Surface Treatments and Coatings for Aluminum Circles

Aluminum circles are widely used in various industries. When used, in order to improve their performance and life, aluminum discs usually need to be properly treated and coated. This article explores the surface characteristics of aluminum discs, the available treatment and coating options, and guidance on how to choose the right solution for your needs.

Overview of Aluminum Surface Properties

Aluminum is a versatile metal that is widely utilized in diverse industries due to its outstanding chemical and physical characteristics. But, knowing the characteristics of its surfaces is essential to optimize performance for specific areas. Aluminum’s most significant surface characteristics are:

- Natural Corrosion Resistant: Aluminum is a thin layer of oxide in the presence of air. It provides an inherent shield against corrosion and rust.

- Aluminum is lightweight and durable. Its low density makes aluminum an ideal choice in applications in which weight reduction is essential and its surface may be treated for increased durability.

- Electrical and Thermal Conductivity Aluminum is a great conductor of heat and electricity, which makes it ideal for cooking, electronics and other energy uses.

- Surface Softness: Though it’s easily shaped and formed the aluminum surface, it is vulnerable to damage and wear needing protection.

- Aesthetic versatility: The natural reflectivity and luster is able to be enhanced or modified with treatments that provide an array of aesthetic choices.

- Food Safety: With the right processing, aluminum is not toxic and is safe to use in food grade applications such as food packaging and cookware.

Even with these advantages however, aluminum surfaces that are not treated can be vulnerable to environmental elements such as wear and tear, as well as wear and. Correct surface treatments and coatings are necessary in order to maximize its potential and guarantee long-term efficiency.

What are the Types of Surface Treatments for Aluminum Circles?

Surface treatments enhance the properties of aluminum circles, such as durability, corrosion resistance, and aesthetics. Below is a summary of the key surface treatments and their benefits:

| Treatment Type | Description | Key Benefits | Common Applications |

| Anodizing | Electrochemical process that thickens the natural oxide layer. | Corrosion resistance, wear resistance, and dyeability for coloring. | Cookware, decorative panels, electronics. |

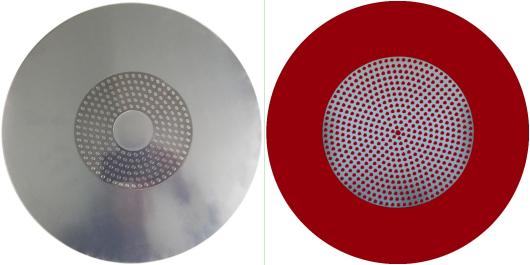

| Polishing | Creates a smooth, reflective surface using mechanical, chemical, or electrochemical methods. | Enhances aesthetics and reduces surface defects. | Decorative applications, reflectors. |

| Etching | Chemical or mechanical process to create a matte surface or improve coating adhesion. | Reduces reflectivity and prepares surface for further coating. | Low-gloss finishes, industrial parts. |

| Chemical Conversion Coatings | Involves chromate or phosphate treatments to enhance surface properties. | Improves corrosion resistance and serves as a primer for coatings. | Automotive, aerospace, general coatings. |

| Brushing | Produces a uniform textured finish through abrasion. | Adds decorative texture and masks minor surface imperfections. | Home appliances, architectural panels. |

These treatments offer specific benefits depending on the intended application, ensuring that aluminum circles meet performance and aesthetic requirements effectively.

What are the Coating Options for Aluminum Circles?

Coatings enhance the performance and appearance of aluminum circles, offering protection against corrosion, wear, and environmental factors. The main coating options include:

| Coating Type | Key Features | Common Applications |

| Powder Coating | Durable, scratch-resistant, and environmentally friendly. Available in many colors and finishes. | Cookware, automotive, architectural. |

| Paint Coatings | Offers aesthetic versatility with various finishes and functional properties like heat or weather resistance. | Marine, automotive, and industrial applications. |

| Anodized Coating | Thickens aluminum’s oxide layer for enhanced durability, corrosion resistance, and color options. | Decorative panels, industrial components. |

| Non-stick Coatings | Provides a non-stick surface; includes PTFE and ceramic coatings. Heat-resistant and easy to clean. | Cookware, bakeware. |

| Electroplating | Applies a metallic layer (e.g., nickel, chrome) for added wear resistance and aesthetic appeal. | Decorative items, luxury products. |

| Anti-corrosion Coatings | Specialized coatings like fluoropolymer or epoxy to protect against harsh environmental conditions. | Marine, automotive, industrial applications. |

This concise format provides a clear comparison of each option’s features and applications, making it easy to understand their suitability for different purposes.

