Aluminum Coil Vs Copper Coil In HVAC System-Which is Better?

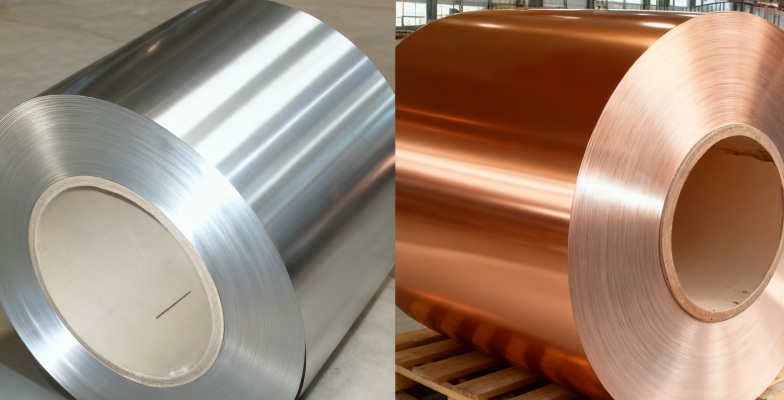

Among the core components of a heating, ventilation, and air conditioning (HVAC) system, the material selection of condenser coils directly impacts the system’s efficiency, lifespan, and operating costs. As two mainstream coil materials, copper and aluminum have long sparked intense debates between “performance advocates” and “cost advocates.”

This article will deeply analyze the differences between copper and aluminum coils from dimensions like performance, cost, installation & maintenance, and scenario adaptability. It provides a professional and practical selection guide for facility managers, engineering contractors, and homeowners, helping you find the most suitable solution in the “copper vs. aluminum debate.”

Copper and Aluminum Coil Performance Difference

1. Thermal Conductivity and Heat Transfer Efficiency

Heat transfer efficiency directly impacts HVAC systems’ Coefficient of Performance (COP), with thermal conductivity as the core factor. Copper coils have a thermal conductivity of up to 400 W/m·K—nearly double aluminum’s. For the same heat transfer need, their size can be reduced by over 30%, enabling compact integration, ideal for space-constrained commercial equipment like large chillers. Aluminum coils (205 W/m·K) have good but inferior heat transfer; to match copper’s effect, they need 30-40% more surface area, making equipment bulkier with looser installation space demands. Copper’s efficient heat transfer cuts “useless losses” in refrigerant circulation, boosting COP by 10-15%. Aluminum, though less efficient, meets “acceptable” energy standards in ordinary residences.

2. Durability and Service Life

Coil service life determines HVAC lifecycle costs, with material physical stability key. Copper coils last over 15 years in most environments; even in harsh coastal high-salt spray or industrial high-pollution areas, their structure remains intact (e.g., a coastal commercial complex’s copper-coil ACs had no obvious core corrosion after 18 years). Aluminum coils last 8-12 years in dry, controlled indoor environments but need frequent maintenance (e.g., cleaning, fin repair) to extend life. In high-humidity, highly corrosive environments, their life may shorten to 5-7 years.

3. Corrosion Resistance Evaluation

Corrosion resistance ensures coil stability in complex environments, critical for coastal/industrial scenarios. Copper forms a dense natural oxide film, resisting salt spray, industrial waste gas, and hard water scaling, with minimal galvanic corrosion risk (e.g., near chemical plants, copper-coil AC corrosion is 1/5 that of aluminum).

Aluminum performs well in interiors that are dry. Its corrosion resistance comes from a thin layer of natural oxide. It is susceptible to galvanic corrosive corrosion when it touches copper (aluminum oxides more quickly as an anode). If you are using coils along the coast, it is important to apply extra anti-corrosion coats and perform 2-3 annual maintenance. Otherwise, they may leak in 5 years.

Copper and Aluminum Coil Price Comparison

Initial Investment

The initial investment is determined by the raw material costs and complexity of processing.

Copper coils are more expensive than aluminum coils due to high copper prices, precision processing equipment, and other factors. Copper coils can cost up to 20,000 yuan more for a chiller condenser.

Aluminum coils are a good choice for large-scale residential construction and small-to medium-sized commercial projects with a tight budget.

Lifecycle Cost (LCC)

LCC is a combination of initial investment, energy losses, maintenance fees and replacement cycles.

Copper coils are expensive upfront, but have a low LCC. They save between 10-15% annually on electricity and require maintenance once every 3 to 5 years. They last for 15 years or more.

