What You Should Know Before Buying Aluminum Circle?

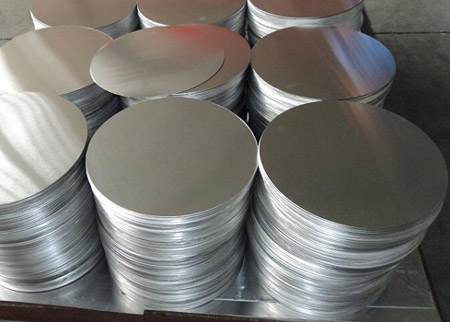

Aluminium circles are extensively used in a variety of industries due to their durability, versatility, and light-weight properties. If you’re a manufacturer, product designer, or supplier seeking to incorporate aluminum circles in your next project, there are many important things to think about prior to buying. Knowing the process of manufacturing and the various kinds of aluminum circles, and the requirements you have will allow you to select the best product. This article will help you make an informed choice in purchasing aluminum circles.

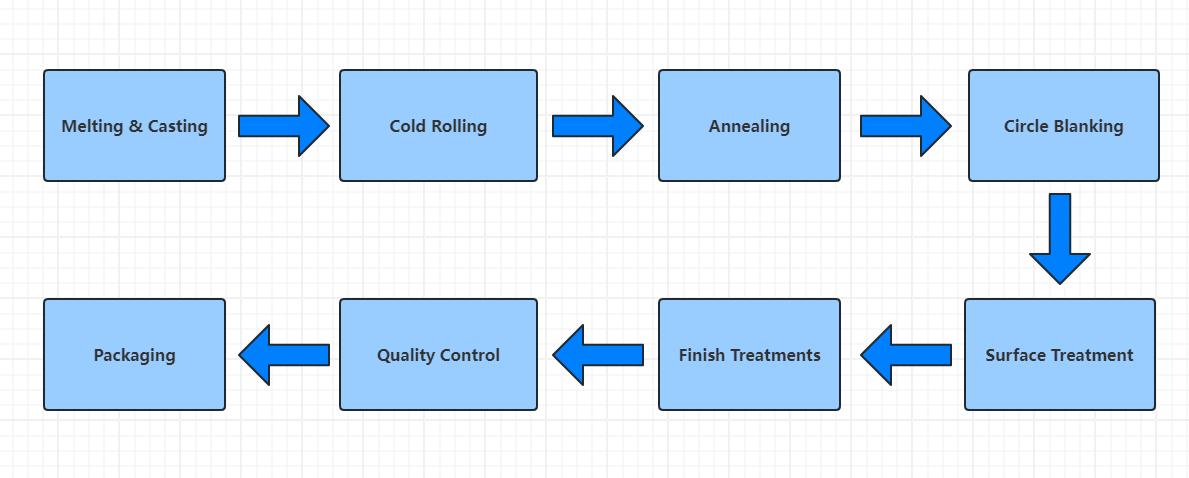

Understand the Aluminum Circle Manufacturing Process

Commercial circles in aluminum are prepared after ensuring the requisite quality is attained as a result of a number of sequential operations. These operations are typically as follows.

- Casting: The process starts with aluminum metal being cast into large slabs or ingots. These ingots serve as the base material used for manufacturing aluminum circles. This step is crucial as it directly impacts the ultimate performance and characteristics of the finished aluminum circles.

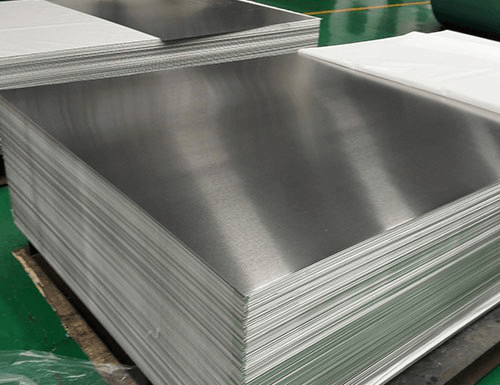

- The rolling process: After the ingots are prepared, the next step involves passing the ingots through a rolling mill. The main objective of rolling is to reduce the thickness of the aluminum. This is done in a manner that allows the structure of the aluminum to be transformed into thinner sheets or coils. These are later cut into aluminum circles.

