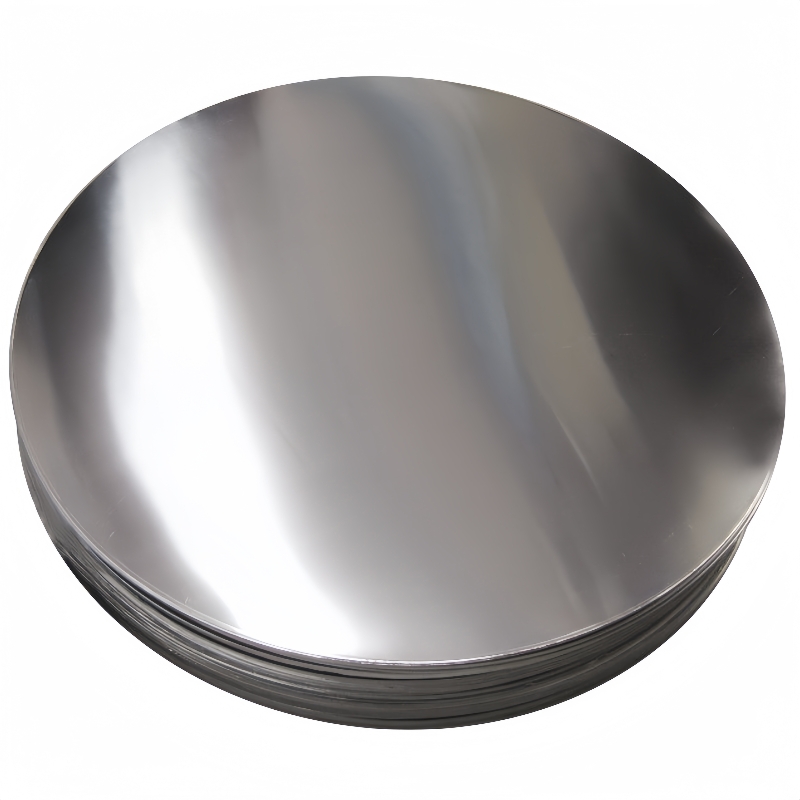

How to Calculate Aluminium Circle Price Per Kg?

The aluminium circle price per kg is influenced by various factors, including the current market price of aluminium ingots, processing costs, size, thickness, and surface finish. Understanding these elements helps customers assess whether the quoted price is fair and competitive. Learn how to calculate aluminium circle pricing, tips to secure the best wholesale rates, and where to find reliable suppliers offering top value.

Key Factors Affecting Aluminium Circle Price Per Kg

In order to understand the price of aluminum circle, you need to take into account many contributory factors. Three main aspects have a significant impact on the cost per kilogram. These are the global aluminum ingot cost, the manufacturing and processing cost along with the dimension and design of the circle. Next we will provide a more detailed look at the individual aspects that affect each

Aluminium Ingot Market Price

The primary element of price of aluminium circles is the cost of the raw metal, namely aluminium ingots. They’re sold as commodities globally, and have price fluctuations that are based upon demand and supply economic conditions, geopolitical developments as well as general economic trends. In particular, a rise in demands from the construction and automotive sectors will increase prices for aluminium. Also, any disruptions to mining and smelting activities, like the ones caused by environmental regulations or energy scares–may decrease production and cause prices to rise. Since aluminium circles are made using rolled sheets of aluminium made from the ingots, any variation of the ingot’s price base directly affects the final cost per kilo.

Manufacturing and Processing Costs

Beyond the raw materials, expense of transforming aluminum ingots into finished circular shapes is a major factor in the expense. This involves cold and hot rolling and cutting, annealing, stamping, as well as other procedures. The degree of complexity in the manufacturing process is determined by the specifications required. For example, circular shapes which require a smooth surface as well as tight tolerances or specific mechanical characteristics are subject to more intense process, which will increase expenses. In addition, the cost of labor along with equipment maintenance and energy usage add to the total cost of processing, particularly those in areas that have significant labor or utility costs.

