What are the Types of Aluminium Coating & Their Applications?

Why Coating on Aluminium?

With many years of experience in the manufacturing of aluminium products, I can affirm that even though there is natural corrosion resistance from the material, very often surface protection is necessary to meet the long-term performance requirements of many uses. Coating on aluminium not only improves its resistance to environmental factors such as humidity, salt, and UV exposure but also enhances mechanical durability, aesthetic appeal, and even thermal performance.

Uncoated aluminium in industrial applications may be subjected to surface oxidation or wear, which, over time, compromises the quality of products. Coatings present a tailored solution by which we can optimise aluminium in certain environments. Let’s see some common types of aluminium coatings.

Common Types of Aluminium Coating

Coatings on aluminium are necessary for protection, performance, and appearance. Many methods exist, but for their versatility and effectiveness, the following five are most widely used in the industry.

Anodising

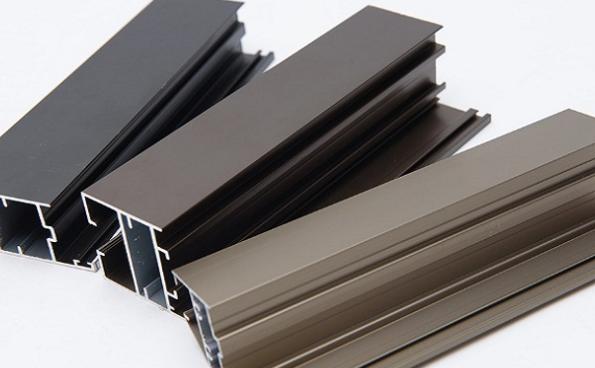

Anodising is an electrochemical method of thickening the aluminium’s natural oxide layer. It provides more hardening, corrosion and wear resistance. The anodising process provides colour finishes that are more visible and integrated than a coating, making it less likely to peel and flake in areas with more wear and exposure.

Anodised aluminium is recommended for architectural panels, consumer electronic casings, and automotive trim appliances due to their exposure, wear, and aesthetic concerns.

Powder Coating

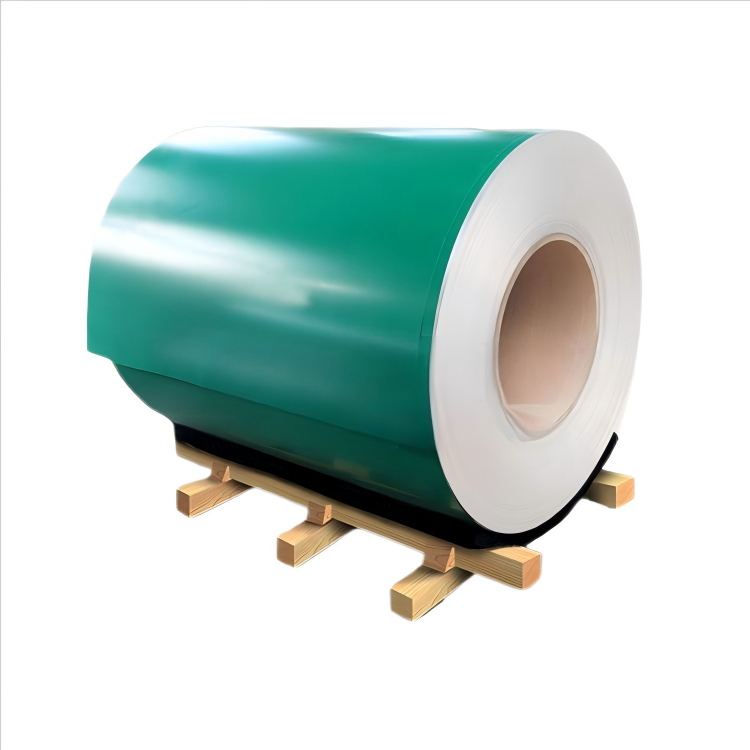

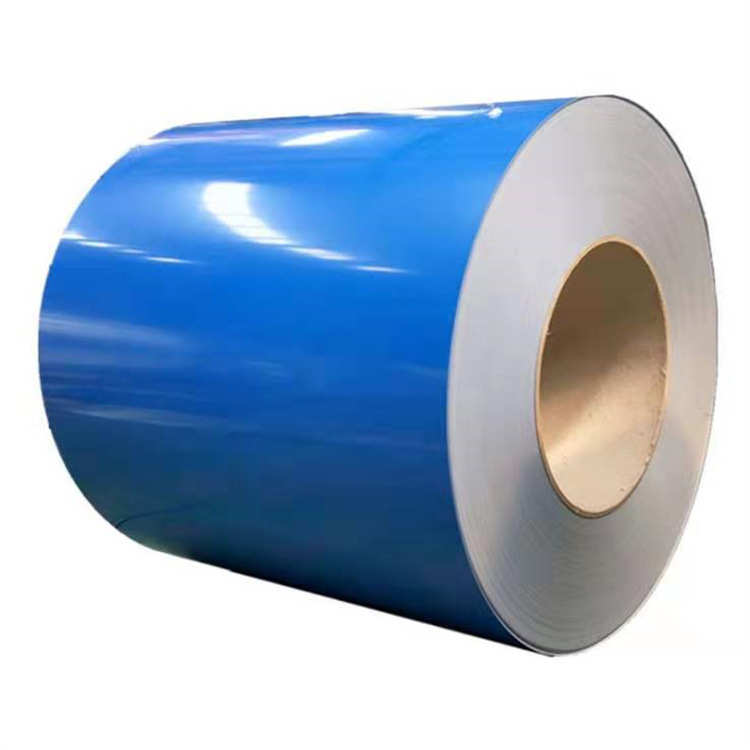

Powder coating is an electrostatic dry finishing process where a fine powder is applied to the surface of the aluminium and then heated to the point of curing into a solid, continuous layer. The coating is very protective against chipping, fading, and weathering. This makes powder coating aluminium ideal for outdoor and weather-exposed equipment and for industrial applications where weather resistance is a concern.

