Are Non-Stick Coated Aluminium Disks Better than Traditional Cookware?

The choice of material is extremely significant in affecting the way a product performs and lasts, and consequently impacts the satisfaction of the end-users in the rapidly changing landscape of the cookware industry. Among the multiple innovations in cookware materials, non-stick coated aluminum disks have obtained much attention in the last few years. In a situation where makers and suppliers of cookware endeavor to meet consumer needs, are the non-stick aluminum disks significantly advantageous over traditional cookware options?

What are Non-Stick Coated Aluminium Disks?

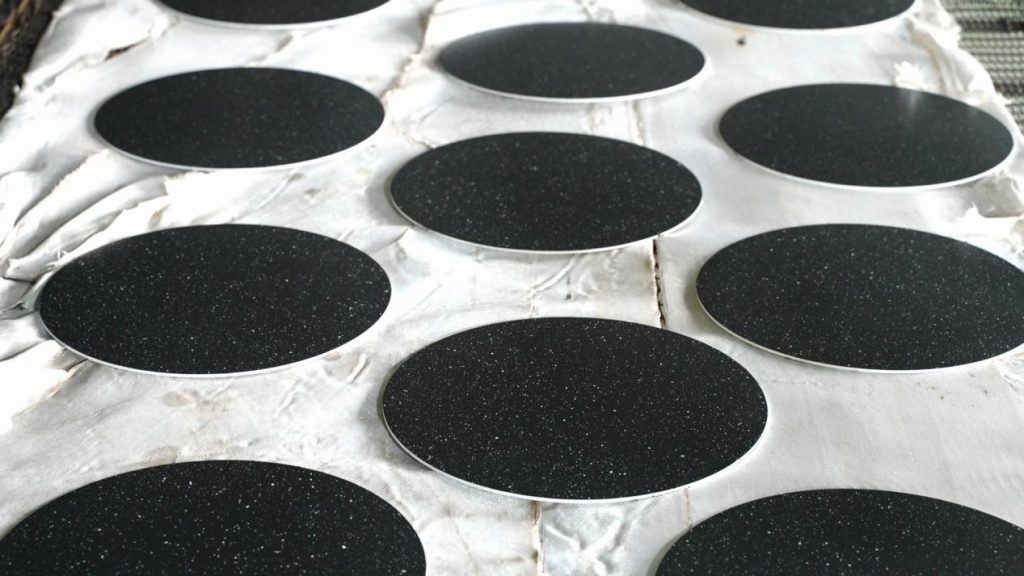

Non-sticky coated aluminum wafers are the most advanced components used in the manufacturing of kitchenware, characterized by their lightness and toughness. They are made of high-grade Aluminum which has a deserved reputation for its superior heat conductance, allowing the cookware to get hot quickly and evenly. A coating material is applied to the aluminum in the form of non-stick coatings to protect the surface, thereby allowing easy food removal during the cooking process.

The non-stick-coated surface cleans kernel shells, reducing the payout due to excessive oils or fats used for cooking. Healthier cooking comes in handy with this specific feature. Moreover, the nonstickiness justifies the good cleaning it affords, say, pale food residue removed quite easily and hence without the geometrical scrub-fest. The variety of kitchen utensils this aluminum tastes in includes frying pans, griddles, and woks, which warrant an efficient and long-term answer for kitchens at both professional and home-cooked levels!

A Quick View of Traditional Cookware

Traditional cookware consists of different classes of materials, having peculiar backgrounds and applications. The choice of material often influences its cooking performances, durability, maintenance, and the general experience of the user. With this considered, it is ensured that with only vaguest kind of analogy, using this information to state that both copper and cast iron are heavy. The essential properties of the classic materials used for cookware would well distinguish a ceramic material from a stainless-steel one.

Here is a detailed analysis of each material:

- Cast Iron: This material is something that has been giving its charm, particularly because of its superb heat capacity and heat dispersion, allowing remarkably controlled cooking. It is most preferred for slow-cook foods and searing, thanks to its equally dispersed heat release. Moreover, hate the fact that cast iron cookware should always be seasoned and has the potential to rust immediately. If not given proper attention, it deteriorates and needs rather high maintenance.

