How to Reduce Material Waste When Cutting Aluminum Sheets

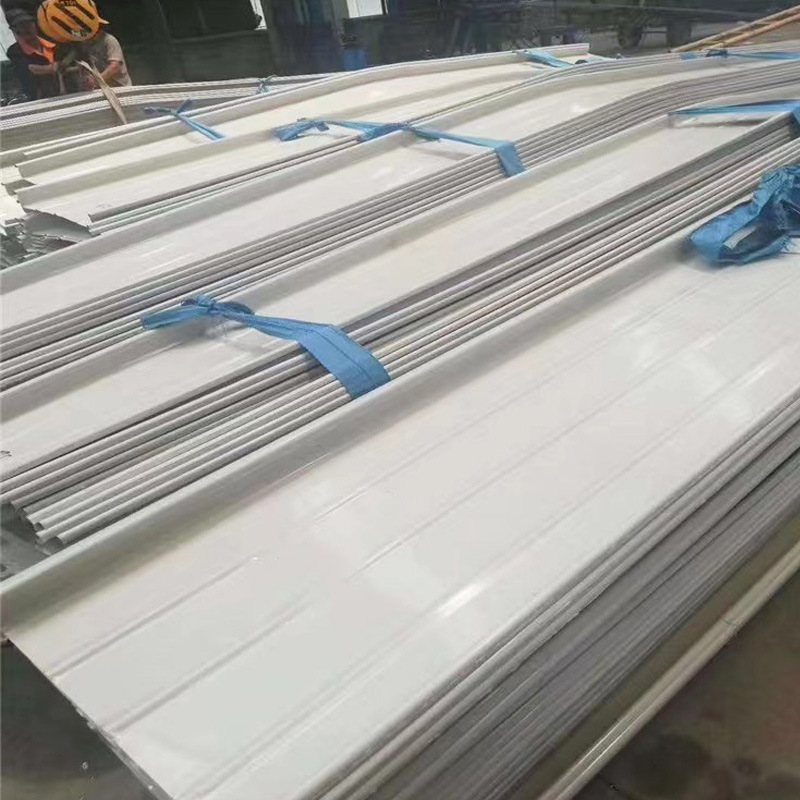

Aluminium is one of the most diverse materials, being used in everything from car production and design through to manufacturing and construction. However, cutting aluminum sheets wastes material, not only harming the environment but also adding to the cost of production; fortunately, some handy techniques and tools can reduce the wastage, streamlining the cutting process to be both more efficient and better for the environment.

Why Reducing Waste in Aluminum Cutting Matters

Metal cutting is lost efficiency and profit; with material prices still escalating and sustainability now the priority, waste reduction in cutting operations has the potential to return three significant advantages. These are:

- Cost Savings: Aluminum sheet scrap directly and immediately affects your bottom line, and a 5- 10% savings can mean significant annual savings, especially among high-volume manufacturers.

- Environmental Advantages: Aluminum is recyclable, but production still requires a lot of energy. Reduced waste means reduced energy utilization and carbon footprint–a top priority for eco-friendly industries.

- Operational Effectiveness: Redundant material leads to additional orders, schedule delays, and wasteful labor expense. With accurate cutting techniques, it provides streamlined production processes and better use of raw materials.

Fields such as construction, automotive, and aviation are particularly interested in minimizing waste to achieve extremely tight budget and sustainability constraints. Streamlining cutting processes or purchasing bespoke-cut aluminum sheets to achieve unique cuts gives businesses an advantage without incurring unnecessary expenses.

Best Tools for Cutting Aluminum Sheets with Minimal Waste

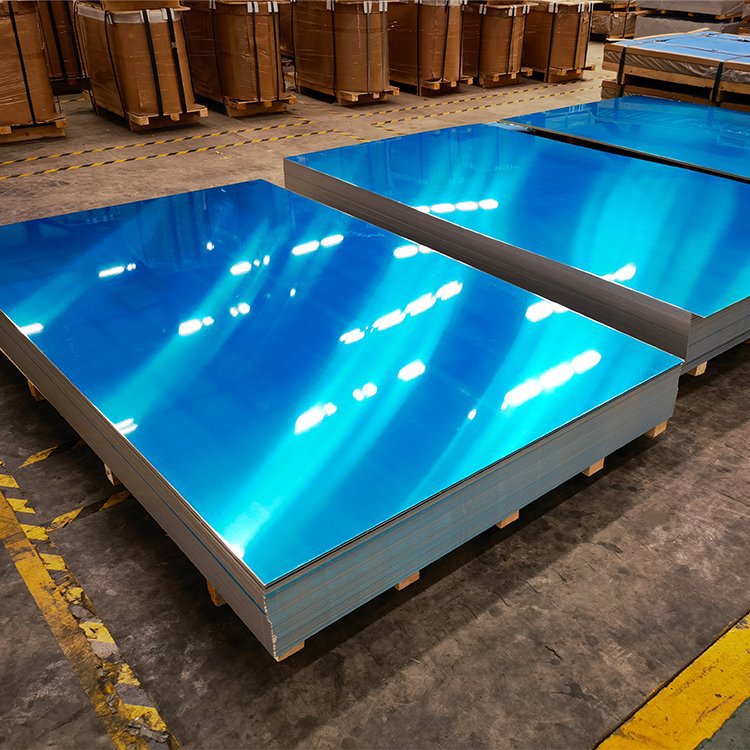

If you want to cut aluminum efficiently, in addition to choosing high-quality aluminum sheets that meets your needs, you also need the right tools to maximize material utilization and reduce waste. The following are the most efficient cutting methods that balance accuracy, speed and reduced waste:

