How to Choose a Top Aluminum Circle Supplier?

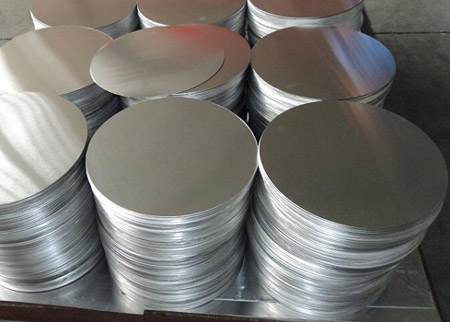

Global production volume of aluminum circles has increased significantly with their extensive applications in many industries. As a raw material, the aluminum circle is the initial blank for numerous finished products. It has applications from everyday commodities like pots, pans, and kitchen utensils to specialized components for industrial and commercial use.

Aluminum Circles and Aluminum Blanks

Many people struggle with the difference between aluminum circles and aluminum blanks. But knowing this difference will be important for choosing and buying the right materials. Aluminum blanks are pieces of aluminum that are big and flat and later get cut, stamped, or machined into specific detailed parts. Aluminum circles, however, are discs that have already been blanked and cast into a circle. Aluminum circles come ready for deep drawing, spinning or light finishing, so they’re the best starting material for products that have a round base.

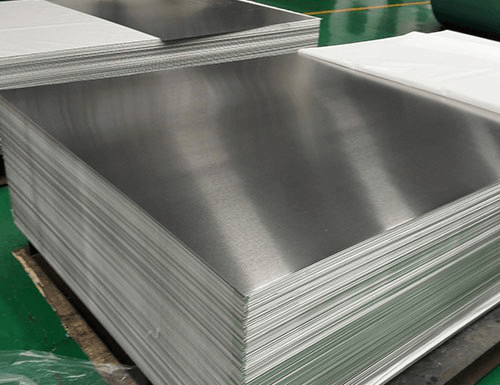

Choosing the Right Specs for Your Product

Getting the right dimensional and alloy specifications for your product is the key for it to be successful. A product’s functionality and structural requirements determine the diameter and thickness of the aluminum circles, they are not arbitrary.

- Large Diameter Applications: Variants such as satellite dishes or really big industrial lids, structurally need thicker and larger circles.

- Small Diameter Applications: Kitchen cookware, like frying pans and lids, require circles in the smaller diameter range and with specified thicknesses for optimal heat distribution and ease of forming.

- Alloy Considerations: The size is one of the many specifications of the aluminum alloy grades like 1050, 1060, 3003, or others with respect to the attributes of desired strength, thermal conductivity, or formability.

Strategic Sourcing: A Key Factor in Your Success

Just as in every step of the sourcing process, selecting a supplier must become a strategy of competitive differentiation since it directly affects product quality as well as manufacturing efficiency. The advantages of collaborating with qualified top aluminum circle suppliers include:

- Expertise. Top suppliers offer recommendations on the best alloys, tempers, and sizes for the specific application in a way that maximizes performance and minimizes cost.

- Quality and Uniformity. Uniformity of quality and neatness of finishing, and precision of mechanical properties impact the consistency of production. Ending products with varying quality becomes a customer complaint.

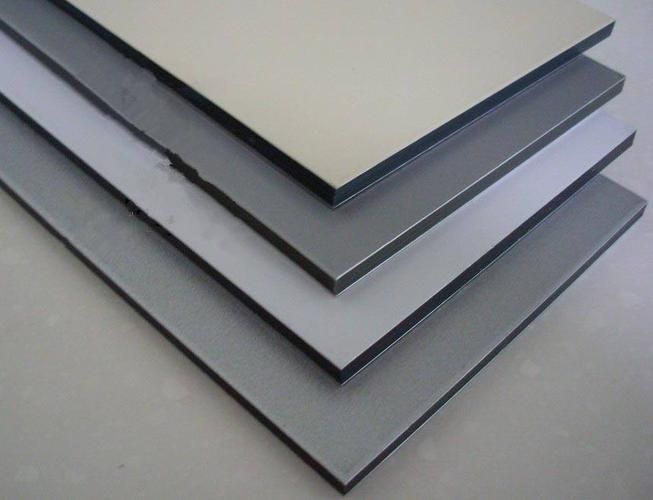

- Diverse Products. Beyond standard mill-finish circles, sophisticated suppliers also provide specialized versions, including pre-painted aluminum circles designed for high-strength, non-stick cookware or other demanding applications, which add flexibility and value.

