Aluminum Foil vs Tin Foil: What’s the Difference?

In daily operations of food service supply chains, food processing and hotel kitchens, choosing between aluminum and tin foil is no simple procurement task. Poor selection causes food waste, equipment faults and even food safety compliance risks—like a chain barbecue brand’s frequent oven cleaning from low-melting-point foil, or a prepared meal factory’s rework over metal leaching. These hidden costs come from lacking understanding of the two foils’ core differences.

This article breaks down their material processes, performance limits and scenario adaptation logic, offering a professional decision-making framework for procurement teams in catering, food manufacturing and hotels.

Different materials and processes of aluminum foil and tin foil

The fundamental difference between aluminum foil and tin foil lies in their raw material properties and industrial production logic, which directly determines the “large-scale procurement feasibility” for buyers.

Aluminum Foil

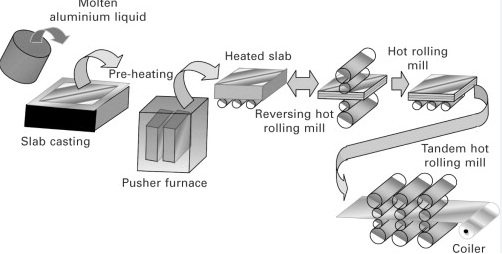

Aluminum foil is made from bauxite, with a global annual mining volume exceeding 300 million tons. Its industrial production chain is highly mature:

- Smelting stage: Bauxite is converted into aluminum ingots via the “Bayer process + electrolysis”. A single production line can achieve an annual capacity of 500,000 tons, with continuously optimized energy consumption—electricity use per ton of aluminum has dropped by 18% compared to a decade ago.

- Rolling stage: The “hot rolling + multi-pass cold rolling” process can reduce aluminum ingots to an ultra-thin 0.006mm, with a stable yield rate of over 98%.

- Coating stage: The “silicon coating process” for food-grade aluminum foil is fully covered by automated lines. It only adds 0.03 yuan per square meter to the cost but reduces aluminum leaching risk by 90%.

This industrial advantage translates directly to procurement cost benefits: a roll of commercial aluminum foil (12μm thick, 500 meters long) costs about 80 yuan wholesale, meeting a medium-sized restaurant’s high-frequency monthly needs (e.g., grilling meat/vegetables, food insulation).engthened and corrosion resistant, thus more suitable for applications where marine or automotive applications are most critical in terms of strength.

Tin Foil

Authentic tin foil is made from cassiterite, with a global annual mining volume of less than 300,000 tons. Its production chain has inherent limitations:

- Smelting stage: Tin ore smelting consumes 3x more energy than aluminum, and a single furnace’s capacity is only 1/20 that of aluminum, making large-scale production extremely difficult.

- Rolling stage: Tin has poor ductility—when rolled to 0.01mm, the fracture risk surges, resulting in a yield rate of less than 70%.

- Anti-adhesion stage: Each tin foil sheet requires manual separation with cotton paper, accounting for 35% of the total labor cost.

Different appearance characteristics of aluminum foil and tin foil

For the catering and food industries, the appearance distinguishability aluminum foil and tin foil are directly linked to “kitchen error rates” and “equipment loss costs,” making a standardized identification and testing system essential.

A systematic approach helps avoid misprocurement, with clear criteria for three core dimensions:

| Identification Dimension | Aluminum Foil Features | Tin Foil Features | Procurement Quality Check Actions |

| Color | Cool silver with strong metallic luster | Warm gray-silver with soft, blue-tinged luster | Randomly select 3 rolls, compare color difference under natural light; a difference >20% indicates “mixed material delivery.” |

| Tactile Sensation | Stiff yet flexible, rebounds after folding | Soft and wrinkle-prone, no rebound after folding | Knead samples into 5cm-diameter balls; unfolded damage area >5% indicates “tin foil contamination.” |

| Packaging | Rolled with cutter, no interlayer paper | Sheet-like with cotton paper interlayer, no cutter | Check packaging; “rolled form with cotton paper” indicates “selling aluminum foil as tin foil.” |

Different physical and chemical properties of aluminum foil and tin foil

The differences in physical and chemical properties between aluminum foil and tin foil are the core basis for determining their application scenarios, directly affecting usage safety and stability, which can be clearly distinguished from two dimensions.

