Advantages of Using Aluminium Discs in the Cookware Industry

Nowadays, more and more cookware brands choose to use aluminium as the raw material for manufacturing cookware, because it can play the biggest purpose of cookware. We should all know that to produce a pot, we must first start with the production of discs. So why use aluminium discs, how are aluminium discs made, and what are the characteristics or advantages of cooking utensils made of aluminium discs? This article will provide detailed answers to the above questions.

Why is aluminium so popular in cookware?

Because it is lightweight, aluminum is ideally suited for large parts like cooking pans and baking dishes rodo pans and huge water pans, specifically when coated with anodized or non-stick.

Aluminium is a fantastic heat conductor, as well as being less expensive than stainless steel cookware and pans. It permits the production of extremely manageable items. It is also completely recyclable, hygienic and impact and resistant to corrosion. Aluminium evenly distributes heat over every surface in the pot, thereby increasing the cooking process of various kinds of food items.

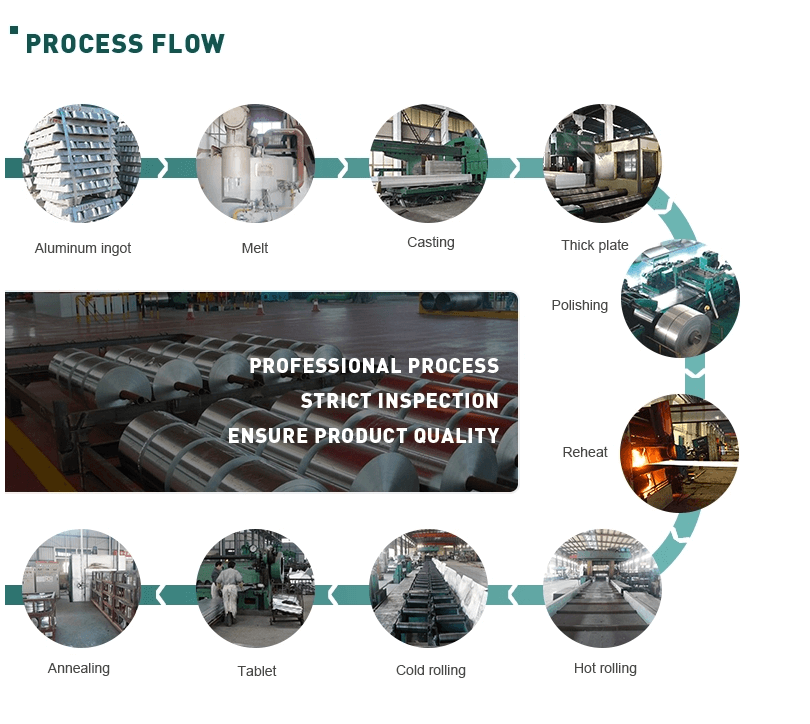

How are aluminium discs made?