Production Process&Precision

Several conditions must be in place for the production of high-grade aluminum circles, which can also be used to judge potential suppliers of aluminum disks.

1. Technical Competence of Personnel

Having qualified personnel who understand the basic steps in the production process is a must. Having proficient technicians in the production process, the end product will more likely be free of complications associated with poor production. In addition, the production of aluminum circles of high value is also the result of production method mastery, coupled with the production range of offerings. Increased production value, coupled with more proficient production methods, results in high-value aluminum circles. Thus, intensive production methods and extensive production methods range from the pillars of unrivaled production value.

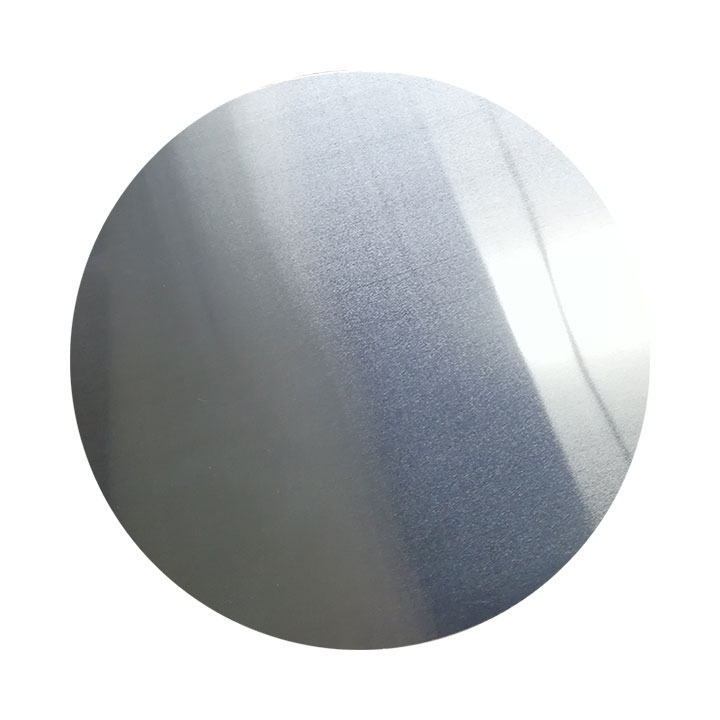

2. Precision as a Key Quality Indicator

The aluminum non-stick circle, or aluminum disc/disk, is a highly valued industrial product. Its functionality must meet rigorous requirements, especially in the high-precision fields of aviation and electronics. In these fields, slight deviations will result in outstanding differences in function. Due to this, an aluminum circle’s quality is generally gauged by its dimensional precision and functional precision. More accurate products are naturally superior. Such accuracy directly depends on the producer’s production capability and technical equipment. Only with superior equipment and developed production technology can extremely precise aluminum circles be manufactured stably.

Aluminium Supplier

In Lanren Aluminum Company, we have a full range of aluminum circles available for sale. Lanren was established in 2008, with more than ten years of experience in aluminum circle production. We have established long-term business ships with the United States, Canada, Australia, Mexico, Spain, France, India, and South Africa.

Our products cover aluminum coil, aluminum plate, aluminum coil, aluminum composite, cookware set, aluminum frying pan, aluminum baking pan, aluminum baking tray, cake mold, and aluminum ribbon. We can also provide different sizes of aluminum pull-down circles, aluminum induction circles, and aluminum color coating discs. To learn about our aluminum circle and other available products, please visit our website. If you need, you can contact us by phone, communicate with team experts.