Cookware Material Comparison: Heat Conductivity, Durability, and Cost

Choosing the right cookware material is a critical decision for any home cook or professional chef. The performance of your cookware directly impacts cooking efficiency, food quality, and long-term usability. This article compares common cookware materials, focusing on their heat conductivity, durability, and cost, with a special emphasis on aluminum for its unique advantages.

Common Types of Cookware Materials

Cookware materials vary significantly in their properties, influencing how they perform in the kitchen. The most common materials include stainless steel, cast iron, copper, non-stick coatings (often applied over aluminum or stainless steel), and aluminum itself. Each has carved out a niche due to its inherent strengths and, sometimes, its limitations.

Let’s delve into the typical uses and general characteristics of these prominent cookware materials:

| Material | Characteristics | Applications | Example |

| Stainless Steel | Robust, rust-resistant, non-reactive. | Everyday cooking: sauces, sautéing, boiling. | A 3-ply stainless steel saucepan for bechamel sauce. |

| Poor heat conductor; often clad with aluminum or copper for even heating. | Suitable for acidic ingredients like tomatoes and wine. | ||

| Cast Iron | Exceptional heat retention, durable, requires seasoning to prevent rust. | Searing meats, frying, baking (e.g., cornbread), slow-cooked stews, and deep frying. | Searing steak in a preheated cast iron skillet. |

| Reactive to acidic foods unless well-seasoned. | |||

| Copper | Superior heat conductivity, highly responsive to temperature changes. | Precision cooking: delicate sauces, candies, reductions. | Making hollandaise sauce in a copper saucepan. |

| Often lined with tin or stainless steel to prevent reactivity. | |||

| Non-stick Coated | Excellent food release, ideal for low-fat cooking. | Cooking delicate foods like eggs, pancakes, crepes, and fish. | Frying an egg in a non-stick pan ensures easy release. |

| Base metal is usually aluminum or stainless steel. | |||

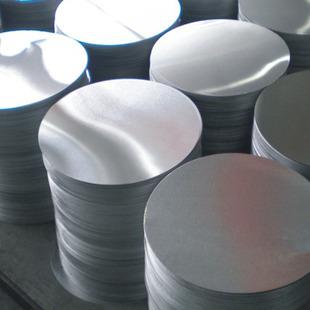

| Aluminum | Lightweight, inexpensive, excellent heat conductor. | Everyday cookware: frying pans, bakeware, stockpots. | A large aluminum stockpot for boiling pasta or soup. |

| Often anodized or coated to reduce reactivity with acidic foods. | Anodized aluminum is great for frying and sautéing due to its non-stick properties. |

Each material brings its unique advantages to the kitchen, catering to different cooking needs and preferences. Understanding these foundational types is essential before diving into a detailed comparison of their core performance characteristics.

Key Cookware Material Characteristics for Comparison

When evaluating cookware, three primary characteristics stand out: heat conductivity, durability, and cost. These properties dictate not only how a pan performs but also its longevity and overall value. Let’s explore how different materials stack up in these critical areas, with a particular focus on the compelling advantages of aluminum.

Heat Conductivity

Heat conductivity refers to a material’s ability to transfer thermal energy. In cookware, high conductivity means heat spreads quickly and evenly across the pan’s surface, preventing hot spots that can scorch food and ensuring consistent cooking.

Heat Conductivity Performance Across Materials

| Material | Thermal Conductivity (Approx. W/(m·K)) | Heat Transfer Characteristics |

| Copper | 398 | Exceptional. Heats almost instantly and responds immediately to temperature changes. Offers unparalleled control, ideal for precise culinary tasks. |

| Aluminum | 205-225 | Excellent. Heats quickly and distributes heat uniformly. Highly efficient at preventing hot spots, leading to even cooking and faster results. Strong second only to copper. |

| Cast Iron | 52 | Low conductivity, but excellent heat retention. Heats slowly but retains heat exceptionally well once hot. Ideal for maintaining consistent high temperatures for searing and deep frying. |

| Stainless Steel | 16 | Poor conductor on its own. Prone to hot spots. High-quality stainless steel cookware is typically “clad” with layers of more conductive metals (aluminum or copper) in its core to significantly improve heat distribution. |

Aluminum’s high heat conductivity is a significant advantage. Its ability to heat up quickly and distribute heat evenly means less energy is wasted, and food cooks uniformly. For example, when sautéing vegetables, an aluminum pan will ensure all pieces cook simultaneously without some burning while others remain raw. This efficiency also translates to faster cooking times and more predictable results. Compared to copper, aluminum offers comparable heat performance at a fraction of the cost, making it an accessible choice for superior heat transfer.

Durability

Durability in cookware refers to its resistance to warping, scratching, denting, and corrosion, directly impacting its lifespan and long-term value.

Durability Performance Across Materials

| Material | Durability Characteristics |

| Cast Iron | Exceptionally durable. Virtually indestructible under normal use; can withstand very high temperatures and impacts without warping. Prone to rust if not properly seasoned and maintained. |

| Stainless Steel | Highly durable. Resistant to corrosion, rust, and scratching. Maintains appearance well over time and handles aggressive scrubbing. High-quality clad stainless steel is very robust. |

| Aluminum | Generally durable. Bare aluminum can be softer and prone to scratching/denting. However, anodized aluminum significantly enhances durability, creating a hard, non-porous surface that is much more resistant to scratches and corrosion (sometimes harder than stainless steel). Non-stick coatings on aluminum are the least durable. |

| Copper | Relatively soft. Prone to denting and scratching. Internal lining (tin or stainless steel) is susceptible to wear, especially tin due to its lower melting point. |

When considering durability, especially with anodized aluminum, its resistance to corrosion and wear becomes quite impressive. While lighter than cast iron or stainless steel, a well-made anodized aluminum pan can withstand significant use. Its relative lightness also reduces the risk of accidental drops and damage to other kitchen surfaces. For example, professional kitchens often use heavy-gauge aluminum stockpots because they are durable enough for constant, high-volume use while remaining manageable to lift.

