How to Choose Aluminum Discs for Stamping?

Aluminium discs find applications in the stamping of metals in automotive, aerospace, electronics, and cookware industries. Choosing proper aluminium discs guarantees quality, durability, and precision in the stamped parts. This aluminium stencil guide discusses some of the important factors to optimise performance and prevent recurring defects when piercing aluminium discs.

Why Aluminum Discs Can Be Used for Stamping

Due to the lightweight nature of aluminium and its resistance to corrosion, aluminium discs are heavily utilised in metal stamping. This, in conjunction with the disc’s ability to hold precise shapes, makes its use ideal in the manufacturing of cookware, traffic signs, automotive panels, and industrial parts. Unlike other metals, aluminium has a better ratio of strength and flexibility. Thus, it deep draws and complex stamps easily without the risk of cracking or warping.

Commonly used alloys, such as 1050, 1060, 3003, and 5052, are tailored to have different strength and conductivity for different use cases. For example, 1050 and 1060 have higher conductivity making them more useful in cookware. On the other hand, 5052 is more helpful in parts which require better strength and fatigue resistance.

Aluminium and its alloys have the advantage of higher oxidisation, increasing durability, which improves anodising or painting. Combined with its high recyclability and low manufacturing costs, aluminium has become a go-to in mass manufacturing.

Given the wide-ranging alloys and high resiliency when metal stamping, it is highly dependable when dealing with both simple and complex designs.

Selection Criteria for Choose Aluminum Discs for Stamping

The quality of aluminium discs will directly impact the finishing quality of the product, the defects on it, and the production efficiency. Therefore, it is important to select aluminium discs carefully. Below, we will summarise the most important elements for consideration while selecting aluminium discs:

Identify the Product Goals and Requirements

Set the goals and quantify the performance measures on which the stamped product will be evaluated. For instance:

- Food-safe materials which are highly efficient for thermal heat conduction, for cookware.

- Automotive components which are tough and fatigue resistant along with good corrosion protection.

- Products for lighting and signage require high reflectivity combined with aesthetics for the surface quality.

The alloy, temper, and finish are guided by the functional and environmental needs.

Consider The Alloy of Aluminium Used

Different grades of aluminium have different chemical, mechanical, and physical properties, especially when stamped. For instance:

- 1050, 1060, 1100: All high-purity aluminium with excellent ductility and corrosion resistance, deep drawing and household items.

- 3003: Better strength and workability. Used in cooking utensils, roofing, and signage.

- 5052: Considered to be high strength, this alloy has excellent fatigue resistance used in automotive and marine parts.

Choosing the right alloy will ensure the aluminium disc withstands the stress of the stamping.

Pick the Right Thickness and Radius

The thickness and radius of the aluminium disc affect formability and ease of equipment use. It is easier to form thin discs, but they may be weak. Thicker discs are more durable but may need increased stamping force.

- Common thickness range: 0.5 mm to 6.0 mm

- Standard diameters: 50 mm to 1000 mm or custom size available upon request

Adherence to precise specifications decreases material scrap and increases production efficiency.

Reliability & Certifications of the Supplier

The reliability of the supplier of aluminium discs is as critical as the material selection itself. A supplier with the following features is preferable:

- Possesses ISO 9001, ASTM, or equivalent certifications

- Maintains material traceability and QC report consistency

- Is known for supplying stamping aluminium grade material

- Supports custom requests, rapid turnarounds, and technical guidance

Reliable suppliers not only deliver high-quality products but also help avoid production downtime and defects.

Where to Find Quality Aluminum Discs Supplier

Finding aluminium disc suppliers guarantees consistency in production batches, quality services, and time-efficient deliveries. A reliable supplier guarantees all of the required alloy and dimensional specifications alongside providing full technical support and quality assurance throughout the entire process.

Verify supplier companies using the following features:

- Compliance with ISO 9001, SGS, BSI, or ASTM standards

- Experience in aluminium disc production for stamping, deep drawing and spinning, and other adjunct services.

- Flexibility in providing custom features like: dimensions, alloys, and tempers.

- Established clientele overseas with reputable customer reviews.

- Dependable logistics and lead time support.

A company recognised and trusted in this area is Lanren Aluminium, a manufacturer for over 20 years in the business of producing aluminium discs and circles for stamping and cookware production. Lanren has a broad list of aluminium alloys, like 1050, 1060, 3003, and 5052, which can be used in both shallow and deep drawing applications. They are known for their products with excellent surface quality, uniform thickness, and tight tolerances which are required in shallow and deep drawing processes.

Lanren offers tailored assistance and quick, reliable service for large-scale industrial phone applications and for specialised bespoke products. Customised to meet specific needs, every disc goes through advanced production line processes and meets rigorous international standards.

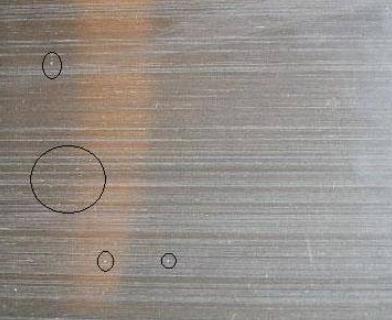

Common Aluminum Discs Stamping Defects & How to Avoid Them

Defects in stamping may occur due to incorrectly optimised material, tooling, and even process settings, regardless of the chosen quality of aluminium discs. Understanding these issues—and how to mitigate them—is pivotal for safeguarding product quality alongside reducing waste.

Cracking

In an effort to deep draw, cracks are prone to form from the aluminium alloy or temper being overly unforgiving. Using softer tempers O or H24 whilst ensuring elongation in the material supports avoiding this issue.

Wrinkling

The folds are formed as a result of low to zero, or uneven blank holder force. Fine corrective adjustments to the die and application of adequate holding pressure guarantee flat surfaces, thus the prevention of folds.

Surface Scratches

The most probable causes of scratches are die faces substituted for discs or surface portions of rough discs. Employing aluminium discs that are procured from reliable suppliers ensures a smooth and clean finish whilst regulating stamping tools for cleanliness prevents the issue.

Burrs and uneven edges

Cutting tools that are damaged or out of alignment are the root causes of uneven edges and burrs. Ensure that your cutting equipment is sharp and well calibrated to your set standards alongside the industry standards for pristine edges.

Stamping efficiency and overall accuracy are improved whilst defects are greatly diminished through proper control of tooling conditions and the selection of aluminium discs.

Selecting aluminium discs for stamping isn’t as simple as picking an alloy or size – there’s an application study, supplier evaluation, and performance optimisation to handle first. Paying attention to alloy composition, disc thickness, surface finish, and certifications will enhance product quality and minimise manufacturing defects.

Make sure to spend time sourcing a reliable aluminium disc supplier, and contact material engineers if needed. Those efforts will help achieve consistency and high quality in the stamping results.

Related Products