1100 Aluminum Plate

- Width: 20.0MM – 2,600MM or as required

- Length: 2M, 4M, 6M, or customized as required

- Surface: Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc.

- Finish: Mill, Customer-specific finish

- Lead Time: Within 7-15 days after receiving the deposit.

Our 1100 Aluminum Plate is a top-grade material in the 1000 series of aluminum alloys with a minimum of 99% pure aluminum content. This makes it the most highly alloyed and most mechanically strong in its series. It is famous for its usage in rivet production, and its light alloy properties make the 1100 aluminum plate offer excellent electrical and thermal conductivity, with corrosion resistance and formability. While it can be enhanced through cold working to enhance strength, note that it does not respond to heat treatment to enhance its properties.

Being a factory committed to performance and quality, we pride ourselves in providing this resilient and dynamic material to meet the diverse demands of our customers.

Specifications of 1100 Aluminum Plate

| Number | 1100 |

| Brand Name | Lanren |

| Temper | O, H14, H24, H18 |

| Thickness | 0.20MM – 6.0MM or as required |

| Standard | GB/T 3880, ASTM B209 |

| Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. |

| Lead Time | Within 7-15 days after receiving deposit |

| Payment Terms | TT, 100% LC, Western Union |

| MOQ | 1 Ton, please contact us for special needs. |

| Tolerance | ±1% |

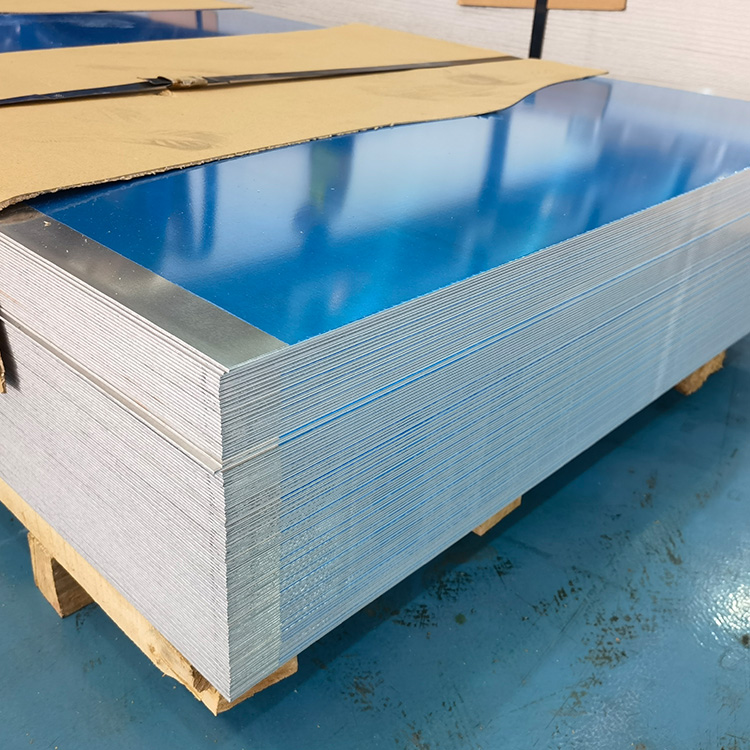

| Packaging | Export standard packaging: wooden pallet + cardboard + steel bar fixed |

1100 Aluminium Plate Equivalent

| UNS | USA | Japan | France | ISO |

| A91100 | AA1100 | JIS A1100P | NF 1100 | Al 99.0 Cu. |

1100 Aluminium Plate Chemical Properties

| Element | Fe | Si | Mg | Mn | Cu | Zn | Ti | Cr | Others | AI |

| 1100 (min) | 0.35% | 0.25% | 0.01% | 0.01% | 0.05% | 0.01% | 0.02% | Trace | 0.05% (each) | 99.60% |

| 1100 (max) | 0.50% | 0.35% | 0.03% | 0.05% | 0.20% | 0.05% | 0.03% | Trace | 0.15% (total) | Remainder |

