PVDF vs. PE: A Quick Look at Types for Color Coated Aluminium Coils

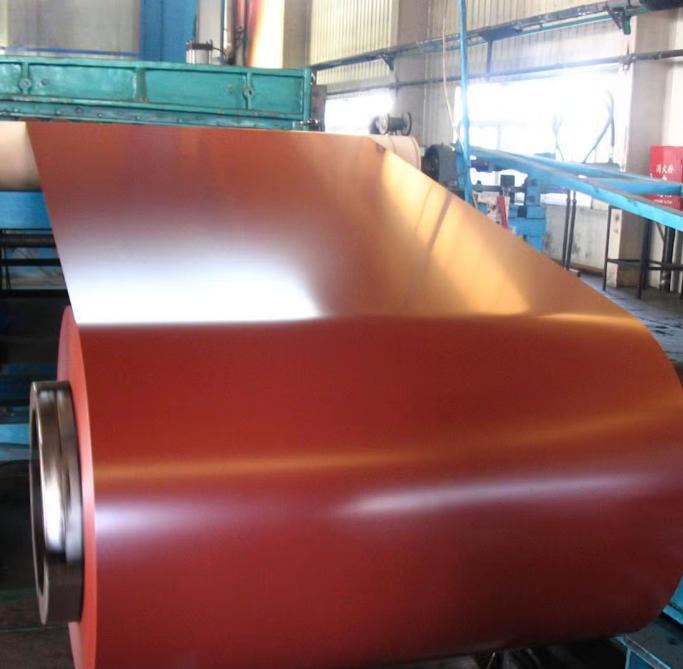

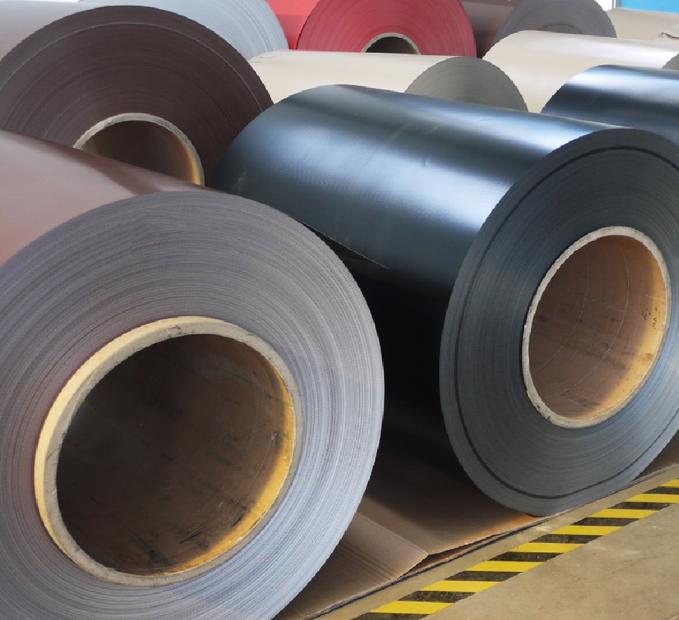

In daily life, color-coated aluminum coils are widely used in the construction of ceilings, roofs, building facades, composite panels, and decorations etc. Its popularity stems from the many properties of aluminium: light weight, corrosion resistance, and its own protective coating that enhances durability and aesthetics.

The appropriate coating – usually PVDF (polyvinylidene fluoride) or PE (polyester) – will directly affect the performance, service life, and later maintenance of the finished product.

Before making a choice, it’s advisable to first understand the differences between them to ensure that your project strikes a perfect balance between aesthetics, protection, and cost-effectiveness. For details, please see below.

What’s the Role of Coatings in Color Coated Aluminium Coil?

The coating is the key factor that makes plain aluminium so strong and pretty. With a color-coated aluminium coil, the coating does more than simply add color — it provides long-term protection and enhances the performance of the metal in everyday conditions.

Each coil is built up with a multilayer coating process, typically made up of:

- Base aluminium sheet: the structural foundation has the properties of light weight and corrosion resistance.

- Primer layer: assists in realizing hard bonding between the aluminium surface and the topcoat.

- Topcoat (PVDF or PE): gives color, gloss, and protection against UV rays, rain, and dirt.

- Back coat: provides a secondary layer of protection and equilibrium for coil stability.

All of these layers combined form a barrier that resists corrosion, fading, and oxidation — even at extremely high temperatures or humidity. Briefly, the coating not only specifies the look of the coil; it specifies its function. The optimal choice of coating system guarantees buildings their color hold, reduced maintenance requirements, and long-term value. For this reason, types of coatings, such as PVDF and PE, need to be learned before selecting the suitable aluminium coil to use.

Comparing PVDF and PE Coated Aluminium Coil

Among all coating systems, PVDF and PE stand out as the two most common choices. Each offers distinct advantages depending on where and how the material is used.

PVDF Coated Aluminium Coil — Premium Protection and Longevity

PVDF coating (polyvinylidene fluoride) is acrylic and fluorocarbon resin-based, creating a highly stable film that protects aluminium surfaces from corrosion, color fade, and ultraviolet light. The high chemical bonds of PVDF make it one of the most reliable coatings for long-term exterior performance.

The main advantages include:

- Remarkable resistance against UV radiation, acid rain, and pollutants.

- Great color hold — maintains color and gloss for over two decades.

- Shining surface finish with good adhesion and resistance to chemicals.

- Low maintenance, ideal for extreme climates and high-end projects.

Thanks to these characteristics, PVDF-coated aluminum coils are used in architectural façades, curtain walls, and roofing, where both beauty and durability are of utmost significance. For materials expected to have long life and superior color stability, PVDF remains the best.