- Blanking: After the aluminum is rolled into thin sheets, the next step is to create a blank. In this process, the press machine uses a die to cut precise circles out of the sheet. These circles can differ in size and thickness, depending on the requirements for the intended end use.

- The steps of the heat treatment process: Aluminum circles undergo heat treatment processes to increase their mechanical properties, more specifically, their strength and hardness. This consists of heating the aluminum to a required temperature and then controlled chilling it to obtain the pre- characteristics of the aluminum.

- Heat Treatment: Aluminum circles can have different finishes depending on their intended application, including polishing, anodizing, or more. They also finish the aluminum for added resistance to corrosion and for better overall endurance.

Gaining insight into this process will help you understand the quality and performance characteristics of aluminum circles. This will help you select the best aluminum circle for your intended purpose, ensuring that the aluminum circle will fulfill all the specifications required to complete the task at hand.

Know the Types of Aluminum Circle

Aluminum circles can serve a lightly varying purposes. For identifying purposes, uses, the alloys, manufacturing procedure, and the intended uses define the most common types. Here are the most important types of aluminum circles:

Deep Drawing Aluminum Circles:

For deep drawing processes circles made of high-purity soft aluminum alloys (specifically 1050 and 1060 ) can be made. Since they can be stretched and shaped to larger forms and be compressed without breaking, they are highly valued. For heat distribution, soft aluminum alloys are also manufactured to be used in cookware. They are also used in the production of kitchen equipment, most specifically the woks, frying pans.

Spinning Aluminum Circles:

In the spinning process, once the aluminum circle is spun at high speeds, it can be shaped into a hollow circular form. This is how intricate designs can be made. For this purpose, soft alloys that are easy to form and 3003 are sufficient. Sturdy, shaped designs can be used for lamp covers, aluminum containers, and for decorative purposes.

Cookware Aluminum Circles:

These are made for specific kitchen items. They are typically stronger and made of premium 3003 aluminum alloy, which provides greater thermal conductivity and strength. They are the integral circles in the making of thermal retention pans, cookware, and pots which require high thermal retention and corrosion resistance.

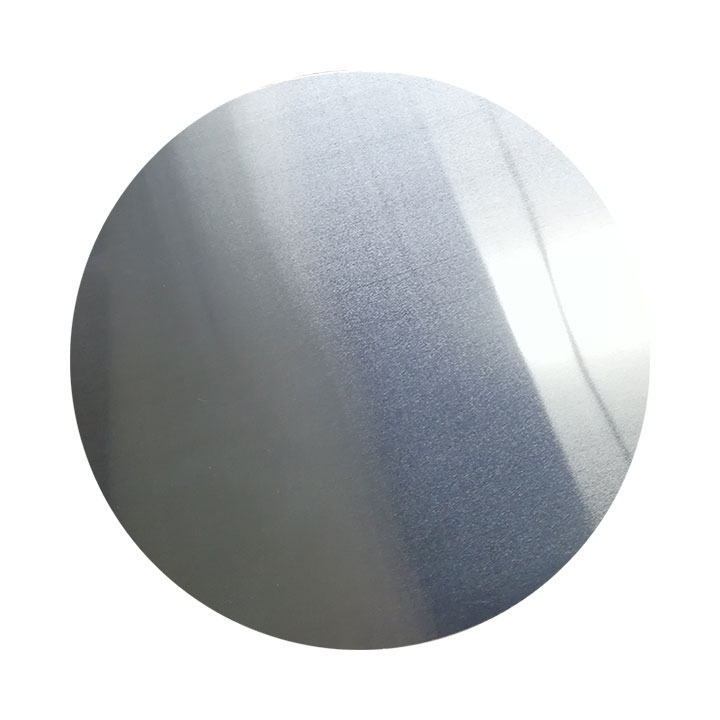

Decorative aluminum Circles:

Used primarily in aesthetic and design applications, decorative aluminum circulars usually have a smooth, polished, or matte surface for visual aesthetics. They are often utilized in decorative interiors and architectural elements in which the appearance of the product is equally important to its function.