Physical Properties

There are substantial variations in high-temperature resistance structural strength, as well as energy transfer performance between these two materials, with clear application boundaries:

Melting Point and High-Temperature Resistant: The aluminum foil is able to withstand high temperatures with a melting temperature of 660degC. It is able to withstand temperatures of 200 to 300 degrees Celsius without deforming or softening during the long-term use. Tin foil, which has a melting temperature of 232°C, is softened as temperatures rise above 200°C and is prone to melting and breaking when temperatures are high, making it unsuitable for high temperature cooking.

Structural Strength & Tear Resistance: Aluminum foil is in compliance with the standards of the nation regarding tear resistance (>5N) It has a strong toughness, which prevents breakage while wrapping or folding food items, ensuring shape stability. Tin foil has a weak tear-resistant (<2N) and is brittle and susceptible to wrinkles, and can easily tear when exposed to physical force or sharp objects not being able to wrap food securely.

Heating Conduction Uniformity: Aluminium is stable in heat conduction, with a deviance of less than 5 percent, which ensures even heating of food items and keeping out any excessive local temperature differences. Tin foil is not a good heat conduction homogeneity with greater than 15% deviation which can result in local overheating or inadequate heating in the course of use, affecting the results of food processing.

Chemical Properties

Chemical properties, which are that are reflected in the risk of metal leaching are essential for food contact safety.

Aluminium Foil is a material with excellent chemical stability. In contact with neutral food items, the aluminum leaching rate is <0.5mg/kg which is well below the limit of 100 mg/kg set within GB 2762. Even in the event of contact with food that is acidic (pH<3) the leaching grows to a maximum of 2-3 mg/kg, and remains within the safe limits of compliance.

Tin Foil: It is a weak chemical stability. Tin leaching can reach 5-8 mg/kg it comes into contact with neutral food and when it comes into contact with salty or acidic food items, the leaching rate increases to 50-80 mg/kg, which is far more than the 20mg/kg limit for food safety and posing risk to food safety compliance.

Which is better, aluminum foil or tin foil?

There is no universal “better” option—choice depends on catering and food industry scenarios, with decisions guided by material properties and performance.

For chain catering (Chinese cuisine, barbecue, baking), aluminum foil is the standard choice. Opt for 12-15μm high-toughness aluminum foil (balancing tear resistance and cost) and prioritize matte-side contact with food to reduce burning. Annual framework agreements can cap procurement costs below 0.3% of total food costs.

In central kitchens (prepared meals, group meals), aluminum foil ensures scalability. Choose coated aluminum foil (aluminum leaching <0.1mg/kg for HACCP compliance) and pair with automated lines to cut packaging time from 15s to 5s per serving. An 80% recycling rate lowers material costs by 15%.

For high-end catering (Michelin, Japanese, Omakase), tin foil acts as a niche tool. Use food-grade pure tin foil (tin leaching <5mg/kg) for food shaping/decoration. Staff training in hand-shaping can boost customer spending (e.g., a Japanese restaurant raised prices by 30% with tin-wrapped wagyu), but costs must stay under 1.5% per customer.

In food processing (canned goods, condiments), aluminum foil is compliance-focused. Select aluminum-PE composite foil for barrier/tearability, extending shelf life by 6 months. Joint leaching tests with suppliers ensure consistency, and scaling procurement or industry standard participation can cut costs by 22%.

Summary

For food service/manufacturing procurement teams, choosing aluminum vs. tin foil depends on scenario, not general superiority. Aluminum foil, with its mature chain and cost benefits, dominates large-scale uses (chain catering, central kitchens, food processing). Tin foil, valued for malleability, is a niche tool for high-end catering’s presentation needs.

Ultimately, right foil choices reflect refined management, turning consumable buys into operational stability drivers for competitive food businesses.and expert guidance to take your product to success. Just let us know in case you need anything!

Related Products