3003 vs. 5052 Aluminum: What are the Main Differences

Have you ever tried choosing the right aluminum alloy for cookware, lighting, or even automotive parts and got stuck on what to use? 3003 or 5052 aluminum?

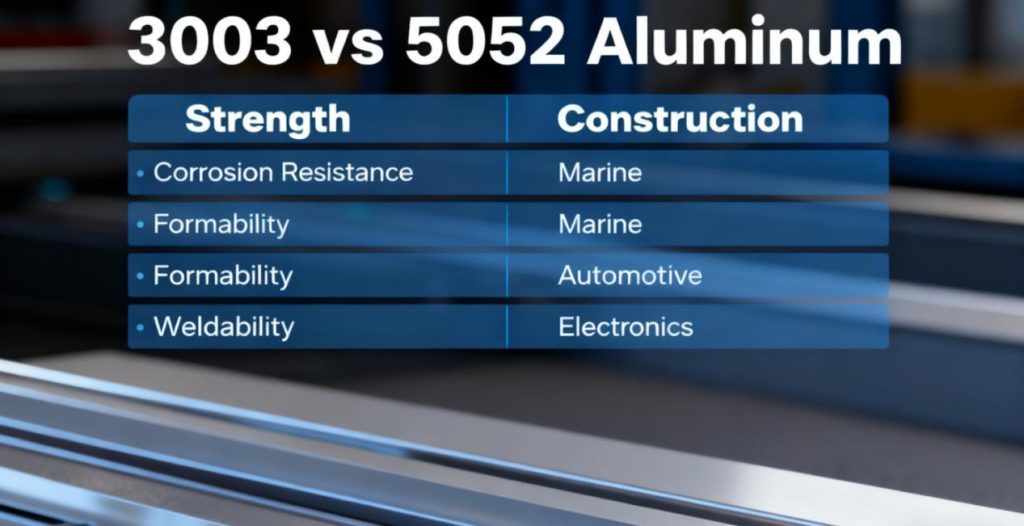

At first glance, these two alloys are nearly impossible to tell apart from each other — both are non-heat-treatable and well known for their excellent corrosion resistance. But in real-life production environments, they could play out very differently in terms of performance, cost, and processing behavior. Getting the wrong grade could lead to cracking during deep drawing, unnecessary material loss, or even product failure under aggressive conditions.

That’s why we need to understand the real difference between 3003 vs 5052 aluminum. This article breaks down the technical differences, mechanical and chemical properties, and best applications of 3003 aluminium and 5052 aluminium so you can make the best choice for your project — whether it’s cookware, a traffic sign, or a boat part.

Understanding the Basics of 3003 vs 5052 Aluminum

In comparing 3003 and 5052 aluminium, manufacturers are essentially comparing two closely appearing but vastly different-performing alloys in real production. Neither is heat-treatable and are very corrosion-resistant but the difference is in their alloying elements — manganese for 3003 aluminium and magnesium for 5052 aluminium — which determine strength, formability, and cost.

| Property | 3003 Aluminium | 5052 Aluminium |

| Main Alloying Element | Manganese (Mn) | Magnesium (Mg) |

| Strength | Medium | Higher |

| Corrosion Resistance | Good | Excellent |

| Formability | Excellent (ideal for deep drawing) | Good |

| Weldability | Excellent | Excellent |

| Relative Cost | More economical | Slightly higher |

| Typical Applications | Cookware, signage, lighting reflectors | Marine parts, automotive components, outdoor panels |

Generally, 3003 aluminum is used for its bright finish and good formability — perfect for cookware and decorative items.

Conversely, 5052 aluminum is more strengthened and corrosion resistant, thus more suitable for applications where marine or automotive applications are most critical in terms of strength.

Mechanical and Chemical Properties Comparison

Begin with an explanation of the reason fueling the behavior.

- Alloy 3003, an Aluminum-Manganese series component of the 3000 series Aluminium alloys, gets the strength boost from manganese and retains notable ductility. This is, in our experience, what makes it the champion of formability.

- The Alloy 500 series is Aluminium-Magnesium series with High magnesium content alloys which makes it with superior strength, which makes it withstands corrosion, particularly from saltwater. This is the Alloy you choose when you need robustness.

| Property | 3003 Aluminium | 5052 Aluminium |

| Tensile Strength | 110–130 MPa | 210–230 MPa |

| Yield Strength | ~95 MPa | ~190 MPa |

| Elongation | 20–35% | 12–20% |

| Hardness (HB) | 35–45 | 60–70 |

| Corrosion Resistance | Good | Excellent, especially against saltwater and chemicals |

| Deep Drawing / Spinning | Outstanding | Moderate to good |

Identifying the alloy is only half the task. The temper (e.g., O, H12, H32, H34) is what determines the ‘personality’ of your aluminium disc.

- O (Annealed): This is the softest state. For 3003, this is the best for the most demanding spinning and deep-drawing operations. For 5052, the O-temper makes forming possible, even though it still requires more force than 3003.

- H32 (Strain Hardened & Stabilized): This is a very common temper for 5052. It offers a superb balance, giving you much of the alloy’s inherent strength while retaining enough formability for moderate bending and shaping.

- H14/H24 (Fully Hard): These tempers are used when maximum strength from work-hardening is needed but formability is very limited.