Every type of aluminum circle comes with distinct characteristics and advantages, depending on the application. Knowing the differences can aid you in selecting the right solution for your needs.

Determine Your Need Aluminum Circle

Before buying aluminum circles, it is essential to define your requirements in order to ensure that you choose the correct product. Be aware of the following elements:

Alloy and Grade

Aluminum circles can be made in multiple alloys, which determines their toughness, corrosion resistance, strength and flexibility. Some of the common alloys include:

- 1050 and 1060: These alloys are high-purity aluminum. Lightweight applications include household cookware, electronics, and reflectors. Lightweight applications such as these require high durability and corrosion resistance, which these alloys possess.

- 3003: This alloy offers good all-round strength and reasonable corrosion resistance. Because of that, it finds use in the industrial sector for roofing, heating, and the construction of traffic signs.

- 5052 and 5005: These alloys are stronger and offer better corrosion resistance, in particular, for use in the marine environment. Because of that, they are used in the construction of boats, hulls of outdoor structures, and solar panels.

Choosing the correct alloy helps to ensure the aluminum circle will meet the performance requirements of the project with respect to strength and endurance.

Thickness and Size

The size and thickness of an aluminum circle depend on how you plan to use them. There are different requirements for different applications.

- Thinner circles are good for signs and decorations. Hence, they need thin circles which are about 0.2 to 1 millimeter in thickness, and this is good enough.

- Thicker circles in these cases are more than 6 millimeters in thickness. This would also include applications in cookware, parts for automobiles, and industrial components. This is necessary for the durability and efficiency of the product.

Making the right choice is essential. This is to make sure that the thickness, size, and your budget are all in the right proportion. Otherwise, efficiency and cost can be significantly low, which is not ideal.

Surface Finish

The finish on the surface of the aluminum circle affects its appearance as well as performance. The most common finishes are:

- polished surface: For use in applications that require a glossy, smooth surface, like cookware or other decorative items.

- Matte finishes: Often used in signs or industrial applications in which a neutral, non-reflective appearance is desired.

- A nodized surface: For added durability and corrosion resistance, anodizing offers an extra layer of protection that makes it ideal for outdoor and marine applications.

In determining the finish of the surface, take into consideration the environment that the circle of aluminum will be subjected to, and whether aesthetic features are required for your item.

Select an Accurate Aluminum Circle manufacturer

Selecting an aluminum circle manufacturer is one of the most critical decisions you will ever make. Your specifications will only be met if high quality is maintained throughout the entire manufacturing process. Here are some things you must consider when choosing one.

- Good reputation: You’ll need to check the standing of the manufacturer in the market. Customers will tend to speak of the illusions they have about a reputation. Their illusions will be justified if the manufacturer designs products in compliance with their needs.

- Quality Control: The need for quality control in the manufacturing of aluminum circles is undeniable. It must be determined if the manufacturer has an extensive plan for testing and evaluating the results of manufacturing.

- Modifications: Most projects are characterized by the need for specific dimensions, various alloys, and/or different surface finishes. Time and cost will be positively affected if the manufacturer can accept custom orders.

- Prices: While you do need to stay within a certain budget, you must remember that a cheap quote can mean cutting corners on quality. The best strategy is to ask for the specific details you need from as many different manufacturers as you can.

- Delivering on Time: Large projects really emphasize the need for timely delivery. Choose a supplier who can meet deadlines and has safe delivery methods.

With over ten years in the industry, Lanren produces high-quality aluminum circles for multiple uses. Lanren aluminum circles for cookware, automotive components, and packaging. Lanren’s commitment to quality control tests each aluminum circle to ensure reliability and optimal performance. For all your aluminum circle requirements, considering the quality, reasonable pricing, and consistency in customized choices, Lanren remains the best choice.

For any concerns regarding aluminum circles, please contact us.