- Stainless Steel: Stainless steel are very durable, corrosion-proof materials which show a lot of versatility as well as a very modern and stylish look. The same as the other steel alloys, stainless steel is also non-reactive to outside elements in general and very much so to food. One of the drawbacks of stainless steel is that it is not as good a conductor of heat as aluminum, and a pan made of this material may give you a very unevenly heated meal, which could be an annoying thing to overcome. The other side of the coin is that stainless steel is easier to take care of than cast iron, yet it is not that maintenance-free and needs some work apart from washing.

- Copper: Copper pots and pans have long been appreciated for their high heat conductivity and precision in controlled cooking, not to mention that they look beautiful and elegant, too. Cooking in copper, however, is really costly, and copper cookware does require extensive maintenance that regular polishing can only do so well. On the other hand, copper is very susceptible to scratches and reacts with acid, and copper utensils should not be used in cases where the food is acidic, unless some other material, e.g., stainless steel, was used to line the cooking surface.

- Ceramic: Ceramic pots and pans give a non-stick coating that is natural and free of any man-made chemicals. It is a top pick among those who are health-conscious. But still, it cannot outlast the non-stick quality of aluminum, and it is easier to break or chip. Moreover, the coating of the ceramic ware, which is non-stick and that people love, can disappear over time, thus it needs proper maintenance.

While traditional cookware materials are renowned for their longevity and ability to withstand high temperatures, they often require more attention in terms of maintenance and care. Additionally, many of these materials do not offer the same level of convenience in cooking and cleaning as non-stick alternatives, making non-stick coated aluminium disks an attractive option for modern cookware solutions.

Non-Stick Coated Aluminium Disks vs. Traditional Cookware

Now, let’s look at the key differences between non-stick coated aluminium disks and traditional cookware materials, such as cast iron, stainless steel, and copper. A comparative table is provided to highlight the advantages and disadvantages of each material in terms of cooking performance, maintenance, durability, weight, and price.

| Criteria | Non-Stick Aluminium Disks | Traditional Cookware |

| Cooking Performance | Excellent heat conductivity, quick and even heating Non-stick coating reduces the need for oil and minimizes food sticking | May have uneven heating (e.g., cast iron, stainless steel) May require more oil or fat to prevent food from sticking |

| Maintenance | Easy to clean due to non-stick surface Can be wiped clean with minimal effort | Requires more maintenance (e.g., seasoning for cast iron, polishing for copper) May require scrubbing and special care (e.g., rust prevention for cast iron) |

| Durability and Longevity | Durable, but the non-stick coating may degrade over time Typically lasts 5–10 years depending on usage and care | More long-lasting, especially materials like cast iron and stainless steel Cast iron can last generations with proper care, stainless steel and copper have long lifespans |

| Weight | Lightweight and easy to handle Convenient for everyday cooking and storage | Heavier, especially with materials like cast iron and copper Can be cumbersome, requiring more strength to handle |

| Price Point | Generally more affordable Offers a good balance of performance and cost-effectiveness | Can be more expensive, especially high-end options like copper and enameled cast iron High-end cookware like copper or premium cast iron can be costly |

This comparison highlights the advantages of non-stick aluminium disks in terms of ease of use, cooking efficiency, and maintenance, while also acknowledging the long-lasting durability and performance of traditional cookware materials.

Where to Buy Non-Stick Coated Aluminium Disks?

It is a must that the manufacturers and sellers of kitchenware, who, among other things, are after the highest quality non-stick coated aluminum disks, establish relationships with trusted suppliers able to supply consistent, reliable products with on-time deliveries.

One such reliable partner you can trust is Lanren Aluminum – a seasoned producer specializing in first-rate aluminum products that are not only superb in terms of quality but also have non-stick aluminum disk as an option. With our expertise in the manufacturing of robust, efficient, and eco-friendly materials for the cookware sector, we have become a natural ace in the industry. Lanren Aluminum also has a variety of non-stick coatings to choose from, thus enabling manufacturers to produce products that are specifically tailored to their markets. The non-stick aluminum disks of Lanren Aluminum have different dimensions and gauges to cater to different cookware applications and are suitable for the likes of frying pans, woks, griddles, etc.

Please, check our website for more aluminum products: lanrenaluminium.com

Related Products