How Aluminum Utensils Are Made?

Aluminum utensils are widespread in everyday use, ranging from kitchen utensils such as pots and pans to particular containers in industrial applications. The properties of aluminum, namely being light in weight, having high thermal conductivity, and certain corrosion resistance, render it a useful material for making utensils. The production of aluminum utensils involves a series of steps comprising careful raw material selection, application of multiple modes of manufacturing, and final polishing and packing. With the application of several complex and well-fitted procedures, aluminum is ultimately transformed into a variety of useful and decorative utensils meant for everyday use.

Raw Materials and Preparation

Production of aluminum cutlery begins with the selection of the right aluminum. Pure aluminum (99.5% or more) is most commonly utilized owing to its excellent heat conductivity and lower weight. Aluminum alloys, where aluminum is combined with a bit of another metal like magnesium or silicon, are also utilized owing to their added strength and durability.

Some of the more popular aluminum alloys used to make utensils include the following:

- 1100 Aluminum Alloy: The aluminum content is greater than 99%. Extremely resistant to chemical reactions thus safe for food contact.

- 3003 Aluminum Alloy: Manganese is added to provide greater resistance to corrosion and omnidirectional formability. Adaptable to cookware and kitchen utensils and very lightweight.

- 5052 Aluminum Alloy: Excellent resistance to corrosion, especially for marine environments. Increased strength and durability make this grade of aluminum suitable for heavy-duty cookware.

The selection is based on a combination of elements including, strength, corrosion resistance, heat conductivity and ease of fabrication.

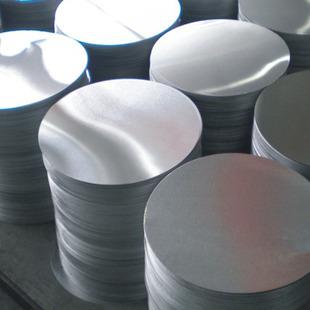

Aluminum is generally purchased as thick sheets or in the form of ingots. For the sake of the environment, recycled aluminum is used. The cleaning and inspection of aluminum is a prerequisite for the manufacturing process. The manufacturing process of the destination utensils is initiated by melting the aluminum, which is then cast into slabs or billets.

Aluminium Utensils Manufacturing Process

The production of aluminum utensils involves multiple stages, each carefully designed to transform raw aluminum into high-quality kitchen tools. These stages including:

Shaping the Aluminum: Casting and Forging

Casting

Casting is the most common method used for shaping aluminum utensils. Most effective is high-pressure die casting, where molten aluminum alloy is forced into precision dies under high pressure. It is best applied in the manufacture of utensils having complicated patterns, e.g., patterned kitchenware. The dies, normally high-strength steel, are fabricated in two halves that can be opened and closed. The molten aluminum alloy is pushed into the mold cavity under high pressure and solidifies to create parts that are a mirror image of the mold shape. To achieve more freedom in production, sand casting is employed. In this case, a sand mold is developed and the aluminum alloy is cast in it. Sand casting, while being cost-saving and best for small batches, has a tendency to require additional finishing for the required quality.

Forging

Forging involves the application of pressure on aluminum or aluminum alloy billets for plastic deformation. Open-die forging applies basic tools like anvils and hammers to forge billets into basic utensil components. Open-die forging is ideal for the manufacture of basic shapes with low precision requirements. Closed-die forging, on the other hand, uses custom dies to produce intricate and highly precise parts, e.g., ergonomic handles for high-end cookware. Forging compacts the inner structure of aluminum, which makes it stronger and more durable.

Casting and forging are essential methods of aluminum utensil shaping. Each has its own advantages, and both give manufacturers the choice of which method to utilize based on production needs and product specifications.

