Anodized vs. Color Coated Aluminum Circles: Which is Better for Your Cookware Needs?

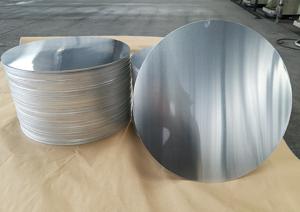

In the kitchenware industry, aluminum is the most popular choice of cookware makers and cooks at home. Its incredible thermal conductivity assures uniform heating. Additionally, its low weight allows the pans and pots to be moved around. These qualities make aluminum circles an essential part of the production of kitchenware. However, as technology advances two newer versions have…