The Importance of Customization in Aluminum Discs for Specific Industry Uses

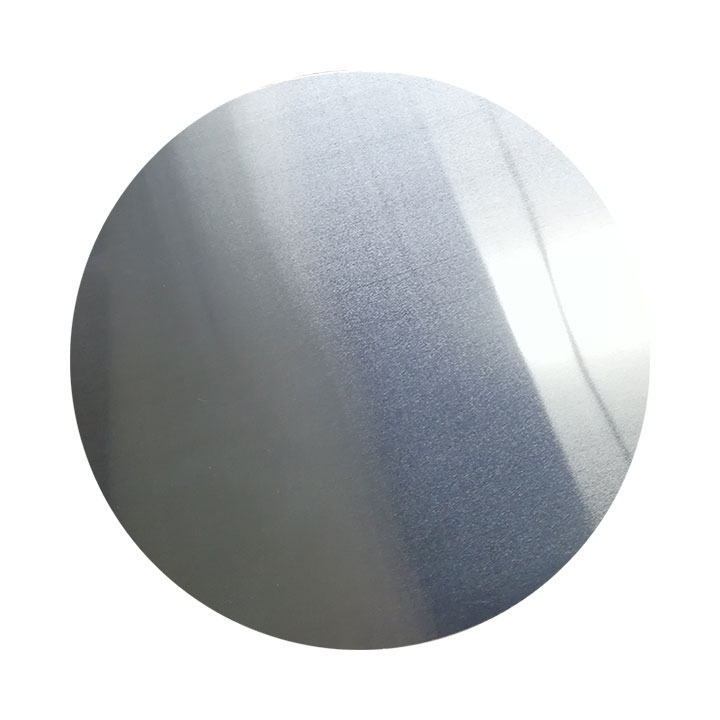

Aluminum discs or aluminium circles are common components used in most industries, such as the automotive industry, aerospace industry, cookware, and electronics. They are corrosion-resistant, light in weight, and have high thermal conductivity, and hence are most suitable for most applications. However, the application of aluminium discs is usually dependent on the ability of aluminium discs to satisfy some conditions, and hence the tailorability of aluminium discs becomes extremely important.

Reasons to Opt for Aluminum Discs

Aluminum discs are valued in many industries for their remarkable characteristics and affordability.

- Aluminum discs are especially beneficial for the automotive and aerospace industries, where lightweight materials are critical because they are lightweight and offer impressive durability. These discs also resist wear and maintain their structural integrity under challenging circumstances.

- Due to the oxide layer that forms on their surface, aluminum discs also demonstrate remarkable self-protection and environmental durability in a variety of situations. These situations can involve aluminum discs in industrial equipment or even cookware.

- Aluminum discs are also thermally and electrically conductive, thus can assist in applications that involve heat transfer and electrical performance.

- Aluminum is particularly cost-effective and sustainable, especially when considering that it is abundantly available, easily recyclable, and used on a large scale.

These qualities make aluminum discs an indispensable material for manufacturers seeking efficiency and performance.

Significance of Tailoring Aluminum Discs

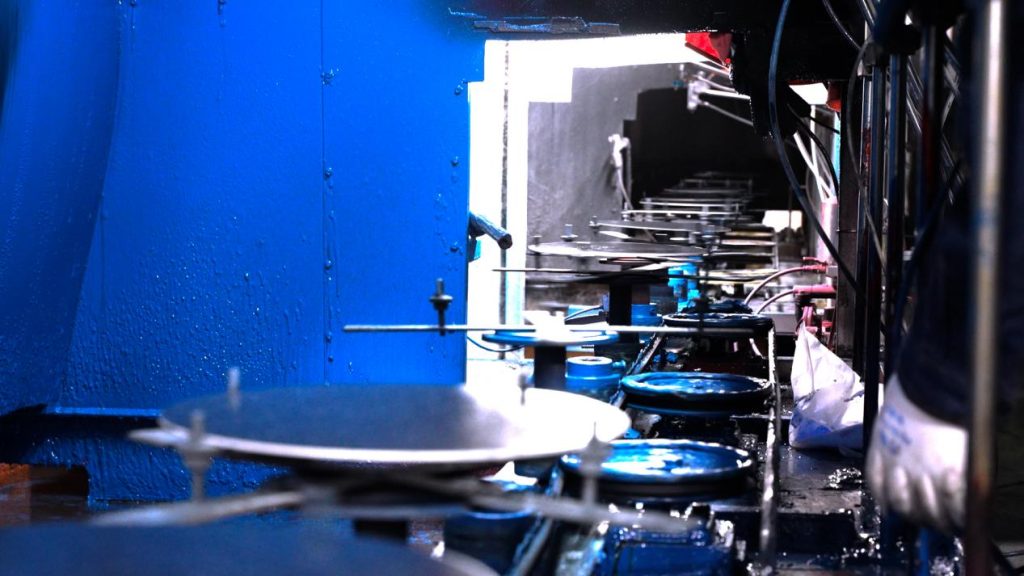

Customization helps provide the ideal aluminum discs for different applications since each industry has very particular needs. Off-the-shelf discs are often imprecise and inefficient for more demanding jobs. Custom discs for each application provide numerous advantages:

- Increase in Efficiency: Custom designs mean better integration with the machine or product, lowering operational downtimes and increasing operational efficiency.

