Aluminium Circle vs. Aluminium Sheet: Which One Suits Your Project?

Aluminium is popular in a variety of industries because of its lightness, durability, resistance to corrosion, and superior ability to form. Two commonly used types of aluminum–aluminium circle and aluminium sheet–often have different needs based on the particular task at hand. Knowing their distinctions is essential when choosing the appropriate material for your project. This article explains the advantages, features, and the best applications to assist you in making an informed choice.

What is Aluminium Circle and Aluminium Sheet?

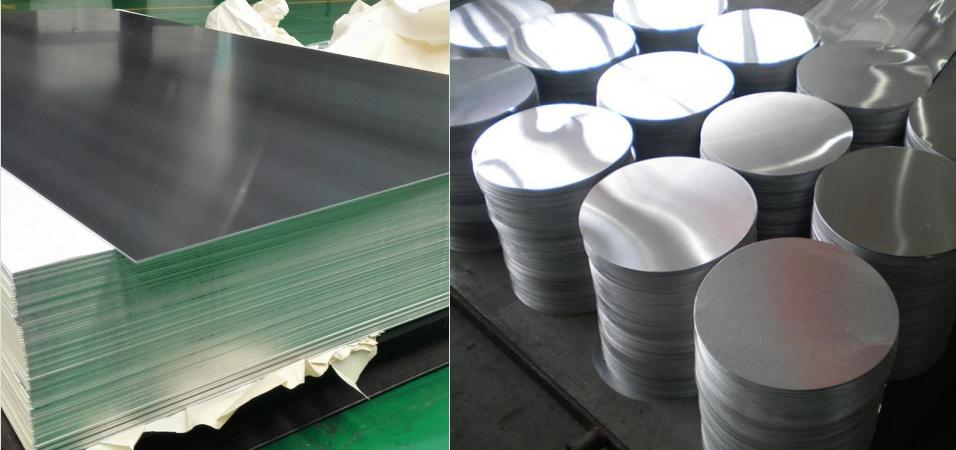

Aluminium Circle is an oval, flat disc made from aluminum sheets or coils. It is usually made by processes such as stamping or blanking, which result in uniform circular shapes that are consistent in size. Aluminum circles are used for industries that need exact round pieces, like cookware (frying pans, lids, pots and pans) as well as lighting reflectors as well and traffic signals. Their smooth surface and shape are ideal for spinning and deep drawing processes, in which material shapeability is vital.

