Choosing Between Raw and Finished Aluminum Disks for Your Project

Aluminum disks are preferred across various industries, such as automotive and aerospace, home appliances, and construction. The decision between raw and finished aluminum disks for your application involves one that balances the differences, benefits, and drawbacks. This is a compendium on the differences, benefits, and drawbacks of raw and finished aluminum disks to enable an efficient decision.

What Are Raw Aluminum Disks and Finished Aluminum Disks?

Raw Aluminum Disks

Raw aluminum disks are unfinished aluminum rounds or sheets that have been processed into a disk form but not further refined or finished. Raw aluminum disks are in their most basic form and are characterized by the following features:

- Untreated Surfaces: Raw aluminum disks typically have rough surfaces that may contain cuts, stamps, or extrusion marks. They lack polish or coatings, and the edges are sharp.

- Highly Versatile: Natural raw aluminum disks are simple to machine, polish, or otherwise alter. They are a comprehensive starting point for projects that require intricate designs or specialized finishes.

- Versatility of Production: The discs can be used for applications with special, tailored specifications. Their versatility has placed them as the preferred choice for custom machining, drilling, and other alterations among industries and do-it-yourself projects.

- Common Uses: Aluminum raw disks are widely used in aerospace, automotive, and manufacturing. They are often used for prototype work, making specialty parts, or as a material for additional finishing processes.

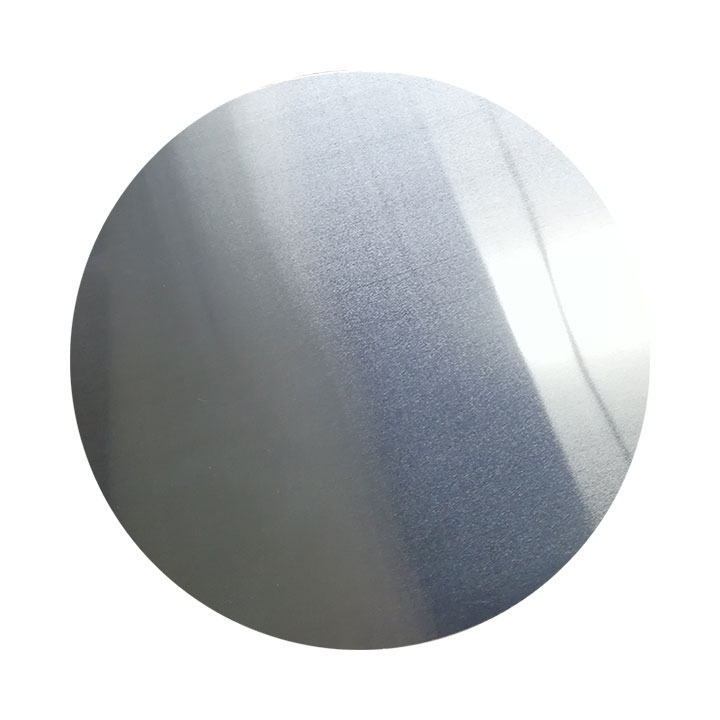

Finished Aluminum Disks

Finished aluminum disks, however, have undergone specialized treatments to further improve their properties, looks, and function, and are now ready for use, such as coated aluminum disks, mill finished aluminum disks. Such disks typically have:

- Smooth and Polished Surfaces: Finished aluminum disks typically have polished, anodized, or coated surfaces to provide a smooth, pleasing finish. The edges are rounded or deburred, both for safety as well as for aesthetic reasons.

- Pre-Processed Features: These disks may be anodized to enhance corrosion resistance, coated to provide improved durability, or painted for visual appeal. These processes not only render the disks usable but also provide a finish in appearance and durability from environmental elements.

- Consistency and Accuracy: Since they have been pre-processed, completed aluminum discs provide consistency in their appearance, size, and shape. This makes them suitable for utilization in applications calling for high accuracy, such as those in the automotive, consumer electronics, and architectural sectors.

- Common Uses: Finished aluminum discs are used broadly in industries that require appearance, a long-lasting nature, and a readily available supply. They are mostly applied to uses such as decorative items, auto components, electric boxes, and other products that may not require much or any further modification.

Raw Aluminum Disks vs. Finished Aluminum Disks

The choice between raw and finished aluminum disks depends on various factors, such as cost, project specifications, and the degree of customization required. Below is a comprehensive comparison of raw and finished aluminum disks across key criteria to help you determine which option best meets your needs:

| Aspect | Raw Aluminum Disks | Finished Aluminum Disks |

| Cost | Raw aluminum disks are typically more affordable as they require minimal processing, making them a cost-effective option for those on a budget. | Finished disks are more expensive due to the additional treatments, coatings, or machining they undergo. |

| Processing | Raw disks require further processing, such as machining, polishing, or coating, to meet specific project needs. They offer flexibility but demand more time and resources. | Finished disks come pre-processed and ready for use. Their surface treatments or precision machining are done during production, saving time during implementation. |

| Customization | Raw disks offer high customization potential, allowing for modifications in shape, size, and surface treatment, depending on the project requirements. | Finished disks offer limited customization since they come with pre-existing surface finishes and dimensions. Customization is more challenging after the disk is processed. |

| Durability | Raw aluminum disks may require additional treatments (e.g., anodizing or coating) to improve their durability and resistance to corrosion. | Finished disks often have enhanced durability with built-in protective coatings or anodizing, making them more resistant to environmental wear. |

| Appearance | Raw aluminum disks typically have a plain, industrial appearance, suitable for applications where aesthetics are not the primary concern. | Finished disks come with polished, anodized, or powder-coated surfaces, making them more visually appealing for projects where aesthetics matter. |

What to Consider When Choosing Between Two?

Choosing between raw and finished aluminum disks comes down to a few important factors that will impact your project. Here’s what you should think about:

Choosing between raw and finished aluminum disks comes down to a few important factors that will impact your project. Here’s what you should think about:

- What You Really Need: Start by considering the specific requirements of your project. Should you plan to do heavy customizing, e.g., machining, cutting, or welding, raw aluminum disks offer the flexibility to shape to size. However, should you need a product that is ready to be used with minimal additional effort, finished disks will be more convenient and time- and labor-saving.

- Your Budget: Raw aluminum discs tend to be less expensive since they require little or no processing. However, if you are going to take time to do things such as polishing or protective coatings, the cost begins to add up quickly. Finished discs are more expensive initially, but may be more budget-friendly in the end when taking into account the time and resources saved by not needing to do extra work. Think about your budget and if the convenience of using ready-made disks is worth paying more.

- Durability and Protection: If your disk is going to be exposed to harsh conditions, like outdoor elements or corrosive environments, finished disks may be a better option. Processes like anodizing or powder coating offer extra protection and extend the life of the material. Raw disks won’t have this built-in protection, so you’d need to treat or coat them afterward if needed, which adds time and cost.

- How It Looks: If the aluminum disk is going to be part of a visible product—maybe for a consumer item or a design piece—you’ll likely want it to look polished and professional. Finished aluminum disks come ready with a sleek, clean surface that gives a high-quality finish. Raw disks have more of an industrial look and might need extra work to meet aesthetic standards.

- Time: Lastly, consider your project timeline. If you’re working under a tight deadline, finished disks are a better option as they are ready for immediate use. Raw disks, on the other hand, may require extra time for adjustments or treatments, potentially causing delays.

By weighing these factors, you can make an informed decision based on what’s most important for your project, whether it’s cost, time, appearance, or durability.

To Sum Up

Raw aluminum disks offer more flexibility and are cost-effective, making them a great choice for projects that require customization or further processing. On the other hand, finished aluminum disks save time and effort, offering enhanced durability and a polished look, which makes them ideal for projects where quick turnaround, performance, and aesthetics are essential.

By weighing the pros and cons of each option and aligning them with your project goals, you can make a well-informed decision. Whether you need the adaptability of raw aluminum disks or the ready-to-use features of finished ones, selecting the right manufacturer will ensure the success and efficiency of your project. If you are looking for a reliable aluminum disk supplier, Lanren will be your first choice. Contact us to learn more information!

Related Products