Chongqing Lanren Aluminium Co., Ltd is a renowned manufacturing company that produces, exports, and supplies aluminum circles. We design these products as per international and national standards and norms. We can supply all kinds of Pure Grade Aluminum Circle. It can be customized and manufactured to your requirements.

Blank aluminum discs are available in CC and DC materials. Common alloys are 1, 3, and 5 series.

Features of Blank Aluminum Circle

According to different processing techniques, it is divided into hot rolling and cast rolling.

Compared with cast-rolled blanks, hot-rolled blanks have fewer impurities, so their anti-corrosion properties are much stronger, especially against seawater.

At the same time, due to the recrystallization process, its internal structure is more stable and uniform, and the formed aluminum material has better performance and ductility.

The performance is better than that of cast and rolled materials. The surface is brighter. Compared with the hot rolling process, casting and rolling do not require slag removal and surface milling.

Heating, hot rolling, and other processing processes, from which casting and rolling are also commonly known as cold rolling.

- DC quality: Deep drawing quality, Less Scrap, suitable for making cookware.

- CC quality: good surface, suitable for the lighting industry.

1 Series Aluminum Circle:

- 1. The aluminum content of aluminum circles is above 99%, with good corrosion resistance and excellent formability.

- 2. The reflectivity of 1 series aluminum circles is higher than that of other alloy series.

- 3. Stable performance, surface anodization can be carried out, and the process is mature.

3 Series Aluminum Circle:

- 1. 3 series aluminum circles have stable and excellent formability and high strength.

- 2. High elongation, widely suitable for deep drawing process.

- 3. The grain size is high, showing a clean luster, and the aluminum disc has high reflectivity.

5 Series Aluminum Circle:

- 1. The material density is low and the weight of the finished product is small.

- 2. The grain size is higher and the surface effect of the aluminum wafer is good.

- 3. High tensile strength and elongation, high fatigue strength, particularly strong seawater resistance, and good welding performance.

8 Series Aluminum Circle:

- 1. Excellent anodizing effect.

- 2. Stable performance indicates high quality.

Specification of Blank Aluminum Circle

| Place of Origin | CHINA |

| Brand Name | Lanren |

| Product name | Aluminum circle |

| Temper | O-H112 |

| Alloy Or Not | Is Alloy |

| Diameter | 20MM-1380MM |

| Thickness | 0.4mm-10mm |

| Grade | 1,3,5,8 alloy series |

| Technology | Hot rolled (DC)& Cold rolling (CC) |

| Packing | Export standard packaging: wooden pallet + cardboard + steel bar fixed |

| Application | Stock pots/ electric skillets/sports lighting/tea kettles |

| Certification | ISO9001/SGS/FDA |

Advantages of Blank Aluminum Circle

The surface performance of the aluminum circle is good, ensuring no obvious scratches, oil stains, oxidation, black spots, etc.

Aluminum discs are light in weight and have strong corrosion resistance. They have low density and are lightweight, so they are widely used in transportation manufacturing industries such as aviation, automobiles, and ships.

The quality of aluminum discs complies with the ISO 9001 quality management system.

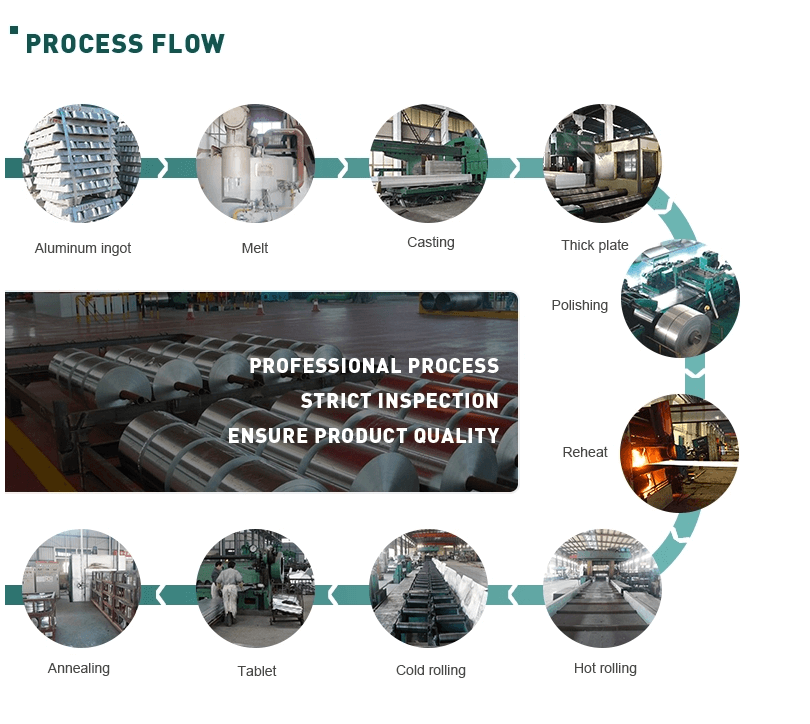

Product Process of Blank Aluminum Circle

We have CC and DC materials, this is the difference between DC and CC material:

- Hot rolling process( Direct Cast rolling-DC): Aluminium ingot → Melting casting → Slag removal → Milling surface → Heating → Hot rolling → Cold rolling → Finishing rolling → Cut into Discs

- Casting and rolling process(Continuous Casting Rolling-CC): Melting casting → Crystal cooling forming → Cold rolling → Finishing rolling → Cut into Discs

QC(Quality Control)

Why Choose Lanren?

Our aluminum round cookware enjoys a good reputation among customers for its high quality and competitive prices and has won high appreciation from customers for its excellent workmanship and professional capabilities. Quality complies with the ISO 9001 quality management system.

Packing&Delivery of Blank Aluminum Circle

1. Pallet packaging: Place the aluminum round sheet neatly on the pallet, and then fix it with winding film or packing tape to prevent the aluminum round sheet from moving during transportation. Pallet packaging is easy to handle load and unload and is suitable for the transportation of large quantities of aluminum discs.

2. Wooden box packaging: For some special specifications or higher requirements of aluminum discs, they can be packed in wooden cases. The wooden box has high strength and stability, which can better protect the aluminum disc. In the wooden box, materials such as foam and air cushion film can be used for filling and fixing. When selecting the packaging method, it is necessary to consider the specifications, quantity, transportation distance, storage environment, and other factors to ensure that the aluminum discs are not damaged during transportation and storage.

FAQ

Q1: Are you a trading company or manufacturer?

A: We are a manufacturer.

Q2: How can we guarantee quality?

A: Always a pre-production sample before mass production; Always final Inspection before shipment.

Q3: What can you buy from us?

A: Aluminum Sheets, Aluminum Coils, Aluminum Strips, Aluminum Products.

Q4: Why should you buy from us not from other suppliers?

A: Our company has 15 years of experience, free samples and small trial orders are acceptable. We have a professional technical team and a service team. Supply aluminum material in different sizes and alloys. Stock material available.

Q5: What services can we provide?

A: Accepted Delivery Terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES;

Accepted Payment Currency: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY;

Accepted Payment Type: T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow;

Language Spoken: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian.