantages of Aircraft Aluminum Sheets in Practical Aviation Applications

Weight Reduction in Critical Components

Aircraft Aluminum Sheets drive weight reductions across key components of aircraft. Wings, fuselages and other structural components made of aluminum sheets are considerably lighter than steel counterparts, without compromising the strength. This decrease in weight improves overall efficiency.

Enhanced Maneuverability and Speed

A smaller mass can improve speed and maneuverability. Lighter aircraft respond faster to controls, increasing safety and efficiency. They can also climb to higher altitudes, reducing fuel consumption.

Compatibility with Advanced Manufacturing

A compatibility with the latest manufacturing techniques makes them more appealing. The ability to customize alloys lets manufacturers customize Aircraft Aluminum Sheets to specific requirements, while precise manufacturing ensures that the product is perfectly shaped. These capabilities speed up manufacturing and boost the efficiency of components.

Actual Impact and Compliance

Case studies from real-world situations highlight their effects. Airlines using aluminum sheets on fuselages and wings experience as much as 20% less fuel consumption. Manufacturers have noted a less complicated assembly process as well as lower maintenance downtime, leading to improved operational efficiency.

Compliance with strict aviation standards-such as ASTM and AMS specifications-ensures reliability. Aircraft Aluminum Sheets undergo rigorous tests to ensure they meet these standards, which gives manufacturers and airlines confidence in their performance.

The Ideal Choice for Aviation Weight Reduction

Lanren Aluminium has made a name for its place as a pioneer aircraft aluminum sheet manufacturer specializing in the manufacture of top-quality Aircraft Aluminum Sheets. With over a decade of experience and experience, the company has a blend of modern technology and stringent quality assurance as an industry-leading aircraft aluminum sheet manufacturer to produce products that meet the highest standards.

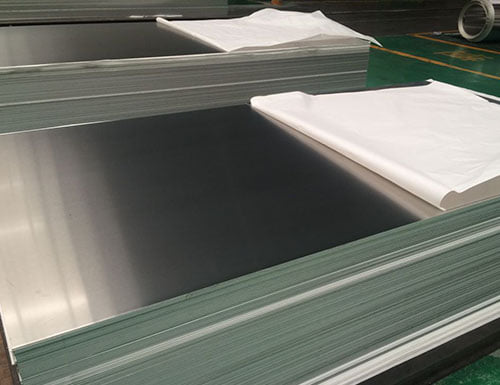

Lanren offers a selection of aircraft-specific alloys applications:

| Alloy Series | Key Properties | Typical Applications in Aviation | Weight Reduction Benefit Compared to Steel |

| 2024 | High strength, good fatigue resistance | Wing structures, fuselage frames | 30-40% weight reduction in critical components |

| 7075 | Ultra-high strength, excellent toughness | Landing gear parts, structural supports | 25-35% weight reduction in heavy-load areas |

| 6061 | Good formability, corrosion resistance | Interior components, cabin panels | 40-50% weight reduction in non-structural parts |

Choosing Lanren Aluminium means partnering with a company that is dedicated to achieving excellence. Quality control measures are rigorous to ensure that every sheet is in compliance with the aviation standards. Specific solutions are tailored to meet specific weight reduction objectives and a strong focus on the latest technology ensures that Lanren in the forefront in the field of aerospace material design.

Related Products