PE Coated Aluminium Coil — Economical and Versatile for Everyday Use

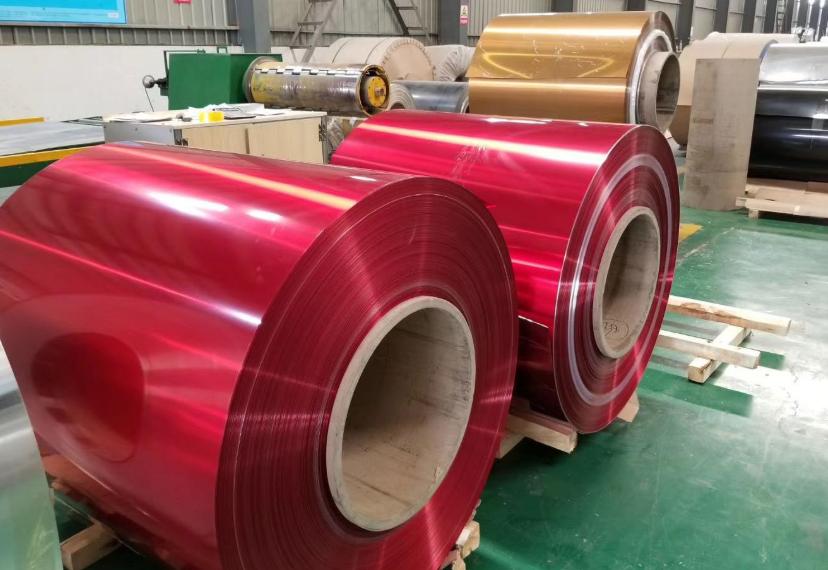

PE coating (polyester) offers a more cost-effective and versatile alternative. It’s made from polyester resin and pigment and offers bright, custom colors with superior forming ability — perfect for bending, cutting, or complex shapes. While its UV resistance is not as high as PVDF, PE coating provides more than adequate protection in benign environments and interior applications.

Principal benefits:

- Large color palette and finishes on offer to support design flexibility.

- Good surface smoothness and high processing adaptability.

- Lower cost, suitable for large areas or decorative use.

- Easy to repair, repaint, or clean whenever needed.

PE-coated aluminum coils are extensively used for ceiling panels, interior walls, signage, and display boards — use cases where cost-effectiveness and appearance matter the most. It is a handy choice for use on a daily basis when critical weather resistance is not a consideration.

Comparison Table

From the above content, we can make this comparison table to summarize the key differences between PVDF and PE coated aluminium coil:

| Feature | PVDF Coated Aluminium Coil | PE Coated Aluminium Coil |

| Weather Resistance | Excellent (20–30 years outdoors) | Good (5–10 years outdoors) |

| UV Resistance | Superior | Moderate |

| Flexibility | Good | Excellent |

| Color Retention | Long-lasting | Moderate |

| Surface Finish | Smooth, elegant matte or gloss | Bright and colorful |

| Cost | Higher | Lower |

| Typical Use | Exterior façades, roofing, curtain walls | Interior panels, signage, decoration |

In a word, PVDF coating delivers top-tier protection and performance, making it ideal for demanding outdoor environments, while PE coating provides a cost-effective and visually appealing option for interior or decorative applications. Choosing the right coating for your color-coated aluminium coil ultimately depends on your project’s location, expected lifespan, and design requirements.

How to Maintain and Extend the Life of Your Color Coated Aluminium Coil?

Regardless of whether a PVDF or PE-coated aluminium coil is chosen, maintenance is required for optimal performance and to maintain appearance. Even the advanced coatings need to be serviced — especially for exposures to sun, water, or air pollution. Properly maintained color-coated aluminium coil can easily outlast expectations in maintaining color, gloss, and protective qualities.

Some helpful tips for taking care of your coated aluminium coils well are as follows:

1. Clean the surface regularly

The surface may be cleaned using clean water or mild neutral detergents to remove dust, salt, and industrial residues. Never use abrasive materials or harsh chemicals that would damage the coating surface.

2. Inspect periodically

The joints, edges, and fasteners need to be checked for corrosion, scratches, or peeling. Early detection allows easy repair and prevents further damage. Handle with care during installation. Prevent friction and impact between metal sheets to avoid micro-scratches or bending that could weaken the coating layer. Always store coils in dry, ventilated areas.

3. Treat it with care during the installation process

Prevent friction and contact between metal sheets to avoid micro-scratches or bending, which could jeopardize the coating layer. Store coils always in dry, ventilated areas.

4. Clean after construction operations

If the coils are used for building constructions, clean off cement dust, sealant, or chemical residue, which could react with the coating surface.

5. Choose reliable suppliers and certified materials

Working with reputable manufacturers utilizing certified coating systems (meeting standards such as ISO or ASTM) ensures consistency of quality and high long-term performance.

By following these easy steps, not only do you maintain your aluminium panels in appearance as bright and clean as when new, but also protect the underlying metal structure. In the long run, an extra small investment in maintenance rewards by increasing the service life of your color coated aluminium coil while reducing repair costs.

Final

Each of the PVDF and PE coatings has its niche in the market for aluminium coils. PVDF provides high-end protection and durability and is therefore suitable for demanding exterior use, while PE is a cost-effective solution that is flexible for indoor and design uses.

To attain the best return, the ideal choice is to partner with expert suppliers since they have the capability to deliver technical knowledge, reliable coating systems, and high-quality products.

Need suggestions for your business? Email us for personalized solutions.

Related Products