Aluminum coils are low-cost initially, but have a higher LCC when used in harsh environments. They need to be replaced every 8-12 (5-7 in harsher areas) years and require annual maintenance.fade, and ultraviolet light. The high chemical bonds of PVDF make it one of the most reliable coatings for long-term exterior performance.

| Cost Dimension | Copper Coils | Aluminum Coils |

| Initial Cost | High (+40-60%) | Low (-40-60%) |

| Energy Loss | Low (10-15% annual savings) | High (5-10% annual increase) |

| Maintenance Cost | Low (3-5 years/once) | High (1 year/once; 2 years/once in harsh areas) |

| Replacement Cycle | 15+ years | 8-12 years (5-7 in harsh areas) |

Difference Between Installation and Maintenance

Best Installation Practices

The physical properties of coil materials dictate the installation process; incorrect installation leads to system failures.

Copper coils: Support flaring, compression, brazing–mature, compatible processes. Prioritize “brazing” quality (to avoid refrigerant leaks due to poor soldering). Also, “refrigerant extraction” (to prevent air from affecting efficiency) should be prioritized.

Aluminum coils: Need anti-galvanic protection (e.g. insulating seals, gaskets compatible with copper and aluminum separation). Lighter weight (30-40%) for easier installation. Low mechanical strength, however, requires that collision damage is avoided during handling.

Both require post-installation pressure testing (leak checks), cooling/heating effectiveness verification, and thorough cleaning of internal residues before startup.

Maintenance Protocols

Maintenance frequency/methods affect coil lifespan, requiring material-specific steps.

Copper coils: Allow “high-pressure washing + chemicals” to remove dust, oil, mold. Maintain every 3-5 years; low cost.

Aluminum coils: Need gentle cleaning (avoids oxide layer damage), regular fin straightening, anti-corrosion coating. Annual indoor maintenance; every 2 years in coastal/industrial areas—costs 2-3x copper’s.

Common requirements: Professional maintenance must include refrigerant level monitoring, electrical connection checks, and system performance testing.

Material Compatibility-Copper-Aluminum Hybrid Solutions

Hybrid solutions are a good option for those who don’t like the cost of pure copper or the performance of pure aluminum. They balance both aspects.

These hybrids combine copper tubes with aluminum fins. Copper tubes ensure strong thermal conductivity, corrosion resistance and refrigerant transportation. Aluminum fins increase the heat transfer surface to reduce costs.

Hybrids are protected by anti-corrosion materials such as epoxy and compatible connectors, like copper-aluminum joint. These elements all work together to stop galvanic corrosion. To ensure quality, the products undergo strict pressure and salt spray tests before they are delivered.

Hybrid solutions are 20-30% more efficient than copper-only systems, and cost 20-25% less. These hybrid solutions are perfect for small to medium commercial projects with limited budgets, such as convenience stores or small offices.

“Golden Rules” for Scenario-Based Decision-Making”

(1) Scenario-Specific Matching

Choose based on environment and needs:

Copper coils: For harsh areas (coastal, industrial, hard water), high-end projects (5-star hotels, labs) and properties held over 10 years (prioritize lifecycle cost).

Aluminum coils: For dry inland residences (budget-limited), properties resold within 5 years (control initial cost) and aluminum system replacements (no performance upgrade needs).

(2) Performance Priority Matrix

| Performance Priority | Material | Core Logic |

| Efficiency (COP) | Copper | Better conductivity, higher COP, long-term electricity savings |

| Corrosion Resistance | Copper | Natural resistance, longer life in harsh environments |

| Initial Cost/Light Install | Aluminum | Lower cost/30-40% lighter, easier to install |

| Long Life/Harsh Environments | Copper | Stable, resists extreme corrosion, avoids frequent replacement costs |

In Conclude

In choosing copper or aluminum coils for HVAC systems, there is no absolute “performance winner” or “cost winner”—only the “most suitable solution” based on application scenarios, ownership duration, and budget constraints.

Copper coils (high performance, long lifespan, strong corrosion resistance) are a “safe choice” for harsh environments and long-held projects. Aluminum coils (low cost, light weight) work as a “cost-effective option” for ordinary residences and short-term projects. Copper-aluminum hybrids balance both as a “compromise solution” for mid-range needs.

Evaluate lifecycle costs (not just initial price) before choosing, prioritize professional installation and maintenance, and consult Lanren Aluminum for customized plans to achieve performance-cost “win-win.”

Related Products