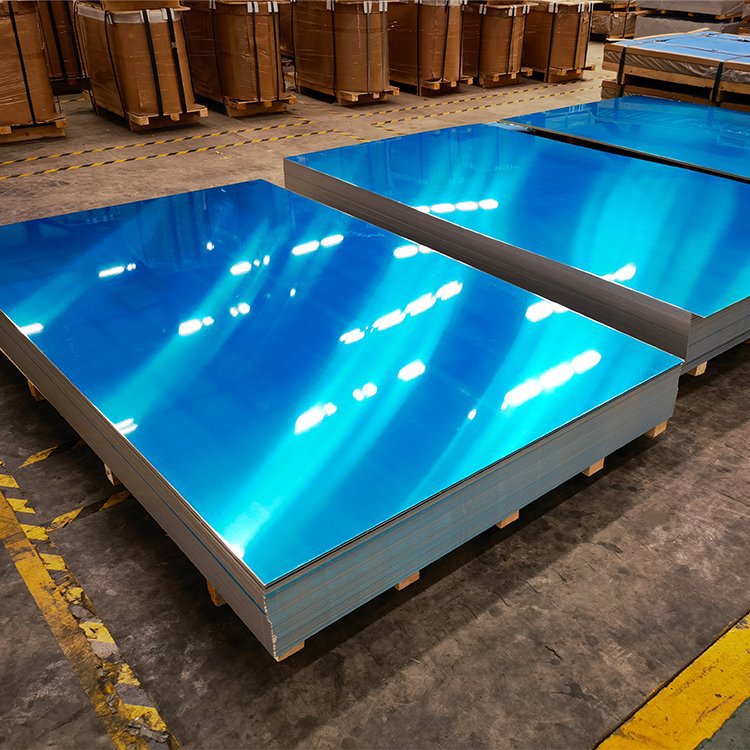

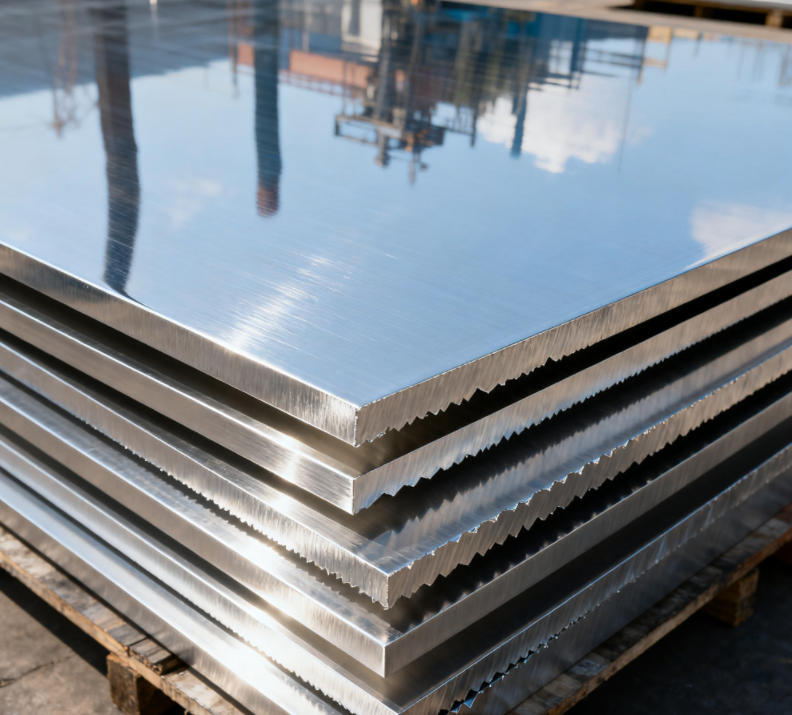

Aluminium Sheet, on the contrary it is a flat-rolled aluminium product that has a rectangular shape. It comes in different sizes, thicknesses, and alloy grades, providing the flexibility to suit a variety of uses. Aluminium sheets are used extensively in the fields of construction, transportation, aerospace, signage, as well as general fabrication. As opposed to circles of aluminium, sheets aren’t limited to one form or shape. They can also be cut or molded in virtually any form.

In essence, aluminium circles are pre-shaped for specific applications, while aluminium sheets offer greater versatility for projects requiring custom shapes and structural flexibility.

Key Differences of Aluminium Circle and Aluminium Sheet

When choosing between aluminium circle and aluminium sheet, here are some main different aspects that you should consider.

Shape and Processing Method

The most fundamental difference between aluminium circles and aluminium sheets lies in their shape and the way they are processed.

- Aluminium Circle

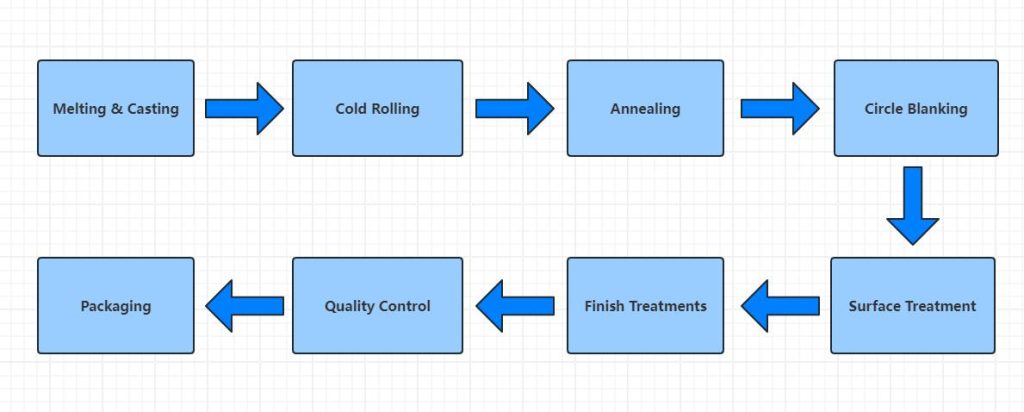

Aluminum circles are produced using round-shaped blanks out of aluminum sheets or coils using methods such as stamping, blanking, or rotating shearing. They are typically straight edges with uniform thickness and precise diameters. They are crucial for applications that require the symmetry and balance of cooking equipment or light reflectors. The process of making them is automated and effective, usually comprising decoiling, leveling, cutting, and finishing the edges in a continuous flow. Because aluminum circles are already formed into their final shape, they require only minimal processes and can be employed in operations such as the deep drawing process or spinning.

- Aluminium Sheet

Aluminium sheets are created through the rolling of aluminium ingots to rectangular panels with different dimensions. They’re rectangular and are available in a broad array of sizes. In contrast to circles, sheets need further fabrication processes, such as cutting, punching, or laser processing, to achieve the exact shape. Sheets are highly adaptable in the design of custom components, however, they are also labor-intensive when complex or round designs are required. Sheets are perfect when you need to be flexible regarding size, shape, and use.

In summary, aluminium circles offer ready-to-use geometry for circular products, while aluminium sheets provide a blank canvas suitable for custom shaping and detailed fabrication.

