Several Applications of Aluminum Foil

Aluminum foil with excellent performance is gradually replacing the application of copper foil in various fields, promoting the substitution of copper with aluminum strip, will be able to better use of aluminum resources copper resources. And aluminum foil basically replaced copper foil, and achieved the same performance.

Today, by reading this article, you can learn about several important applications of aluminum foil.

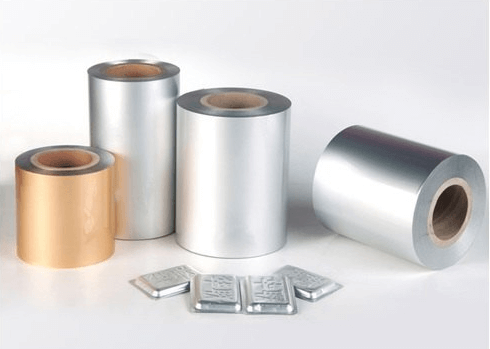

Pharmaceutical Aluminium Foil

There are several types of pharmaceutical aluminium foil, such as pharmaceutical aluminium foil, pharmaceutical PTP aluminum foil, pharmaceutical packaging with PTP aluminum foil, PTP aluminum foil. The material of pharmaceutical aluminium foil requires high precision printing, rich color and clear pattern. And it is required that the plain foil can be printed online on the automatic drug blister packing machine. In addition, it also requires good moisture permeability, moisture resistance, oxygen resistance, sealing with molding materials, can avoid light, incense. Using aluminum foil as the base material, easy to open or break, convenient for consumers to take.

Air Conditioning Aluminum Foil

Air conditioner foil is a special-purpose product used in the manufacturing of fins for air conditioner heat exchangers. It was initially plain foil, but plain foil did not possess much surface performance in its original state. Anticorrosive inorganic paint and hydrophilic organic paint were thus applied before forming, resulting in a hydrophilic foil. Hydrophilic foil presently accounts for approximately 50% of air conditioning foil usage today and will continue to grow further.

Apart from hydrophilic types, hydrophobic foil has been developed to provide a water-repellent coating that prevents the adhesion of condensation. However, because of the fact that technologies to enhance surface defrosting for hydrophobic foil are in the process of development, their actual production remains very limited.

Physical Requirements

The average thickness of air conditioning foil is 0.1 mm to 0.15 mm. With improvements in technology, thinner foils are the tendency; for example, the best Japanese brands now offer foils as thin as 0.09 mm. When very thin thicknesses are used, the aluminum must be highly formable, and for this, it requires a uniform structure, low metallurgical defects, low anisotropy, high strength, good ductility, thickness uniformity, and flatness.

Despite these tough conditions, the specifications and alloys of the air conditioning foil are relatively simple, which is in the interests of high-volume manufacturing. The market, however, is very seasonal and presents challenges to manufacturers: demand is high in high season but virtually zero in off-season, making production planning complex.

The market and industry in China

In recent years, with strong domestic demand, the production capacity and technical level of air conditioning foil in China have improved significantly. A variety of enterprises have entered the market, operating at all sizes from large to medium and small scale. Some of the leading companies, including North China Aluminum and Bohai Aluminum, have achieved product quality at an international advanced level. However, the potential for excess production capacity makes it a highly competitive market. Manufacturers must be efficient during periods of low demand and meet the high seasonal demand peaks.

Cigarette Packaging Aluminum Foil

Our country is the world’s largest cigarette production and consumption power, in which now our country has 146 large-scale cigarette factories, yearly production of 34 million large size of cigarette box, used mostly cigarette foil packaging, 30% by spraying foil, 70% use rolling aluminum foil, aluminium foil rolling consumption of 35000 tons, as people’s rising awareness on health and imported cigarettes,

The growth of cigarette foil demand has slowed down progressively significantly and is expected to increase slightly in recent years. 70% of China’s double-zero foil is cigarette packaging foil. At present, there are two or three domestic corporations that are able to produce high-quality tobacco foil; the technical level is on par with the international level, but the overall quality of domestic tobacco foil is slightly behind the international level.

