What’s the Best Aluminium Alloy for Machining

Aluminum is the best choice for machining because of its lightweight, corrosion resistance, and outstanding working capabilities. However, it is not the case that all alloys of aluminum are identical. Some can cut as butter, while others require slow speeds and special tools.

What alloy of aluminum is the best to use for machine work? This article will look at the elements that make an alloy of aluminum appropriate for machining. We also review the most popular aluminum alloys that are used in CNC as well as traditional machining, and offer some tips for choosing the right alloy for your task.

What Makes an Aluminium Alloy Good for Machining?

Machinability determines how efficiently aluminum can be cut, drilled, or milled without excessive tool wear or poor surface finish. Key factors include:

- Alloy Composition: Elements such as silicon (e.g., 4047) enhance chip breaking while copper (e.g., 2024) increases strength but also reduces the tool’s lifespan.

- Hardness vs. Ductility: Softer alloys (e.g., 1100) cut easily but may gum up tools, while harder alloys (e.g., 7075) require slower speeds.

- Thermal Conductivity: Aluminum disperses heat rapidly; however, improper cooling can cause a buildup edges of tools.

- Chip Formation: The ideal alloys create small, brittle chips (e.g., 6061) instead of long strings (e.g., 5052, for instance).

The Aluminum Association’s machinability rating (1–5) ranks alloys—6061 scores ~4.5, while 7075 ranks ~2.5 due to its abrasive nature. For the best results, match the alloy to your tooling, coolant use, and finish requirements.

Top Aluminium Alloys for Machining

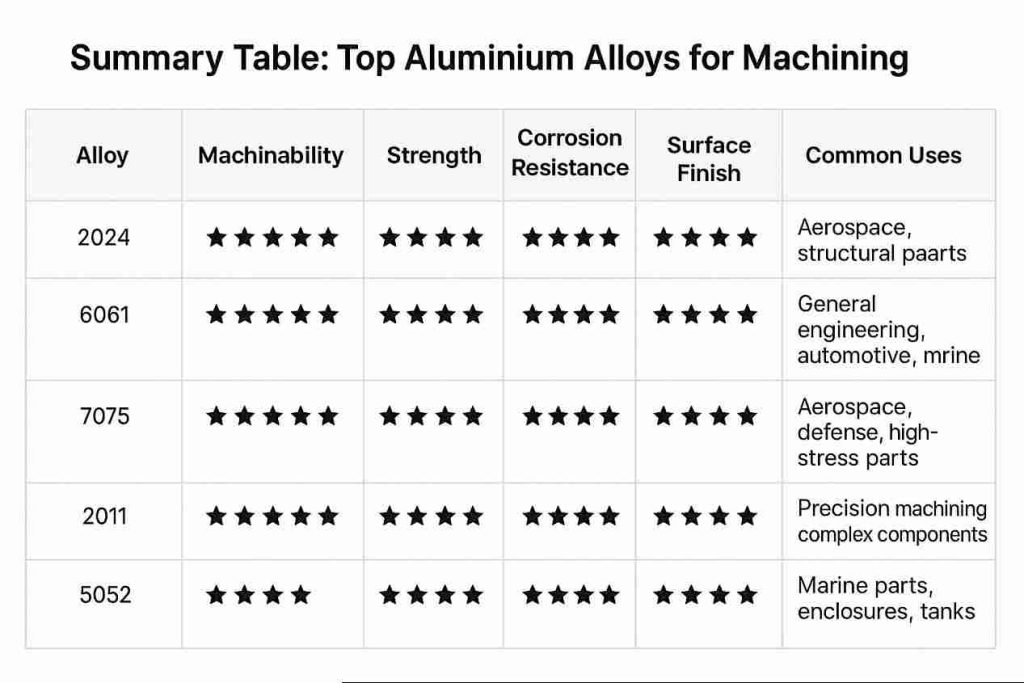

When selecting an aluminum alloy for machining, engineers and manufacturers must consider machinability, strength, corrosion resistance, and cost. Below, we break down the top three alloys—2024, 6061, and 7075—along with alternative options for specialized applications.

Aluminum 2024

Aluminum 2024 is best for high-strength, precision aerospace components.

2024 is a copper-based alloy (4.4% Cu) known for its excellent strength-to-weight ratio and fatigue resistance. It’s widely used in aircraft structures, gears, and hydraulic systems where load-bearing performance is critical.

Machining Characteristics:

- Moderate machinability (rated ~3.5/5) – Requires sharp carbide tools and proper chip evacuation.

- Tendency to work-harden – Interrupted cuts (e.g., drilling holes) may cause tool deflection if feeds are too slow.

- Poor corrosion resistance – Must be anodized or coated if exposed to harsh environments.

Use 2024 when you need high strength and fatigue resistance, but be prepared for slower machining speeds compared to 6061. A soluble oil coolant helps prevent built-up edge.