Powder coating is very versatile due to the wide range of textures and colours that are available and is commonly used on mill finish aluminium furniture, structural frameworks, and machine housings designed to provide long-lasting protection with minimal maintenance.

Electroplating

To improve the visual qualities of aluminium and add corrosion and wear resistance by plating it with metals like nickel, chromium, or copper, electroplating uses electric currents to coat the aluminium with metals, giving it a shiny new appearance.

Electroplating aluminium is best suited for precision and aesthetic sectors such as aerospace parts, electrical rollers, and decorative electrical trim.

Hot-Dip Aluminium Coating

Also called aluminising, hot-dip aluminium coating is when aluminium is, more commonly, steel, and is submerged into molten aluminium. This process develops a thick coating, then metallurgically bonds. This coating protects against corrosion and also withstands extreme heat. This makes hot-dip aluminium coating suitable for use in industrial pipelines, heat exchangers, roofing materials, as well as other materials set in difficult conditions. Hot-dip coatings also promise to protect industrial tools for a long time, to reduce the amount of maintenance required, as well as to increase the lifespan of the component being used.

Aluminised Paint/Spray Coating

With this method, a fine layer of aluminium-infused paint or spray is deposited on the surface of aluminium. This coating gives a certain degree of corrosion protection, reflects heat, and can serve as a temporary protection layer while the item is being transported or installed.

This method is commonly used on automotive parts, HVAC equipment, and machinery that need surface protection or heat reflection, and where the expense of other, more stringent coating methods is economically unjustified. Aluminised paint is an economically viable option that provides an excellent compromise between functionality and the visual appearance of the surface.

Applications for Different Aluminium Coating Types

As we know the types of aluminium coating, the next step is to learn their applications. Here I use a table to summarise it:

| Aluminium Coating Type | Key Applications | Industry Use & Benefits |

| Anodizing | Provides surface hardness, scratch resistance, and long-lasting colour stability; ideal for visible surfaces requiring both aesthetics and durability | Decorative hardware, aerospace components, and electrical connectors |

| Powder Coating | Outdoor furniture, machinery housings, transportation equipment | Thick, durable layer protects against abrasion, UV, and weathering; suited for harsh environments and heavy-duty applications |

| Electroplating | Aluminised Paint / Spray Coating | Enhances corrosion and wear resistance while maintaining a polished finish; suitable for precision parts and visually demanding applications |

| Hot-Dip Aluminium Coating | Pipelines, structural steel, HVAC systems | Excellent corrosion and high-temperature resistance; widely used in industrial and infrastructure projects exposed to harsh conditions |

| Aluminized Paint / Spray Coating | Automotive underbodies, ductwork, factory machinery | Reflective and moderately corrosion-resistant; useful for heat reflection or temporary protection during operation or transportation |

Varied aluminium coatings fulfil different operational requirements. There is no one-size-fits-all coating type. Environmental conditions, product use, and maintenance obligations need to be aligned to optimise coatings. This will help improve product durability, lower costs in the long run, and enhance the product’s overall value.

How do You Choose the Suitable Aluminium Coating Types?

Choosing the right aluminium coating is a critical decision with a direct bearing on product performance, service life, and maintenance needs. In our experience as a manufacturer, this choice should be guided by a combination of environmental, mechanical, and functional criteria, rather than cost alone.

- First, consider the environment in which the aluminium component will operate. Coastal or industrial areas with high humidity, salt, or chemical exposure demand coatings with strong corrosion resistance, such as anodising or hot-dip aluminium coatings. In the event of exposure to direct sunlight or rough weather, powder coating offers excellent UV and abrasion protection.

- Secondly, analyse mechanical and operational requirements. Parts operating under friction, impact, or heavy wear fare well from the increased hardness and surface longevity afforded by electroplating and powder coating, respectively. Conversely, those parts requiring just a moderate level of protection with added reflectivity, such as HVAC ducts or automotive panels, may do quite well using aluminised paint or spray coatings.

- Third, aesthetic and functional stipulations have to be considered. While anodising provides colour options along with wear resistance, it is fitting for visible architectural or consumer products. Electroplating yields a smooth, metallic finish apt for high-end decorative uses.

- Also, think about maintenance and how long it will last. While some coatings cost more at the start, they can save money in the long run due to lowering maintenance costs. Take care in how you balance the climate, mechanical stress, looking at it, and how much money you can spend, so that you, the manufacturer, can choose the aluminium coating that will give you the best performance and the most value over time.

Final Thought

Aluminium Coatings are the key to serviceability, longevity, performance, and overall cost of the product. Choosing the right coating is crucial not only for protecting the investment but for the finishing of the product and achieving the demanding environmental or mechanical attributes.

With experience as a manufacturer of aluminium, we understand the difficulty of choosing the best coating for every application. From anodising and Powder Coating to hot dip as well as electroplating, we supply tailor-made aluminium products fulfilling functional and decorative purposes. By combining quality Aeronautical aluminium with the right surface finishing treatment, we are able to help our clients achieve transparency, adhesion, durability, and remarkable appearances.

For any requirements, feel free to contact us!

Related Products