- Greater Durability: Discs can be coated to withstand corrosion, wear, and severe environmental conditions, thus increasing longevity.

- Enhanced Function: Alterations to dimensions, geometry, and surface finish will influence and promote desirable heat and electricity transfer, interstructural stiffness, and other fundamental functions.

- Economic Efficiency: While tailored discs require higher upfront expenditures, they tend to save money in the long run. Their longevity and efficient performance significantly reduce maintenance, material wastage, and the need for replacements, thus saving costs on repetitive expenditures.

Tailored aluminum disks are essential if businesses want flexibility alongside meeting innovation, along with rigorous standards, as well as optimized structural attributes

Essential Customization Features for Aluminum Discs

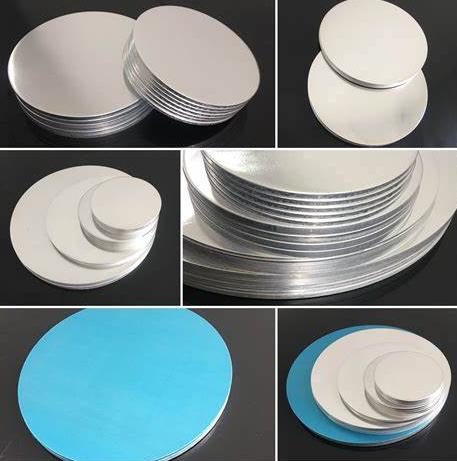

Customizing aluminum discs involves adjusting several key features to ensure optimal performance for specific applications. These features include:

| Customization Feature | Description | Benefits |

| Material Composition | Adjusting the alloy blend to meet specific strength, flexibility, or conductivity requirements. | Tailors the mechanical properties of the disc, such as increased strength, improved corrosion resistance, or enhanced thermal conductivity. |

| Dimensions and Tolerances | Modifying the size, thickness, and shape of the disc to meet precise specifications. | Ensures a perfect fit for various applications, eliminating compatibility issues and ensuring optimal performance in machinery or devices. |

| Surface Treatment | Applying coatings or finishes, such as anodizing, powder coating, or polishing, to the aluminum disc’s surface. | Improves durability, enhances corrosion resistance, and provides aesthetic finishes that suit the specific environmental or aesthetic requirements. |

| Perforations or Grooves | Introducing holes, slots, or grooves into the aluminum discs for specific functional purposes, such as improved airflow, lightness, or heat dissipation. | Custom perforations or grooves improve the functionality of the disc, such as better cooling in heat exchangers or lighter weight for automotive parts. |

| Edge Modifications | Shaping or smoothing the edges of the disc to meet safety or assembly requirements. | Enhances safety by removing sharp edges and ensures compatibility with automated or manual assembly processes. |

By adjusting these features, you can create aluminum discs that are perfectly suited to your applications, enhancing performance, longevity, and efficiency.

Industries Benefiting from Customized Aluminum Discs

Across various fields, tailored aluminum discs bring considerable benefits.

- Automotive Industry: In automotive engineering, aluminum discs are used in the wheels and body panels of vehicles as well as in engine parts. Meeting Custom performance, strength, and weight requirements for these discs boosts fuel economy and enhances overall vehicular performance.

- Cookware: Preservatives include frying pans and pressure cookers, which contain aluminum discs. Uniform heat distribution during cooking is achieved through custom-thick non-stick coating, improving durability, and protective layers added to withstand high temperatures over extended periods of time.

- Aerospace: Aluminum requirement in aerospace components is stringent for specifications approvals for strength-to-weight ratio, tailored components must be able to endure extreme conditions while lightening the aircraft framing.

- Electronics: Tailored specifications make excessive component wear obsolete, prolonging device life, efficiency guarantees maximum thermal conductivity, retaining efficiency enables precise device operation versatile customized aluminum offered within means.

- Manufacturing: Precision performance needs bespoke sizes alongside set specs./manufacturing processes integrated, such as machining or stamping, strive for optimal output, ensuring holistic seamless execution

Conclusion and Key Takeaways

Customizing aluminum discs is more than producing more than standard components; it makes them high-performance, mission-critical instruments that are specifically crafted to withstand the individual requirements of various industries. Custom solutions provide unmatched efficiency, durability, and performance for operational applications.

The key is that the alloy and type of alloy should match the use purpose, as well as the diameter and surface treatment. With more innovations developed by various industries, there will be an increasingly greater demand for customized aluminum discs, and they will continue to establish themselves as the foundation of industrial versatility and productivity. Wholesale adjustable aluminum discs are available if you want them; you can contact Lanren at will.

Related Products