3003 is a standard aluminum grade. 3003 aluminum sheet possesses good machinability, moderate strength, and reasonable corrosion resistance, making it a versatile and practical product used in various industries and applications.

Compared to 1050 type aluminum, it has superior mechanical properties. It is easy to process, and like all aluminum materials, it weighs less than one-third of steel and offers better corrosion resistance.

3003 Aluminium Plate Specifications

| Number | 3003 |

| Brand Name | Lanren |

| Temper | HO, H12, H14, H16, H18, H19, H22, h24, h26, H28, H112, etc. |

| Tolerance | ±1% |

| Standards | ASTM B209 / ASME SB209 |

| Thickness | 0.1MM – 200MM or customer required |

| Width | Within 7-15 days after receiving the deposit |

| Length | 2000MM, 2440MM, 6000MM or as required |

| Surface | Coated, Embossed, Brushed, polished, Anodized, etc |

| Finish | Perforated, cutting special size, Doing flatness, Surface treatment,etc |

| Lead Time | 100MM – 200MM, according to the customer’s requirements |

| Payment Terms | TT, 100% LC, Western Union |

| MOQ | 1 Ton, please contact us for special needs |

| OEM service | Perforated, cutting special size, Doing flatness, Surface treatment, etc |

| Packaging | Export standard packaging: wooden pallet + cardboard + steel bar fixed |

3003 Aluminium Plate Mechanical Properties

| Property | Metric | Imperial |

| Tensile strength | 130 MPa | 18855 psi |

| Yield strength | 125 MPa | 18130 psi |

| Shear strength | 83 MPa | 12039 psi |

| Fatigue strength | 55 MPa | 7977 psi |

| Elastic modulus | 70-80 GPa | 10153-11603 ksi |

| Poisson’s ratio | 0.33 | 0.33 |

| Elongation | 10% | 10% |

| Hardness | 35 | 35 |

3003 Aluminium Plate Chemical Properties

| Element | Fe | Si | Mn | Cu | Mg | Zn | Ti | Cr | Others-Each | Others-Total | Al Min |

| 3003 | 0.7% | 0.6% | 1.0 – 1.5% | 0.05 – 0.20% | – | – | – | – | 0.05% | 0.15% | Remainder |

Advantages of 3003 Aluminium Plate

The 3003 aluminium plate has outstanding formability, which permits shaping and sizing processes, thereby meeting the needs of a wide array of customers.

The 3003 aluminium plate and radiator have good conductivity and are ideal for coolant and heating dischargers for cooling systems. In addition, the aluminum plate has good conductivity, which is good for electronic devices and power transmission systems.

The 3003 aluminum plate is much lighter than other metals. For this reason, it is applied extensively in the aerospace and automobile industries, which prioritize weight.

The 3003 aluminum plate is available in a wide variety of standard sizes and custom dimensions for a specific project requirement. This adaptability enables us to fully satisfy our customers’ expectations.

The aluminum plate 3003 is committed to being high in strength and corrosion resistant while being easy to work with. This makes the aluminum plate ideal for the aluminum industry and applications.

Application of 3003 Aluminium Plate

The applications for Aluminium 3003 Plate in different industries and sectors include Construction aluminum plates, which provide solutions for building exteriors, framing systems, garage doors, partition siding, as well as gutters.

- The ease of working with aluminum alloys enables people to give them different shapes, thus making them suitable for use in components such as decorative trims and architectural structures.

- People in the automotive industry use aluminum 3003 to manufacture fuel tanks and heat exchangers because of the alloy’s ability to endure shear and compressive forces.

- Engineers in the chemical industry use 3003 aluminum plates and employ them in making tanks that store chemicals, and equipment, because of their ability to withstand corrosive chemicals.

- Aluminium 3003 shapes are ideal with Ductwork. Thus, they are commonly used and applied in the construction of air ducts.