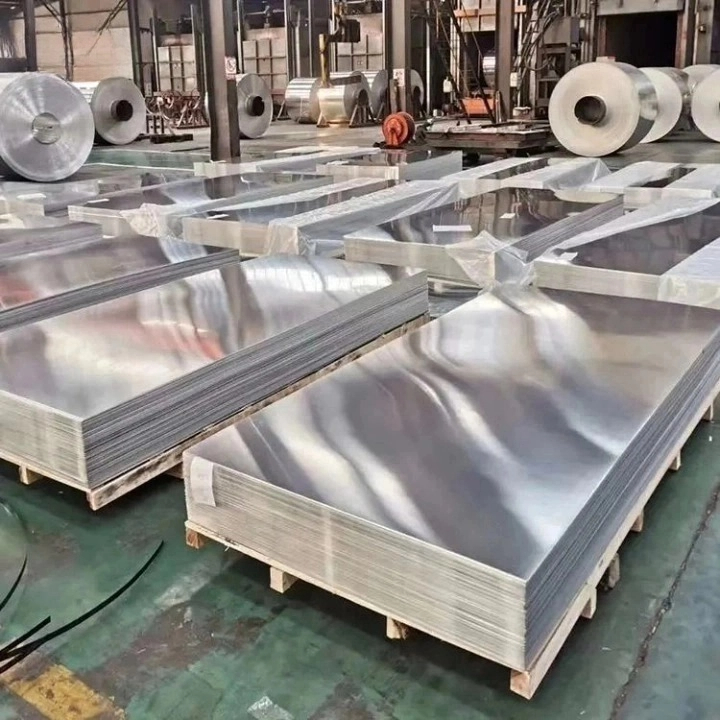

Warehouse Display

Advantages of Lanren 1100 Aluminum Plate

With 1100 aluminum having at least 99% purity, it is the most refined aluminum grade available for practical applications. - It is most difficult to fracture under extreme tension or torque, where it can be bent, stretched or twisted effortlessly into complex shapes.

- 1100 aluminum is particularly advantageous because it is naturally resistant to corrosion which allows it to endure harsh environments and climates without any additional protective measures.

- This allows it to serve as a component for heat sinks or other parts requiring electricity to be conducted as it outperforms many other metals.

- Due to the ease of using several welding methods, 1100 aluminum can seamlessly integrate into existing assembly lines which requires no additional alterations.

- It is true that the alloy cannot be made stronger with the processes of heating and quenching, however, rolling or stamping into shape will increase the strength.

- The ability to effortlessly recycle 1100 aluminum plates increases cost-effectiveness in comparison to other materials with the added benefit of being readily available.

- 1100 aluminum plates are a cost-effective solution because they can be remelted to create new parts without any loss to quality which in turn reduces energy waste.

- Its ability to be polished to a mirror finish makes it a popular selection for facades. Additionally, it reduces the overall weight of the product. This is a major advantage for delivery trucks, airplanes, and rockets seeking to conserve fuel and reduce expenses.

Application Scenarios of 1100 Aluminum Plate

- The 1100 aluminum plate is utilized in several industries because it is thermally and electrically conductive, lightweight, low-density, and resistant to corrosion. It has applications in the food and chemical industries for the fabrication of process tanks and equipment. In construction, it is used for wall cladding, roofing, ceilings, and architectural decorations due to its high reflectivity and easy of working with.

- The 1100 aluminum is useful in the electronics industry for heat sinks, PCB baseboards, and electronic packaging because of high thermal and electrical conductivity. It is used in the automotive industry body panels and components to reduce the weight of the vehicle to improve the fuel economy.

- Another sector that 1100 aluminum serves is the packaging and lighting industry which includes reflectors, decorative components, and bottle caps. It is used in thermal management systems such as heat exchangers and radiators.

- 1100 aluminum is employed in decorative as well as other general manufacturing such as in signage, license plates, rivets, kitchenware, cookware, and other hardware. Why this alloy is employed in multiple industries is due to its easy fabrication and adaptability.

Why Choose Lanren Aluminum As Your 1100 Aluminum Plate Supplier?

- Since 2008, Lanren Aluminum gained a lot of trust in the aluminum market and business due to our unwavering dependable service and high-quality offerings.

- As a one-stop manufactuer, Lanren Aluminum offers 1100 aluminum plates, coils, circles, composites, cookware and other aluminum products, serving industrial and commercial needs with agility. They assist and meet the requirements of both the aluminum.

- Lanren Aluminum’s 50 thousand square meter facility and the more than 300 professionals in the firm, coupled with reliability, precision and trust showcase the gained confidence in the industry with the quality and trustworthiness the firm has in production.

- Under the “quality and customer first” slogan, Lanren Aluminum offers unmatched competitive prices, OEM customization, responsive after sales service, unyielding support, and unwavering support. All of which strengthens the standing of the firm in over 80 countries.

- Lanren Aluminum is equipped with notable accolades and certifications which strengthens the reputation of the company alongside the transparency and trust, hence granting the clients trust to work with the firm and use the operations, values and the team.

- Unlike more of the industry, Lanren Aluminum offer customization and embrace the needs of the clients which showcases the company’s appeal and strengthens the standing as trusted partner for unbroken collaboration.

Experience unmatched confidence, efficacy, and extensive development with Lanren Aluminum, who welcomes clients to tour our workshops, nurturing collaborations and partnership ventures.