5 Key Factors That Affect the Price of Aluminium Circles

As a seasoned manufacturer in the aluminium industry, we have often heard one straightforward question from our clients: “What’s the aluminium circle price?” The simplicity of this question is just skin-deep. In fact, it speaks volumes about a complex interplay of global markets, manufacturing precision, and supplier reliability.

Knowing what determines the final price for aluminum circles gives you insight into making wiser purchase decisions. Let’s break it down into the five key factors that directly determine the amount you pay.

1. Raw Material Costs and Their Influence on Aluminium Circle Price

The most significant driver of cost is, unsurprisingly, the raw material itself. An aluminium circle starts its life as primary aluminium or a high-quality aluminium alloy. The price of this base metal is pegged to the London Metal Exchange, known as LME. When global demand, energy costs, or trade policies cause LME prices to fluctuate, the foundational cost of every aluminium circle shifts accordingly.

Besides, the type of alloy applied is very important. A general 1050 or 1060 alloy circle will differ in aluminum circle price from a 3003 or 5052 alloy that provides higher strength or corrosion resistance. As a manufacturer, we have to purchase high-purity aluminum, and any premium we pay for superior raw materials is inherently factored into the final product’s cost.

2. Manufacturing Process and Its Impact on Aluminium Circle Quality and Price

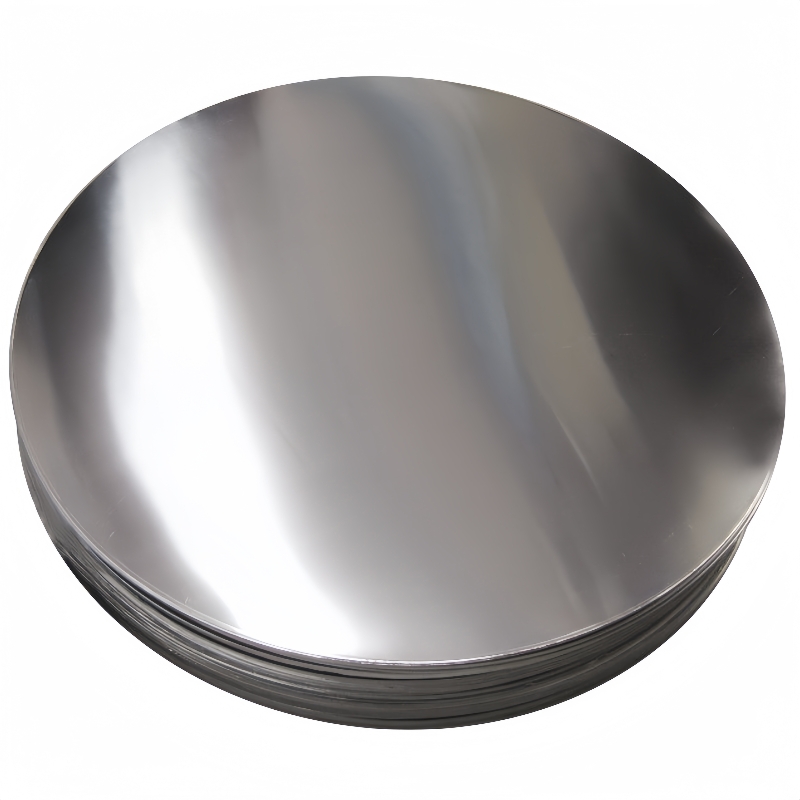

Not all aluminium circles are created equal, and what may start as an ingot develops through critical melting, casting, hot rolling, and cold rolling into that perfect flat, consistent circle. The precision and technology invested here directly impact both quality and price.

- Cold Rolling: This enhances the strength and surface finish of the aluminium circle. Tighter tolerances, together with a mirror-like finish, require more advanced rolling mills and control; therefore, increasing the manufacturing cost.

- Heat Treatment (Annealing): Annealing softens the aluminium, making it more formable for deep drawing applications. During annealing, precise temperature control provides consistent material properties-a true mark of a quality-conscious manufacturer. Skipping or poorly executing this step might lower the price, but results in a product prone to cracking during your manufacturing process.

