Applications of Aluminum Strips

Aluminum strip is an important basic material for the development of the national economy. it’s high aluminum content, it is also referred to as pure aluminum tape in the industry. This series of the aluminum belts has better plasticity, corrosion resistance, and electrical conductivity, thermal conductivity. Then where exactly can an Aluminum Strip be applied to? The following guide will let you know.

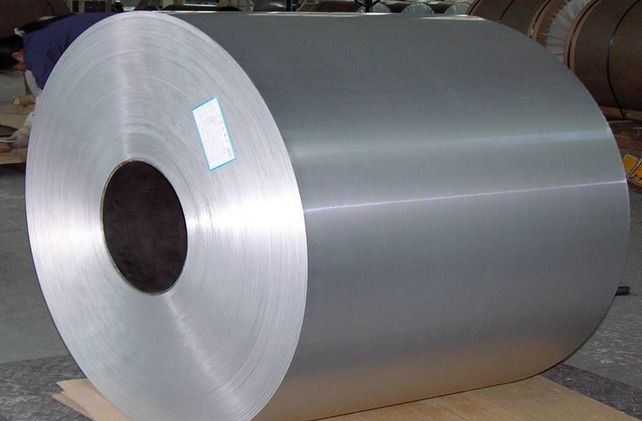

What is Aluminum Strip?

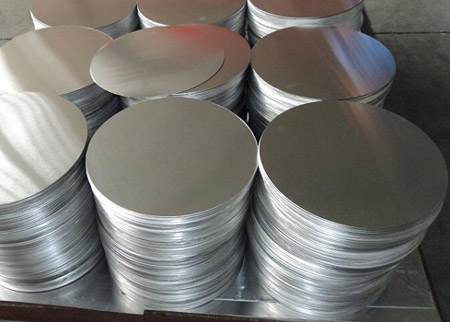

Generally, the raw material of aluminum strip is pure aluminum or aluminum coil cast and rolled with aluminum alloy, hot-rolled aluminum coil. The slitting machine slits longitudinally into aluminum strips of different widths. There are many classifications of aluminum strips. Common aluminum strip grades generally include 1050, 1060, 1070, 1100, 3003, 3004, etc., and there are generally two main states of aluminum strip: soft state and hard state, the soft state is general It is represented by the letter O, and the hard state is represented by the letter H. A number can be added after the two letters to indicate the hardness of the aluminum coil or the degree of annealing.

Why is Aluminum Getting More Popular in Industry?

In industry, aluminum is often of relatively high quality, and its surface has been treated with anti-oxidation, has anti-corrosion and anti-rust properties, and has a variety of colors. Moreover, aluminum is a recognized all-environmental protection material, which can eliminate the source of industrial pollution. After strict processing and film, it does not contain elements that are harmful to the body. In conclusion, industrial aluminum products have a fine texture, simple lines, and generous, long service life, durability, and simple daily maintenance. They are good industrial products in people’s minds. Especially aluminum trips are being widely used in many fields of our life which you might haven’t noticed yet, then you would be curious about what field can it be applied to? In the following passage, I would show you the types and applications of an aluminum strip.

Types and Application of an Aluminum Strip1060 Aluminum Strip

This kind of aluminum strip has relatively high requirements for the corrosion resistance and formability of the working environment, on the contrary, the requirements for strength are not particularly high, so the 1060 aluminum strip is mostly used in the chemical equipment industry.

- 1100 aluminum strip

This kind of aluminum strip does not have any rigid requirements for high-strength parts, but it will require very good corrosion resistance and formability in the processing environment. A ship will be used for equipment and storage containers in the food industry. In the processing, processing of chemical products, welding parts, heat exchangers, nameplates, reflective appliances, and processing of printing plates, the application fields are very wide.

- 3003 aluminum strip

Generally, cold-worked bars, cold-worked wires, forgings, foils and heat sink materials in this type of aluminum strip are mainly used for high corrosion resistance, good formability and very good weldability. Among the components, they can also play a very good role in industries such as pressure tanks, heat exchangers, chemical equipment, oil ducts, kitchen equipment, aircraft fuel tanks, and reflectors.

- 3004 aluminum strip

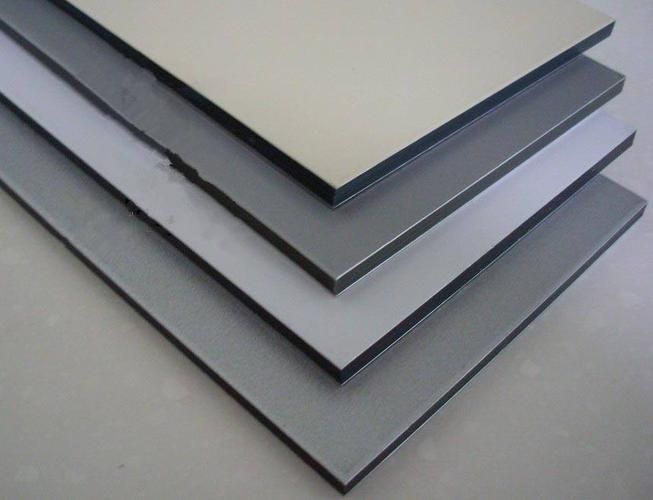

This type of aluminum tape is mostly used in the production and storage of chemical products, in the production of lighting components, in the production of cable pipes and sewers, and in the industries of building baffles and building processing parts.

If you are looking for a reliable Aluminum Strip Manufacturer, I recommend you Lanren Aluminum, it has the whole line to produce aluminium coil and circles and aluminium cookware.