Typical Application Scenarios

Here we use a sheet to summarize the different applications of aluminium circle and aluminium sheet:

| Industry/Use Case | Aluminium Circle | Aluminium Sheet |

| Cookware & Kitchenware | Pots, pans, lids (deep-drawn/spun). | Baking trays, countertops (cut/bent). |

| Lighting & Electronics | LED reflectors, lamp housings (symmetrical). | Enclosures, heat sinks (flat/machined). |

| Construction | Decorative domes, signage. | Roofing, cladding, partitions. |

| Automotive | Wheel covers, fuel tank caps. | Body panels, chassis parts. |

| Industrial | Pressure vessels, chemical tanks. | Machine guards, conveyor belts. |

| DIY & Art | Sculptures, round art pieces. | Shelving, custom fabrication. |

This table-based format highlights direct comparisons while allowing you to quickly identify the best fit for your industry.

Molding Efficiency and Cost

When comparing aluminium circles and sheets, efficiency and cost depend on your project’s shape and production method.

- Aluminium circles are highly efficient for rotational forming processes like spinning, stamping, or deep drawing. Since they are pre-cut into round blanks, they minimize material waste when manufacturing curved components like cookware or reflectors. However, custom-sized circles may have higher upfront costs due to specialized tooling and lower bulk availability.

- Aluminum sheets, on the contrary, are efficient for bent or flat designs, like enclosures and panels. Standard sizes for sheets (e.g., 4×8 feet) are available in a wide range, cutting down lead times as well as the cost of materials. But cutting circles from sheets creates waste, which increases costs for processing.

In the case of high-volume circular products, circular products are more efficient, and large flat products profit from the cost-effectiveness of sheets. Take into consideration the amount of waste material, as well as tooling requirements, as well as the quantity you need for the best cost option for your job.

Inventory and Customization

In terms of availability and flexibility, aluminum sheets and sheets have distinct advantages according to the requirements of your project.

- The aluminum circles are generally special items that usually require a custom order, because many suppliers don’t have an array of cut dimensions. This is why they are the ideal choice for projects that require precision circular blanks, such as cooking equipment or lighting elements. However, it can lead to long lead times when using unusual diameters or alloys.

- Aluminium sheets, by contrast, are widely available in standard dimensions (like 4×8 ft or 5×10 ft) across various thicknesses and alloys. Their ready availability makes them more convenient for immediate use, while their flat form allows for easy on-site customization through cutting, bending, or machining.

For highly specialized round applications, circles provide exact specifications with minimal post-processing. For flexible, large-scale projects, sheets offer greater accessibility and adaptability. Consider your timeline, customization needs, and supplier capabilities when choosing between the two.

Specification Considerations of Aluminium Circle and Aluminium Sheet

When selecting between aluminium circles and sheets, key specifications must be evaluated to ensure optimal performance for your application. The table below summarizes the critical comparison points:

| Specification | Aluminium Circle | Aluminium Sheet |

| Thickness Range | 0.3mm – 10mm (typically uniform) | 0.2mm – 200mm (wide variability) |

| Common Alloys | 1050, 3003, 5052 (excellent formability) | 6061, 5083, 3105 (structural strength) |

| Standard Sizes | Custom diameters (100mm – 2000mm) | Standard sheets (e.g., 1220×2440mm) |

| Surface Finish | High polish, anodized for aesthetics | Brushed, coated, or mill finish |

| Tolerance | ±0.1mm (precision roundness) | ±0.5mm (depends on cutting method) |

Key Selection Factors:

- Circles provide an even thickness when stamping or spinning sheets, whereas circles offer a greater range of thicknesses for structural use.

- Select 3003/5052 circles to form applications and 6061/5083 sheets to meet load-bearing requirements.

- Sheets have the advantage of size and availability. due to their immediate availability. Circles will require a period of lead time when it comes to specific dimensions.

- Circles work best as decorative surfaces. Sheets work is ideal for architectural or functional finishes.

This comparative structure helps you identify the product that best meets the technical specifications and requirements.

Which Aluminium Products Suit Your Project?

Selecting between aluminium circles and sheets depends on your project’s specific requirements. For round or rotationally symmetric components, such as cookware, lighting reflectors, or decorative items, aluminium circles are the ideal choice. Their pre-formed circular shape minimizes material waste during manufacturing processes like spinning or deep drawing, making them efficient for high-volume production of curved parts.

If your project involves flat or bent structures–including construction panels, automotive parts, or machinery enclosures–aluminium sheets provide greater versatility. It is available in standard sizes, with various dimensions. They are cost-effective for larger-scale projects and are readily bent, cut, or welded according to specific requirements.

Take into consideration the volume of production materials, waste materials, and the fabrication techniques when you make your choice. Circles are a great choice for precision circular products, but they may need special orders. Sheets allow for greater flexibility and quicker access to flat shapes. Analyze your project’s design as well as its structural requirements and budget to decide if sheets or circles will provide the most value and performance.

If you are seeking a reliable aluminium circles and sheets manufacturer, Lanren Aluminium will be a good choice. Contact us for more information!

Related Products