Size, Thickness, and Alloy Type

Physical dimensions and the alloy composition of an aluminium circle play a major role in determining the price. The larger and more slender diameters of circles make use of more raw material and, consequently, increase the weight and price per gram. Furthermore, different alloys (such 1050, 1060 or 3003) are different in their features and cost. Certain alloys are resistant to corrosion or are better suited to deep drawing. These could require extra process or better-quality raw materials which can impact the price per kilogram.

Tips for Getting the Best Wholesale Aluminium Circle Price

To get the best price on wholesale aluminum circles takes more than comparing figures. It is about the strategic selection of suppliers, understanding their capabilities, and making the most of bargaining opportunities. Below are 5 essential suggestions for getting the lowest price possible:

1. Buy in Bulk to Maximize Discounts

Quantity plays a significant factor in the pricing. The majority of suppliers offer prices that are based on quantities. The larger the order, the lower the cost per kilogram. Big orders can cut down on handling, logistics, and setup costs for production, and are typically willing to share with you as savings. Making your purchases in bigger batch sizes can dramatically lower the cost per unit.

2. Check the Supplier’s Manufacturing Capabilities

Working directly with producers instead of intermediaries can save you from price increases. Furthermore, those who have in-house production facilities are able to provide more control over the quality of their products and prices. Find out if the provider manages processes (cutting or annealing) by itself or outsources the work. This impacts both the cost and the speed of delivery.

3. Negotiate Long-Term Supply Contracts

If you’re in constant demand, you might want to negotiate the possibility of a contract for supply over the long term. A lot of suppliers will reduce prices in ongoing collaborations, because it assures an ongoing operation. A lock-in price can protect from market fluctuations.

4. Get Quotes from Multiple Suppliers

Request quotes from a variety of trustworthy suppliers, local and international. The comparison of quotes not only provides you an understanding of what is available, but can also help you stand out in negotiations. It is important to give similar requirements (alloy kind, size of the piece, amount, and final) for a precise comparison.

5. Time Your Purchase Wisely

Pay attention to the aluminum ingot market developments. Prices fluctuate based on fluctuations in the global economy or demand during the season. The purchase of a metal when its base price drops, even just a bit, could result in significant savings, particularly on big purchases.

If you follow these guidelines by following these tips, you will be able to secure top-quality aluminum circles for the most affordable wholesale costs.

Where to Find Best Price Wholesale Aluminium Circle

The best cost for aluminium circles wholesale requires finding reliable and effective manufacturers. There are a lot of options on the market globally however, knowing where to look and who to go with can have a significant impact on price, quality as well as delivery time reliability.

1. Online B2B Marketplaces

Websites such as Alibaba, Made-in-China, and Global Sources list numerous aluminium circle manufacturers. They allow easy comparison of pricing, specifications and customer feedback. But, it’s crucial to confirm the credibility of a supplier and ask for samples prior to making large purchases.

2. Direct to Manufacturers

Directly from aluminum circles manufacturers is usually the best option for cost savings. Manufacturers are able to offer factory pricing and better customization options and quicker production times. The most trusted source are Lanren Aluminium, a well-established aluminum circle manufacturer with more than twenty years of expertise. Lanren is a specialist in the production of premium aluminium discs made of various sizes and alloys. They are extensively utilized in lighting, cookware and other industrial applications.

3. Local Distributors and Trade Shows

If you’re looking to source locally local metal distributors typically have aluminum circles on hand or create special orders. Going to trade fairs or industry events is an additional way to get in touch with suppliers who are certified as well as negotiate prices, and build long-term relations.

If you’re looking locally or globally using a trusted manufacturer such as Lanren Aluminium ensures you get the most competitive price as well as quality and service in your aluminium circles wholesale demands.

Contact us today to receive our most current quotation!

Related Products