Cost

Cost is a practical consideration for most consumers, encompassing both the initial purchase price and potential long-term expenses like replacement or energy consumption.

Cost Performance Across Materials

| Material | General Cost Range | Referred Price Range (Individual Piece/Set) |

| Copper | Highest. By far the most expensive, due to high raw material cost and specialized manufacturing. A single saucepan can cost several hundred dollars. | Single Piece: $100 – $500+ (e.g., skillets, saucepans) Sets: $800 – $3,000+ |

| Stainless Steel | Varies widely. Entry-level is inexpensive. High-quality, fully clad sets can be quite costly, sometimes rivaling or exceeding the price of some copper pieces. | Single Piece: $20 – $200+ (e.g., skillets, saucepans) Sets: $100 – $1,000+ (depending on cladding and brand, high-end sets can be $500-$900+) |

| Cast Iron | Most affordable. Generally the cheapest option, especially for traditional bare cast iron. Offers very low long-term cost due to its exceptional longevity. | Single Piece (Bare): $15 – $70 (e.g., skillets, Dutch ovens) Single Piece (Enameled): $50 – $300+ (e.g., Dutch ovens, casseroles) Sets: $50 – $200+ |

| Non-stick | Moderately priced. Prices vary based on base material and coating quality. However, their shorter lifespan often leads to higher replacement costs over time compared to more durable materials. | Single Piece: $20 – $150 (e.g., frying pans, sauté pans) Sets: $50 – $300 (can go higher for premium brands and larger sets) |

| Aluminum | Exceptionally cost-effective. Bare aluminum is one of the cheapest. Anodized and non-stick aluminum pans remain significantly more affordable than comparable copper or high-end clad stainless steel options, offering an excellent cost-to-performance ratio. | Single Piece (Bare/Basic): $10 – $50 Single Piece (Anodized/Non-stick): $20 – $100 Sets: $40 – $250 (can be higher for larger, high-quality anodized sets) |

Aluminum’s affordability makes high-performance cookware accessible to a wider audience. For its excellent heat conductivity and reasonable durability (especially anodized), the cost-to-performance ratio of aluminum is outstanding. This allows home cooks to acquire a comprehensive set of quality cookware without a prohibitive investment. A high-quality aluminum sauté pan might cost $50-$100, offering heat distribution comparable to a $300 copper pan. This makes aluminum an intelligent economic choice for building a functional kitchen.

Other Important Considerations

Beyond the core three, other factors can influence cookware choice:

- Reactivity with Food: Bare aluminum and cast iron can react with acidic foods, potentially imparting a metallic taste or causing discoloration. Stainless steel, anodized aluminum, and lined copper are non-reactive.

- Weight and Handling: Aluminum is significantly lighter than cast iron or even stainless steel, making it easier to lift, move, and clean, particularly for larger pots and pans.

- Maintenance and Cleaning: Non-stick and anodized aluminum are generally easy to clean. Cast iron requires specific seasoning and drying to prevent rust. Copper needs polishing to maintain its aesthetic appeal.

- Oven Safety: Most metal cookware is oven-safe, but handles (especially plastic or silicone) and non-stick coatings may have temperature limitations.

- Induction Compatibility: Bare aluminum and copper are not inherently magnetic and thus not compatible with induction cooktops unless they have an added ferromagnetic base layer. Cast iron and stainless steel are generally induction compatible.

Considering these characteristics comprehensively reveals that each material offers a unique balance of properties. However, aluminum consistently presents a compelling case, particularly when its excellent heat conductivity and cost-effectiveness are weighed against its practical durability in anodized forms.

Choosing the “Best” Cookware Material

The quest for the “best” cookware material often leads to a nuanced answer: there isn’t a single universal champion. Instead, the ideal choice hinges on a combination of individual cooking style, budget constraints, and specific culinary aspirations. Attempting to find one material that excels in every scenario is unrealistic; instead, a pragmatic approach involves building a versatile “cookware wardrobe.”

For instance, while cast iron is unparalleled for achieving a perfect sear on a steak due to its heat retention, it would be cumbersome and slow for boiling a large pot of pasta water. Similarly, while copper offers exquisite control for delicate sauces, its high cost and specific maintenance requirements make it impractical for everyday tasks for many home cooks. Stainless steel, lauded for its durability and non-reactivity, may fall short in heat distribution compared to aluminum or copper unless it’s a high-quality clad version.

Therefore, the “best” cookware collection often comprises a strategic mix of materials. A high-quality clad stainless steel set might form the backbone for general cooking, complemented by a cast iron skillet for searing and baking, and a non-stick pan for eggs. Within this mix, aluminum frequently emerges as an indispensable component. Its balance of rapid, even heating, lightweight nature, and affordability makes it an excellent choice for a wide array of cooking applications, from everyday sautéing to simmering large quantities of soup. For example, a home cook might use a cast iron pan for frying chicken, a clad stainless steel pot for making soup, and an aluminum non-stick pan for breakfast items. This diversification ensures that each cooking task benefits from the most appropriate material properties.

Ultimately, understanding the strengths and weaknesses of each material empowers you to select pieces that genuinely enhance your cooking experience. It’s about matching the tool to the task, recognizing that different materials excel in different environments.

Related Products