Although it may appear that investing in such a technologically advanced process manufacturer involves higher costs, it saves you from material inconsistencies and production line rejects.

3. Specifications That Directly Affect Aluminium Circle Price

The cost of an aluminum circle is directly affected by specific requirements that you will set. Small changes in specifications can make a significant difference in the aluminum circle price, which may be more pronounced if you purchase it in bulk. The most important factors are:

- Diameter and Size Range

Larger diameters require wider aluminum coils and result in greater material waste during punching. The larger the size, the higher the cost per piece will be in general.

- Thickness of Material

Thickness is one of the most powerful cost drivers: the thicker the aluminum circle, the more raw material is consumed and, consequently, the higher the price. In turn, ultra-thin gauges often require more precise processing.

- Tolerance and Accuracy Requirements

Greater precision in thickness, diameter, or roundness requires better machinery and slower speeds. This increased accuracy raises both the time of processing and production costs.

- Temper and Mechanical Properties

Annealing and mechanical property control will be different for different tempers such as O, H12, H14, or H24. Circles designed for deep drawing or spinning may need a softer temper, which requires additional processing and impacts pricing.

- Surface Quality and Additional Treatments

Whether you require a mill-finish surface, polished finish, anodising, or other coatings will vastly affect the final price of the aluminium circle. More strict surface quality standards also require more detailed inspection and sorting to avoid scratches or stains.

Overall, defining the right specifications guarantees that you pay only for what is needed, without compromising performance in the final product.

4. Market Demand and Regional Supply Trends Affecting Aluminium Circle Price

In fact, the price of an aluminum circle does not exist in some kind of vacuum but is influenced by the global balance of supply and demand. If there is a surge in demand in key sectors such as cookware manufacturing, automobile production, or lighting, supply immediately gets tight, and prices start to go upwards. Likewise, an economic downturn in a major market would work in reverse.

Meanwhile, regional factors make big differences in prices. A manufacturer who has to contend with high local energy costs or strict environmental regulations intrinsically has very different production costs compared with a company whose region offers subsidized power. In any case, logistics are a critical, often overlooked, component. Global fluctuations in freight rates and fuel costs affect the final landed cost of your aluminium circles, so the “cheapest” supplier may not be the best value once the product hits your door.

5. Supplier Capability and Service Level of Aluminium Circle Manufacturer

While the temptation is there to focus on unit cost alone, it’s the manufacturer you choose that defines the value of your purchase. Capability and service level are critical elements of your aluminum circle manufacturer, which do have an impact on your total cost and operational efficiency.

A supplier’s technical expertise is your first layer of value: Can their technical team advise on the best alloy or temper to use for your particular deep-drawing process? Such advice can save you from very costly material failures and delays in production. In addition, consider operational reliability. A manufacturer with a solid level of productive capacity plus a demonstrated history of on-time delivery protects your own supply chain, ensuring your production lines will never stall while waiting for materials.

Finally, consider those ancillary services that turn a simple transaction into a partnership. Added value services such as precision custom cutting, protective packaging, and flexible logistics options can offer significant convenience and cost savings to your business. Therefore, often the most competitive price for an aluminium circle is a price that includes reliable service, professional support.

Final: How You Can Get the Best Price?

To ensure the most competitive price of aluminum circle without compromising the quality, the buyers can follow some practical strategies:

- Plan orders in advance to avoid seasonal price spikes.

- Instead, choose a supplier with stable raw material channels rather than chasing the lowest price.

- Clearly communicate specific requirements to avoid over-engineering and paying for features not needed.

- Build long-term cooperation—many customers receive better pricing because of consistent orders.

- Request samples and testing reports to verify actual performance before bulk purchase.

If you’re seeking a steady, competitively priced aluminium circle supplier offering the assurance of prompt delivery and the backing of robust manufacturing capability, don’t hesitate to get in touch with us. Our team can provide tailored quotations based on your exact specifications, along with samples and technical support to help you reduce procurement risks. Send us your requirements anytime-we’re ready to support your project.

Related Products