Our Pro Tip: Don’t simply order “5052” or “3003.” Consult your aluminium circle manufacturer about your entire fabrication process. Indicate whether you plan to weld, spin, or bend the material. This enables us to suggest not only the appropriate alloy but the exact temper that will work best in your press and in the end performance of your product. This will save you from expensive cracking, springback, and premature failure.

Applications Fields of 3003 vs 5052 Aluminum

Understanding the right aluminum alloy to use for aluminum circles isn’t just a matter of metallurgy; it’s a matter of real-world application of the various product strengths of the different alloys. Here at our aluminum circles factory, each of the aluminum circle alloys we use is specifically designed to meet certain product strengths. Here is how they should be applied.

3003 Aluminum Applications Fields

3003 aluminum circles are one of the most ductile aluminum circles, which is why they are used to make complex, deep-drawn shapes in a variety of industries.

- Cookware and Kitchen Utensils: A textbook application. With the use of spinning and deep drawing, the 3003 O-temper aluminum is vital during the creation of pots, pans, and rice cooker bowls. Since it stretches and forms and distributes evenly throughout the bowl, this provides a flawless finish and a greatly increased yield.

- Lighting Industry: 3003 aluminum is ideal for lamp shades, reflector shells, and other lighting fixtures that require a good finish for anodizing and precise shapes. You will find that 3003 aluminum is very workable and economically efficient.

- General Ornamental and Architectural Trims: 3003 is also very suitable in cases that are ornamental and of little structural relevance, and for finishing. It works exceptionally well for nameplates, ornamental curtains, and other slices of interior woodwork trims.

5052 Aluminum Applications Fields

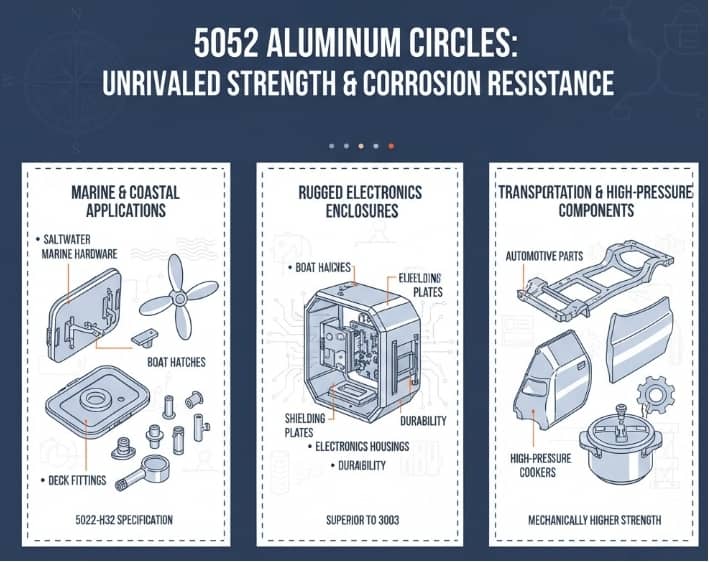

When dealing with powerful forces, extreme pressure, or complicated environments, turning to 5052 aluminum circles is your best bet. This aluminum alloy delivers on all the essential mechanical advantages and provides exceptional corrosion resistance, making it perfectly fit for its designated purpose and application.

- Marine and Coastal Applications: In the world of aluminum alloys, 5052 has a reputation for providing excellent resistance to corrosion caused by harsh marine conditions. Saltwater marine hardware, boat hatches, and deck fittings parts are some of the practical uses of 5052. As an aluminum circle exporter, 5052-H32 is the specification we use for these purposes with utmost confidence.

- Rugged Electronics Enclosures and Chassis: In electronics housings, particularly those that need shielding, durability is a critical attribute along with light weight, and 5052 maintains the structural integrity in these applications, where 3003 simply lacks and instead brings considerable weight.

- Transportation and Components Under High Pressure: In automotive parts, vehicle panels, and especially in the bodies of high-pressure cookers, the mechanically higher strength of 5052 is invaluable. It greatly surpasses internal pressure and mechanical stress on it, and it is critical to the safety and longevity of these products.

How to Source High-Quality Aluminium Circles from Reliable Manufacturers

Getting quality, dependable aluminium circles is not just a matter of price comparison. As a manufacturer ourselves, we advise potential partners to consider two vital factors: technical verification and manufacturing capability.

- First, put technical expertise. Your genuine partner will challenge your application—posing questions about forming techniques, welding, and end-use environment—to recommend the ideal alloy and temper, not merely process an order. Technical conversation like this is invaluable.

- Second, demand quality proof. Always ask for a Mill Test Certificate (MTC); it is the primary certificate that confirms the chemical and mechanical characteristics of your material. Also, assess the manufacturer’s capability for consistency. Question them regarding their blanking and edge-finishing processes to ensure you get clean, burr-free aluminum discs with consistent thickness, batch after batch.

By joining up with a manufacturer that displays this sort of technical support and quality control, you are not merely buying metal—you are buying dependability in your final product.

Summary

Hence, the choice is easy: apply 3003 aluminum circles for greater formability in applications like cookware and lighting. Apply 5052 aluminium circles if your project demands a higher strength, excellent weldability, and improved corrosion resistance for marine or structural applications.

Being your manufacturing partner, we provide you with the right grade and expert guidance to take your product to success. Just let us know in case you need anything!

Related Products