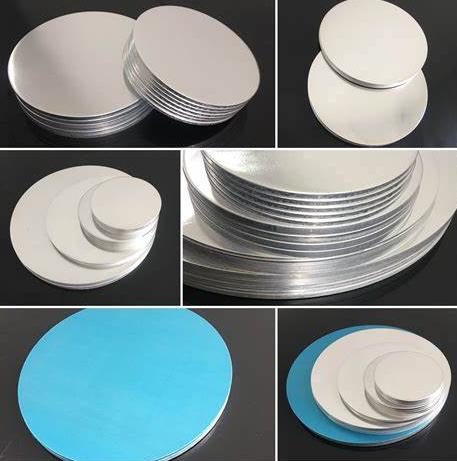

The Importance of Customization in Aluminum Discs for Specific Industry Uses

Aluminum discs or aluminium circles are common components used in most industries, such as the automotive industry, aerospace industry, cookware, and electronics. They are corrosion-resistant, light in weight, and have high thermal conductivity, and hence are most suitable for most applications. However, the application of aluminium discs is usually dependent on the ability of aluminium…