- Laser Cutting for Precision and Thin to Medium Sheets

Laser cutting has excellent accuracy and is an ideal choice for thin, closely toleranced designs. Its kerf width of only 0.1-0.3mm and waste rates of 0.1% to 0.3% compared to standard sawing methods. Its ideal application is on thin to medium-thickness aluminum sheets (0.5-25mm thickness). Typical uses of this manufacturing process are in electronics manufacturing and car manufacturing factories.

Chief Benefit: Minimized material waste owing to accuracy.

2. Water Jet Cutting for Thick Sheets without Heat Distortion

Unlike laser or plasma cutting, the water jet cutting technology utilizes a high-pressure stream of water containing abrasives to cut aluminum without heat distortion, thus preserving material integrity without warping. It has been specially developed to work on heavy sheets of up to 150mm thickness and is now widely employed by the aerospace and marine industries.

Primary Benefit: No heat-affected zones mean less material that is wasted due to warping, conserving resources and dollars in the form of waste material.

- CNC Routing – For Automated, Repeatable Cuts

CNC routers equipped with high-speed spindles and carbide bits provide consistent, repeatable cuts—ideal for bulk orders. Advanced nesting software optimizes sheet layouts, reducing scrap by up to 20% compared to manual cutting. This method is popular in signage, cabinetry, and industrial fabrication.

Key Benefit: Software-driven efficiency maximizes sheet utilization.

4. Shear Cutting vs. Circular Saws – For Simple, Straight Cuts

Shearing is fast and efficient for straight cuts but only with plain shapes.

Circular saws with fine-toothed carbide blades are inexpensive for workshops but require proper technique to avoid ragged edges and wasted material.

Best suited for: Small shops needing quick cuts without sophisticated equipment.

Choosing the Right Tool = Less Waste, Lower Costs

Each method has trade-offs between speed, precision, and cost. For zero-waste cutting, many manufacturers now opt for pre-cut aluminum sheets from suppliers, eliminating in-house scrap entirely.

Techniques to Minimize Cutting Aluminum Sheets Waste

Reducing aluminum sheet cutting waste starts with smart planning and economic cutting methods. One of the most successful methods is nesting optimization—the strategic positioning of components on a sheet to make as much use of the material as possible. Components can be automatically positioned closely together by nesting software, with very little gaps and leftover scrap. The outcome of this method is that additional components can be produced from a single sheet, optimizing yield.

- Selecting the correct tools is equally vital as producing quality aluminum parts. Employ saw blades, cutters, and equipment designed particularly to cut aluminum with the correct material thickness in mind; using fine-tooth blades on thin sheets reduces material loss at the cut and edge damage that could otherwise lead to rejected parts.

- Proper machine calibration – proper speed, pressure, and feed rates – is critical. Cutting too quickly can create warping or burrs and too slowly is wasteful or results in uneven outcomes; ongoing maintenance and calibration of machines result in clean cuts with minimal errors and waste.

- Lastly, accurate measurement and marking off avoid mistakes that cause sheets to be wasted. Double-check the measurements prior to cutting and use proper marking devices to ensure alignment. Proper cuts the first time maximize material use and minimize scrap.

By ensuring strategic planning, correct equipment, and vigilant implementation, manufacturers can efficiently reduce aluminum sheet waste and maximize overall production efficiency.

Benefits of Custom Cut Aluminum Sheet Services

Choosing custom-cut aluminum sheet services can provide many advantages that can simplify operations and reduce wastage of material, including:

- Precision Cutting Services: Custom cutting services employ cutting tools like CNC machines, laser cutters, and water jets to provide very precise cuts, which reduce measurement errors and cut the components to exact specifications to provide minimum material losses and wastage.

- Minimize Waste: Commercial cutting operations frequently employ nesting software to maximize material utilization. By making deliberate cuts, they minimize scrap and make the most of every piece of aluminum sheet for sale.

- Effective Utilization of Time: Custom cut companies specialize in cutting large or complex orders quickly and precisely, speeding up production timelines while reducing in-house cutting-related downtime.

- Quality Assurance and Expertise: Aluminium cutting services provided here are worked on by experts having experience of decades, ensuring consistency and quality in each piece produced. Their techniques have been optimized to produce outstandingly consistent outcomes that guarantee repeatable, repeatable high-quality results every time.

Utilization of special cutting services is an efficient cost-saving method for manufacturers that seek to optimize efficiency and material use.

Reduction of material loss during cutting aluminum sheets is essential for maximizing sustainability, lowering expenses and increasing efficiency. By choosing appropriate tools and implementing effective methods such as custom cut services, businesses are able to save material costs and time significantly, while lowering the environmental impact. From CNC cutters to expert services that focus on aluminium waste reduction reducing aluminum waste is a move towards cleaner production lines.

Related Products