Some Common Knowledge of Aluminium Chequered Plate

In life, our common aluminium chequered plates are mostly used for pedals under our feet, such as stairs, steps, garages and other places. In addition, what other areas can aluminium chequered plates be used in? How is aluminium chequered plate made from the plain aluminium plate? What should the factory pay attention to when choosing an aluminum plate supplier? This article will answer these questions one by one.

How is an aluminium checkered plate made?

Metal aluminium generally comes from bauxite. After mining the bauxite, it is washed away from the clay adhered to it, then ground and ready to be used to extract alumina. The next step in this process is the production of aluminium metal. This is done with the help of carbon and electricity. In a process called electrolysis, negative and positive cathodes made of carbon are used, and then alumina is converted into a liquid state and CO2 is produced. Then, this liquid aluminium is poured into different molds to produce ingots or slabs, which are then used to make aluminium plates and sheets.

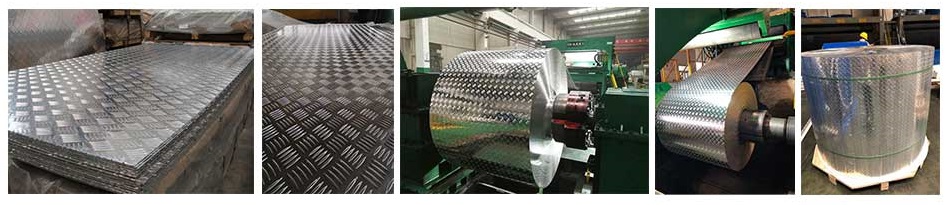

After the aluminium plate is made, there are two main ways to manufacture the aluminium chequered plate, one is rolling, and the other is stamping:

- Rolling:

Most metal plates are made through a rolling process, during which pairs of heavy rollers gradually compress very hot metal blocks to produce the required thickness and cross-section. The aluminium diamond plate can be created at the end of the rolling process while the metal is still hot, or in a separate process after the metal plate has cooled. Either way, one of the rollers is covered in a raised diamond pattern. By using only one patterned roller, the resulting aluminium diamond plate will remain smooth and flat on the back, making installation easier.

- Stamping:

The sheet metal press uses a metal mold on a room temperature metal plate to produce a raised diamond pattern. After the compression mould is pressed to imprint the small sheet, the automatic machine moves the sheet along the roller bed, and then the module imprints the next part until the entire sheet is imprinted.

Some common uses of the aluminium checkered plate

In life, we can often see some applications of aluminium panels, such as car body and panelling, building wall panels and traffic signs. As a kind of aluminium plate, where are the main applications of the aluminium chequered plate?

Because of its special appearance and relatively regular pattern, the aluminium chequered plate has the purpose of decoration and anti-skid. Specific applications are in the following areas:

- Wall panels: Different from other wall decoration materials, aluminium chequered plates have a longer service life and high economic benefits. You can customize the chequered aluminum plate according to your needs, and it is easy to install by yourself. If you don’t want to use a complete wall panel, you can also make a simple modification to the interior by using aluminum rhombus panels as smaller tiles or as corner guards. It also looks very classic and very attractive. Doing so can improve the monotony of the wall and make the wall look more unique.

- Commemorative signs for outdoor display: Because metal aluminium has strong corrosion resistance and low maintenance costs, it is often used for outdoor billboards or monuments.

- Public places: Due to the high quality of aluminium, the aluminium chequered plate is easy to clean and has high resistance, so it is often used in public places, such as parking lots, garages, elevators, and disabled access.

- Places that need to improve the anti-slip force: Because the aluminium chequered plate has a raised pattern on the surface, it can have a good anti-slip effect and can be applied to steps, stairs, floors, loading and unloading yards and other places to provide traction.

- Decoration: The patterned aluminum plate can be used for decoration because of its special texture, and the plasticity of aluminum is strong, so it can be cut or processed into artwork or signs.

For different purposes, there are also types of aluminium chequered plates. LANREN can provide you with the following aluminium chequered plate styles, namely:

- Aluminium tread plate

- Embossed firetruck quality (FTQ) tread plate

- 5-bar aluminium chequered plate

- Polished tread pattern aluminum plate

Which kind of aluminium plate is required depends on your specific needs.

What should you pay attention to when choosing an aluminum chequered plate supplier?

In various industries, choosing a supplier is a matter of great care. Choosing an aluminium chequered plate supplier is no exception. The following are some suggestions when choosing a supplier for this industry:

- Differences – Although the required products are the same, the products provided by different suppliers may be different. When choosing a patterned aluminium plate supplier, the first thing you should look at is the professionalism of the supplier and the credibility of the product quality.

- Production process – The aluminum plate supplier should provide samples of the aluminum plate produced by the supplier, and ensure that the supplier should use advanced equipment when producing the aluminum plate, and the finished product can meet the high standards of the industry.

- Price – People are accustomed to buying high-quality products as long as they use high prices, but the fact is that the same product can be obtained at a cost-effective price if the middleman or other costs are eliminated.

- Delivery cycle – what the factory production line needs most is the timeliness of raw material supply. When selecting an aluminum sheet supplier, the stability of the supplier’s delivery cycle should be ensured as much as possible, which is related to the integrity of an enterprise.

As a global supplier of aluminum plates, LANREN guarantees that its products are of superior quality and competitive prices. We have a wealth of experience, and our aluminium products are sold all over the world, and we have received unanimous praise from our customers. To learn more about our aluminum plates and their processes, we invite you to browse our website or call to talk directly with a representative.