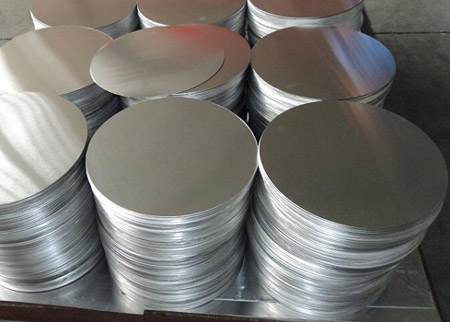

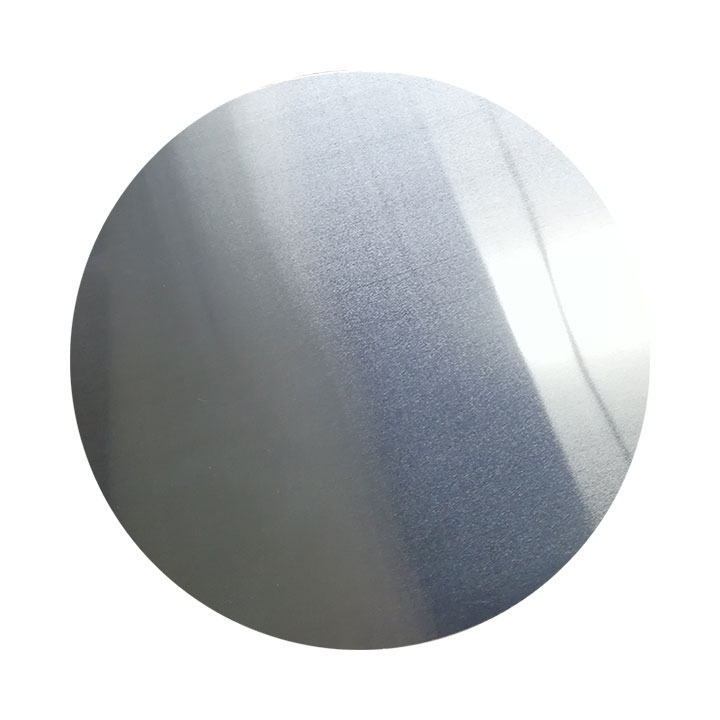

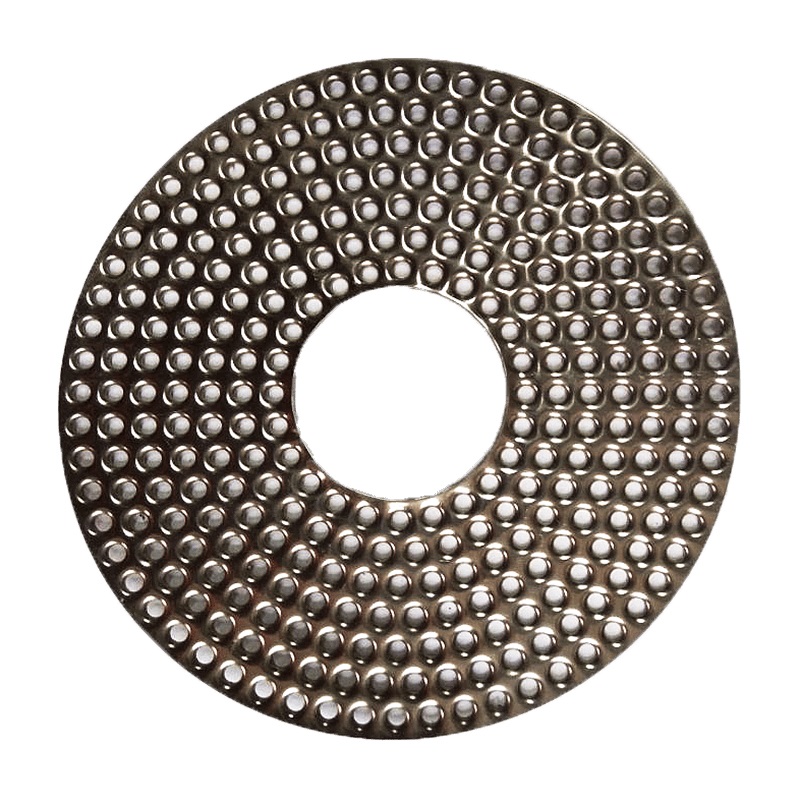

In short, an aluminium disc is a disc made of this metal. According to your needs, you can choose different sizes. We mentioned earlier that the premise of making a pot is to make a disc. So what is the main process of making an aluminum circle? Here is the answer:

After the hot rolling process, the cold rolling stage will reduce the aluminum to the thickness required by customers. Then, the coil is passed through a press, and a disc of the required diameter is cut out on the press. Finally, put the discs into an oven for annealing treatment: this can give the metal proper mechanical properties and make deformation (deep drawing) feasible in order to obtain the desired pot or pan.

What are the characteristics of a cooker made of aluminium circle?

What are the characteristics of a cooker made of aluminium discs?

The thermal conductivity of pure aluminum is second only to copper. It is cheap, and after strengthening (usually by adding magnesium, copper or other metals), you can make lightweight and responsive cookware by yourself.

In order to solve the well-known shortcoming that natural aluminium reacts with certain acidic foods, the best way is: either lined with a non-stick coating, or covered with stainless steel, or anodized (this process will obviously harden the surface, And make it have a very dark gray). In fact, more and more manufacturers are processing anodized aluminium discs. These anodized aluminum discs are also non-stick or non-corrosive. It is attractive enough, more durable and easier to clean. Nowadays, various aluminum processing technologies are becoming more and more mature, and there are a variety of high-performance, non-reactive aluminium cookware to choose from.

Of course, before deciding to make an anodized aluminium pan, you need to choose anodized aluminum discs. This kind of aluminium disc can make non-stick and stainless cookware. Secondly, the aluminium disc has a higher density and can be used at the bottom of the cookware to enhance the sealing of the cookware. The cookware with a sealed base will:

- Enhanced cooking performance

- Fewer hot spots, especially when cooking pasta and fine sauces

- Has better and more uniform heat distribution

- Improved thermal insulation

In order to ensure that you buy the best aluminum discs, you must cooperate with leading aluminium suppliers. For many years, LANREN has been providing customers with excellent aluminium materials and aluminum products, and is in a leading position in all products sold. In addition to excellent quality, we also save you money because your order is shipped directly to your factory from an overseas company. To get more information about our company and services, please visit our website or call us immediately.