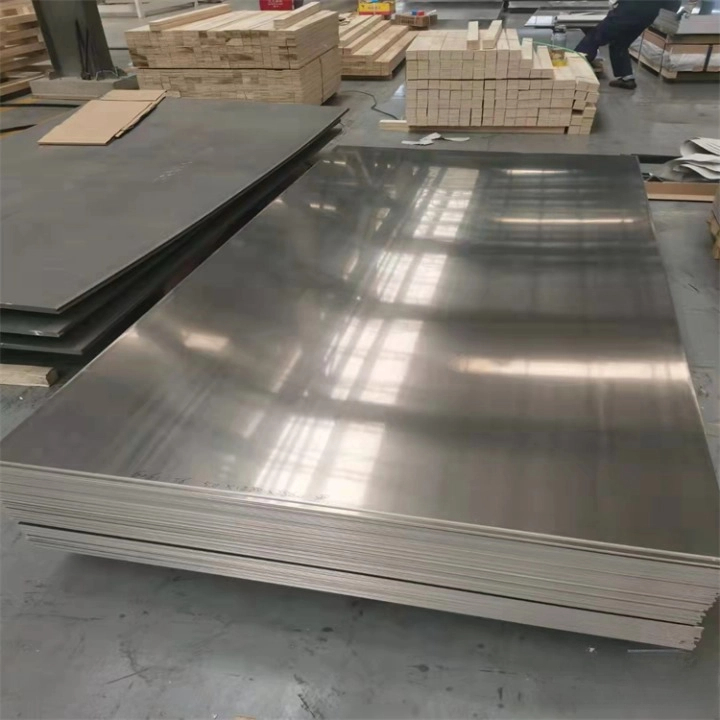

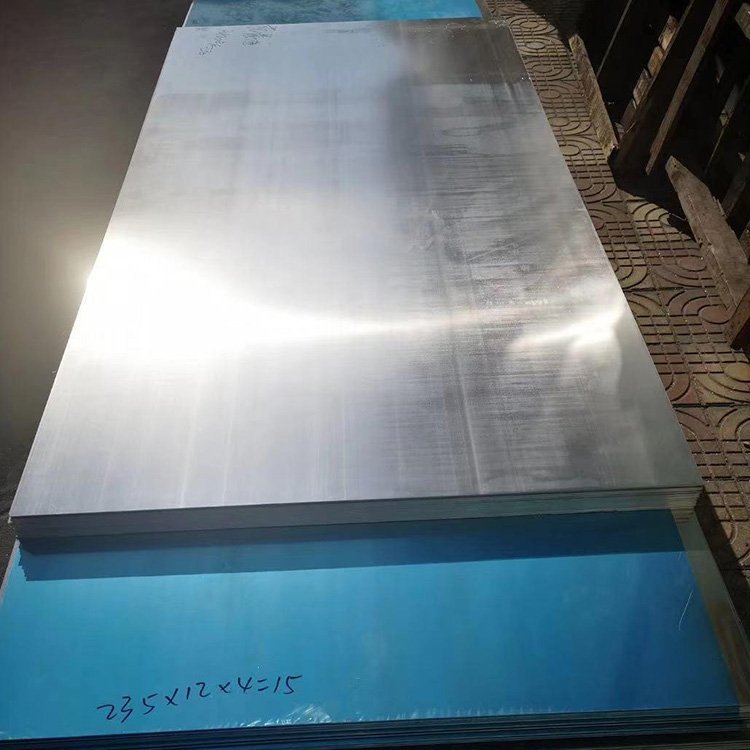

Warehouse Display

FAQs about 3003 Aluminium Plate

- Can a 3003 Aluminium Plate be welded or formed?

Yes. 3003 Aluminium Plate welds easily using TIG or MIG methods and can be formed, bent, or rolled without cracking, making it ideal for custom shapes and fabrication. - How thick is the 3003 Aluminium Plate available?

It is available in a wide range of thicknesses, generally from 0.5 mm to 200 mm, depending on the manufacturer and application requirements. - What is the difference between 3003 and 5052 Aluminium Plates?

3003 is easier to form and work with but has lower strength. 5052 is stronger and more resistant to saltwater corrosion, making it suitable for marine applications. - Can a 3003 Aluminium Plate be anodised?

Yes. 3003 can be anodised, but the finish may be less uniform compared to 5000-series aluminium due to its higher manganese content. - What surface finishes are available for 3003 Aluminium Plate?

Common finishes include mill finish, brushed, polished, or painted coatings, depending on aesthetic and protective requirements.