Adding Functionality: Anodizing and Coating

Anodizing

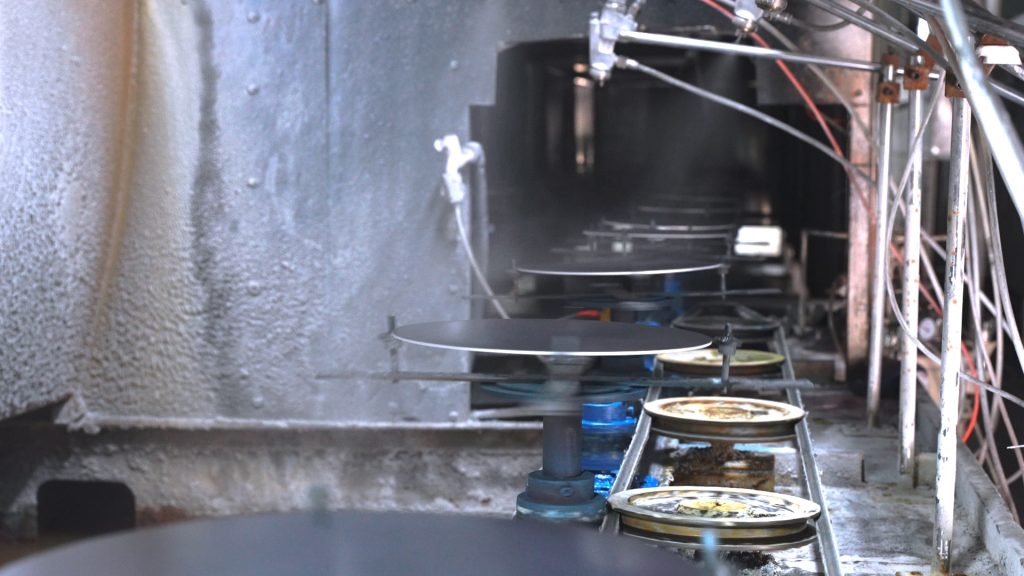

Anodizing is an electrochemical treatment that creates an oxide layer on the surface of aluminum utensils. Utensil anodizing serves as an anode and is immersed in an electrolyte solution, such as sulfuric acid, and a direct current is passed through. Aluminum atoms lose electrons and get oxidized in processing, hence creating a dense layer of aluminum oxide. Electrochemical conditions are maintained to control the thickness of the oxide layer. Not only does anodizing increase wear resistance and hardness, but it also significantly the corrosion resistance. Apart from this, since the layer of anodizing is porous, it is simple to color utensils in various colors and thus make them more appealing.

Coating

Apart from anodizing, aluminum kitchen utensils are normally coated to enhance their functionality. For example, non-stick coatings in the form of fluoropolymers are applied to kitchen utensils. Preparation of the surface is done cautiously in an attempt to create effective adhesion. The coatings give useful characteristics like non-stick property and ease of cleaning, which greatly enhance the performance of the kitchen.

Anodizing and coating add value to aluminumware because they make it more useful, long-lasting, and more attractive in an attempt to meet the requirements of modern consumers.

Finishing Touches: Polishing and Packaging

Polishing

Polishing enhances the surface quality and appearance of aluminum utensils. Mechanical polishing is a common method, using polishing wheels made from soft materials like cloth, combined with polishing compounds. As the wheel rotates at high speed, it smooths the utensil’s surface, removing minor imperfections and reducing surface roughness. For complex shapes, chemical polishing may be used, where aluminum reacts with a chemical solution to produce a smooth finish.

Packaging

The final stage in the manufacture of aluminum utensils is packaging. Each utensil has its own packaging solution. Small utensils are individually wrapped in plastic film and packed in lots, and large cookware is packaged in cardboard boxes with foam inserts so that they do not get damaged in transit. Packaging also serves to protect the utensils but doubles as a highly effective marketing tool by attracting customers with colorful designs.

Polishing and packaging render aluminum utensils not just pleasing to the eye but also well-coated, presenting a quality product to the consumers.

The manufacturing process converts raw aluminum into useful utensils through a chain of precision skills and rigorous quality tests. Every process ensures that the end product is both useful and pleasing to the eye.

A Reliable Aluminum Utensils Manufacturer – Lanren

In the world of quality aluminum utensils, Lanren has distinguished itself as a reliable company for many years. Over the years, Lanren has specialized in the production of numerous types of cookware, which ensures that the cookware is produced in compliance with international regulations.

Commitment to Quality

We ensure quality control of the raw materials, source quality aluminum and alloys from reputable suppliers. Among the many manufacturing processes of components, the company has invested in cutting-edge casting and forging equipment in addition to its extensive capabilities in functional enhancement, such as anodizing, coating, among other processes. For example, the company’s anodizing production line, capable of precise control of the quality and thickness of the oxide layer, produces and colours aluminium utensils and sustains superior corrosion resistance. During the finishing processes, the company, alongside its other partitions like the polishing partition, which achieves smooth surfaces, and the other partitions, produces attractive and functional packaging.

Wide Product Range

Lanren’s product offerings vary from ordinary kitchen utensils to uniquely crafted cookware. Thanks to its innovative approach to product development, the company can expand its product offerings to keep pace with modern kitchen needs.

Producing aluminium utensils is a form of art that integrates technology and science. From procuring aluminium of the highest quality to giving the utensils perfect finishes, every element is pivotal.

Related Products