How to Choose Your Treatment or Coating for Aluminum Circles

Choosing the appropriate surface treatment or coating for aluminum circles is a critical decision based on specific application requirements and conditions. Below are the most important factors to consider when selecting the best treatment or coating for your aluminum circles:

Know Your Application Purpose

- Cookware & Food-Related Products: For applications in the kitchen, such as cookware, food storage, or food processing, the treatment or coating must be non-toxic and food-safe. Coatings like non-stick (PTFE or ceramic coatings) are often preferred for easy cleaning and resistance to high temperatures. These treatments ensure safety and performance in cooking environments.

- Automotive & Aerospace: In the automotive and aerospace industries, aluminum circles require coatings that provide exceptional strength, corrosion resistance, and the ability to endure extreme temperatures. Powder coating and anodizing are ideal choices, offering durability, long-term protection, and a sleek, polished finish.

- Decorative & Architectural Uses: For decorative and architectural applications, such as panels, cladding, or lighting, aesthetic appeal is paramount. Anodizing enhances the visual appeal with a glossy, metallic finish, while powder coating offers a wide range of colors and textures. Brushed finishes are also favored for their elegant, matte appearance.

Consider the Environmental Exposure

- Corrosion Resistance: When aluminum circles are exposed to moisture, salty air, or chemicals, it’s crucial to select a treatment that enhances corrosion resistance. Anodizing forms a thick oxide layer that acts as a protective shield against rust, while chemical conversion coatings, such as chromate or phosphate, offer added protection in harsh environments.

- Heat Resistance: For aluminum circles used in high-temperature settings, such as industrial equipment, non-stick or ceramic coatings are ideal. These coatings are designed to withstand extreme heat without breaking down, making them perfect for cookware or high-performance machinery.

- UV and Weather Resistance: For aluminum exposed to outdoor elements, including UV rays and severe weather, powder coatings are often the optimal choice. These coatings are highly resistant to fading, chalking, and degradation caused by UV exposure, making them well-suited for exterior architectural applications.

By Your Aesthetic Requirements

- shiny and reflective finishes: For applications that require a reflective or shiny surface, anodizing is the best option. The process does not just enhance the shine of aluminum but also enhances the durability of aluminum, making it less prone to scratching and oxidation. The most common applications are the consumer electronics industry and other products in which aesthetic appeal is essential.

- Customized colors and textures: Powder coating can provide an array of colors and texture choices, from glossy to matte. The versatility of the coating makes it perfect to use on products that need particular brand colors or design concepts, like those in the consumer or furniture products industries.

- Matte, Subtle Finishes: For a more elegant or polished appearance, etching or brushing techniques can be used. They create a consistent texture that gives a minimalist appearance. It is great for decorative or architectural elements that must be able to blend in with the surroundings.

Requirements for Durability and Wear Resistance

- High Abrasion Resistance: Aluminum-based circles that are subjected to intense wear or scratching, like in industrial and automotive uses, coatings like electroplating (nickel or chrome) or powder coating offer additional protection. They increase the resistance of the surface to dents, scratches as well as other stresses on mechanical.

- Long-term Durability: In applications that need more performance, even in the most demanding of environments, anodizing provides durable protection as well as increased longevity. It is resistant to peeling, chipping, and fading. This makes it suitable for goods that require long-term usage.

- Easy Maintenance Coatings, like nonstick (for cookware) or powder coatings, not only provide long-lasting durability, but they also aid in cleaning and maintenance. The coatings are resistant to staining accumulation, and contamination, which makes them ideal for use that requires hygiene and cleanliness, for example, for food processing.

If you consider these crucial elements, you’ll be able to make the right choice in choosing the best surface treatment or coating for your aluminum circles.

Need to Find An Aluminum Circle Manufacturer?

If you’re looking for a reliable aluminum circle manufacturer, Lanren Aluminium is a good choice. With over 15 years of experience, we are a leading supplier in the aluminum industry, specializing in high-quality aluminum products including circles, sheets, and cookware.

We offer a comprehensive range of products and services, ensuring consistent quality and customized solutions. Our advanced production facilities and skilled workforce allow them to meet diverse industry needs, from food-grade aluminum circles to high-performance applications.

For more information or inquiries, visit our website at Lanren Aluminium.