Aluminum 6061

6061 is the most popular aluminum alloy for machining, having an almost perfect combination of workability, strength, and corrosion resistance. Its magnesium-silicon content (1.0% Mg, 0.6% Si) makes it highly suitable for automotive frames, marine hardware, and CNC prototypes.

Machining Properties:

- Good machinability (rated ~4.5/5) – Forms short, brittle chips that reduce re-cutting and tool wear.

- Stable cutting performance – Less prone to built-up edge than 2024 or 7075.

- Good surface finish – Easily polished or anodized post-machining.

The trade-offs are:

Lower tensile strength (~310 MPa) compared to 2024/7075. Not suited for high-temperature uses (loses strength above 150°C).

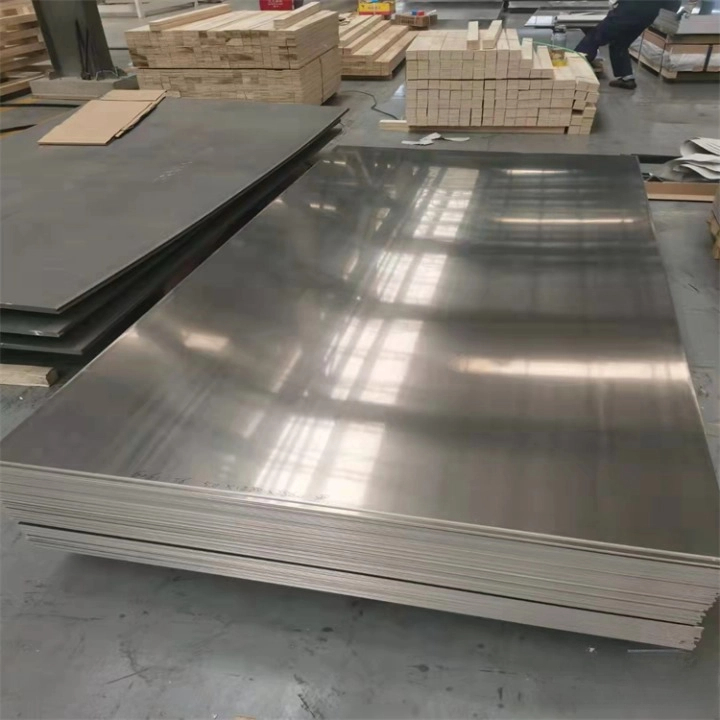

6061 is the standard option for the majority of machining projects. It’s beginner-friendly, affordable, and easy to find in bars, sheets, and extrusions.

Aluminum 7075

If maximum strength is a primary design requirement, 7075 is likely on the shortlist. This alloy is significantly stronger than 6061 and is often used in aerospace, motorsport, and military applications where high mechanical performance is critical. Though slightly more challenging to machine than 6061, it still offers good results with the right tools and techniques, particularly in the T6 and T73 conditions.

One drawback of 7075 is its lower natural corrosion resistance, which again may require post-processing treatments. But in terms of machining, it holds tight tolerances well and can deliver clean finishes with proper feeds and speeds.

Other Alloys

- 2011: So-called “free-machining” aluminum, this alloy excels at high-speed turning and precision parts where a fine finish on the surface is required. It’s a decent aluminum to machine but it has poor corrosion resistance.

- 5052: Very corrosion-resistant and highly suitable for marine applications, but more difficult to machine smoothly than 6061.

- 6262: It is an alloy that blends good strength with enhanced machinability, due to the introduction of lead and bismuth. It finds extensive use where an even trade-off between performance and ease of machining is demanded in an application.

Each of these alloys offers its own set of advantages, and the best choice depends heavily on your application’s performance, surface, and environmental needs.

How to Choose the Right Aluminium Alloy for Your Project

Selecting the appropriate alloy of aluminium will depend on the requirements of your project. Here are the most important aspects to take into consideration:

- Mechanical Requirements: Determine the strength, hardness, and fatigue resistance required. For instance, parts with high stress might require 7075, whereas general-use parts could work with 6061.

- Environment: The part will be exposed to saltwater, moisture, or other chemicals? Metals such as 5052 or 6061 provide better resistance to corrosion in those environments.

- Machinability Needs: If your project involves complex or high-speed machining, choose an alloy known for good machinability, such as 2011 or 6061-T6.

- Surface Finish and Appearance: Certain alloys provide more polished, smoother surfaces than other alloys. If aesthetics or treatments for surfaces (like Anodizing) matter, think about either 6061 or 2024.

- Formability and Weldability: If bending or welding is part of the process, ensure the alloy you choose to use is compatible. For instance, 5052 is extremely formable and weldable. 7075 is not suitable for welding.

By carefully balancing these factors, you can choose the aluminium alloy that delivers the best performance, ease of machining, and cost-effectiveness for your specific project.

In A Word

For most projects, 6061 offers the best balance of machinability, strength, and cost. Reserve 7075 for extreme strength and 2024 for aerospace needs.

Need machinable aluminum stock? We supply 6061, 7075, and 2024 in circles, sheets, bars, and custom cuts etc. Contact us to learn more information today!

Related Products