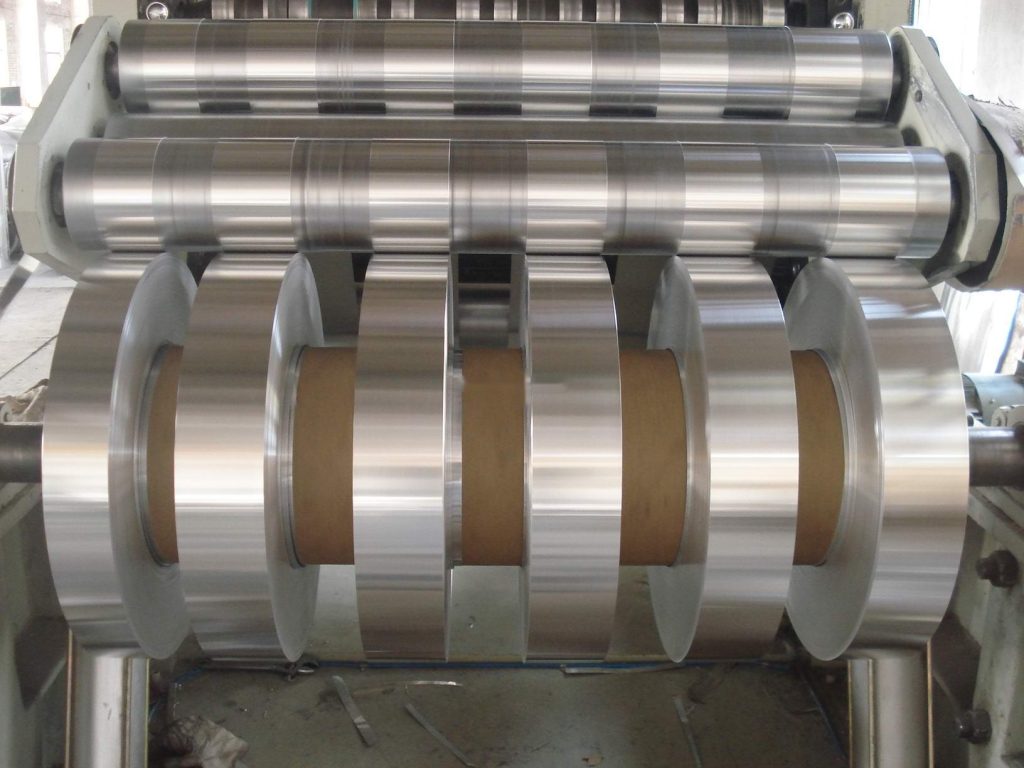

Cable Aluminum Foil

Cable foil is an aluminum composite foil composed of plastic film on one or both sides, which is used as the shield of the cable by taking advantage of the airtight and shielding property of aluminum foil. Cable foil requires less oil on the surface, no holes, high mechanical properties, the overall quality is not high, but the length is very strict.

Decorative Aluminum Foil

Decorative foil is a decorative material applied in the form of an aluminum-plastic composite, which takes advantage of the characteristics of good coloring and high photothermal reflectivity of aluminum foil. Mainly used for construction, furniture decoration, and part of the gift box packaging. The application of decorative foil in China’s construction industry began in the 1990s, and it has spread rapidly from Shanghai, Beijing, Guangzhou, and other central cities to all parts of the country. In recent years, the demand has increased sharply. It is generally used as decorative materials for the inner wall of buildings and indoor furniture, and is also widely used in the facade and interior decoration of commercial institutions.

Decorative foil has the advantages of heat insulation, moisture-proof, sound insulation, fire protection and ease of cleaning, and the appearance of luxury, convenient processing, construction, and installation speed. At present, China’s construction, home decoration industry has formed a decorative foil application boom. With the rapid development of China’s construction industry and the continuous popularity of decorative foil application, decorative foil demand will increase greatly. In addition, the use of decorative foil packaging gifts is very popular in foreign countries. In recent years in China’s rapid development speed is expected to have a better prospect.

Chongqing Lanren Aluminium Co., Ltd was established in 2008, and is a professional manufacturer of aluminium material and aluminium cookware. And we have the whole line to produce aluminium coil and circles, and aluminum cookware.